Why Polypropylene (PP) Matters

Ever wondered about that plastic that seems omnipresent in your daily life? From the grip of your toothbrush to the components of your vehicle, Polypropylene is the silent MVP of materials. 🌟

Here’s why you should be intrigued by Polypropylene:

- Ubiquity: It’s not an exaggeration to say that you’ll bump into Polypropylene multiple times a day.

- Functionality: If something feels just right, there’s a high chance PP is behind it.

- Green Credentials: Surprisingly, this plastic is making strides in environmental responsibility.

A Glimpse into the Past

History isn’t just dates and events; it’s the story of evolution. Polypropylene’s narrative began in the 1950s, thanks to the simultaneous discoveries by Karl Ziegler and Giulio Natta. From a lab novelty, it skyrocketed to global prominence, revolutionizing multiple sectors.

Insider Info: Ziegler and Natta didn’t just make a discovery; they bagged a Nobel Prize for it! That’s how monumental their work was.

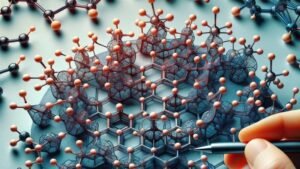

What Makes Polypropylene Tick?

Time to geek out a bit and delve into the unique attributes of Polypropylene:

- Heat Warrior: PP stands tall against high temperatures, ensuring durability and performance.

- Chemical Fortress: It’s the ultimate defense against aggressive chemicals, ensuring longevity in corrosive environments.

- Lightweight Prodigy: In industries where weight matters, PP is a game-changer.

- Powerhouse of Strength: PP is synonymous with resilience, making it indispensable in heavy-duty applications.

- Flex Master: Need adaptability? PP is your answer, perfect for dynamic applications.

- Electrical Sentinel: PP is a maestro at insulating, ensuring safety in electrical applications.

- Impact Maestro: PP is the cushion the world needs against shocks and impacts.

- Transparency Expert: In its pure form, PP offers crystal clear visibility, ideal for showcase packaging.

- Water’s Nemesis: Its natural hydrophobic nature makes it a water-repellent champion.

- UV Warrior: Some PP variants act as a shield against harmful UV rays.

- Smooth Maverick: With PP, think of seamless, frictionless movement.

- Signal Protector: In the realm of electronics, PP ensures signal integrity.

Each of these characteristics carves a niche for Polypropylene in diverse applications.

Crafting with Polypropylene

Transforming this plastic into usable products involves several techniques:

- Injection Molding: The default choice for diverse products.

- Extrusion: Ideal for creating elongated structures.

- Blow Molding: The method behind many containers.

- Thermoforming: The secret behind many packaged goods.

Insider Tip: Your favorite storage containers? They’ve likely been shaped by one of these methods.

PP Varieties at a Glance

| Variant | Features | Typical Uses |

|---|---|---|

| Homopolymers | Renowned for strength | Textiles like carpets |

| Copolymers | Flexibility is key | Films for packaging |

| Block Copolymers | A balance of attributes | Components in vehicles |

Pro Tip: Picking the right grade is crucial. It’s not a one-size-fits-all scenario.

Polypropylene in Action

PP’s adaptability is evident in its myriad applications:

- Packaging: Its attributes make it a favorite for containers and wraps.

- Automotive: PP’s properties make it indispensable in vehicles.

- Textiles: PP fabrics are the unsung heroes in various applications.

- Medical Arena: Its unique properties make it a staple in medical equipment.

- Consumer Realm: From toys to utensils, PP’s versatility shines.

Eco-Considerations

PP’s advantages are many, but its environmental implications warrant attention:

- Recycling Hurdles: While recyclable, PP presents challenges in efficient processing.

- Carbon Concerns: The environmental footprint of PP production is under scrutiny.

- Waste Strategies: Initiatives like EPR aim to manage PP waste better.

Eco Note: The journey to a greener PP is ongoing, with promising strides.

What Lies Ahead

The future of Polypropylene is rife with possibilities:

- Eco PP: Research is on to derive PP from sustainable sources.

- Cutting-Edge Manufacturing: Techniques like nanotech are enhancing PP’s attributes.

- Customized Features: Molecular engineering is paving the way for tailored PP properties.

- Smart PP: The integration of tech elements is ushering in a new era for PP.

- Recycling Innovations: Novel methods aim to recycle PP more efficiently.

- Composite Evolution: PP composites are being refined for specific industry needs.

- Circular Vision: The focus is shifting towards a more sustainable PP lifecycle.

Future Glimpse: The trajectory of Polypropylene is set to be thrilling.

Wrapping Up

Our journey through the realm of Polypropylene has been enlightening. Beyond its omnipresence, it’s evident that Polypropylene is not just another plastic; it’s a material shaping our world.