Introduction

In an era where plastic pollution has burgeoned into a global environmental catastrophe, the quest for sustainable, biodegradable alternatives is more imperative than ever. Each year, millions of tons of plastic waste inundate our oceans, landscapes, and urban areas, posing threats to marine life, terrestrial animals, and even human health. Amid this crisis, the scientific community has been ardently exploring biopolymers — organic materials that not only match the versatility of plastics but also respect the rhythms of nature. Among these, Polyhydroxyalkanoates (PHA) stand out, heralding a new age of materials that beautifully merge utility with sustainability.

Understanding Polyhydroxyalkanoates (PHA)

As we seek alternatives to traditional plastics, a primer on the science behind these novel materials can help us appreciate their potential. So, what exactly are Polyhydroxyalkanoates?

What is PHA?

Polyhydroxyalkanoates (PHA) are naturally occurring polyesters. Synthesized by numerous bacteria as a form of energy and carbon storage, these materials bear a striking resemblance to many of the synthetic plastics we’re accustomed to, both in appearance and function.

Natural Synthesis

Microorganisms play a pivotal role in the world of PHA. In nature, many bacteria produce these polyesters when they find themselves in environments with an abundance of carbon but a dearth of other essential nutrients. In essence, they’re stocking up for leaner times, much as animals might store fat.

Different Types of PHA

While we often refer to PHA in the singular, it’s essential to understand that it’s not a one-size-fits-all substance. There’s a variety of PHAs, each with unique characteristics:

- Poly-3-hydroxybutyrate (PHB): One of the most studied PHAs. While it showcases many of the properties that make plastics so versatile, its brittleness has led to the exploration of other types.

- Poly(3-hydroxybutyrate-co-3-hydroxyvalerate) (PHBV): A copolymer that combines different monomers. PHBV retains many of the desirable qualities of PHB but is more flexible, making it suitable for a wider range of applications.

- And many more, each with its own set of properties and potential applications.

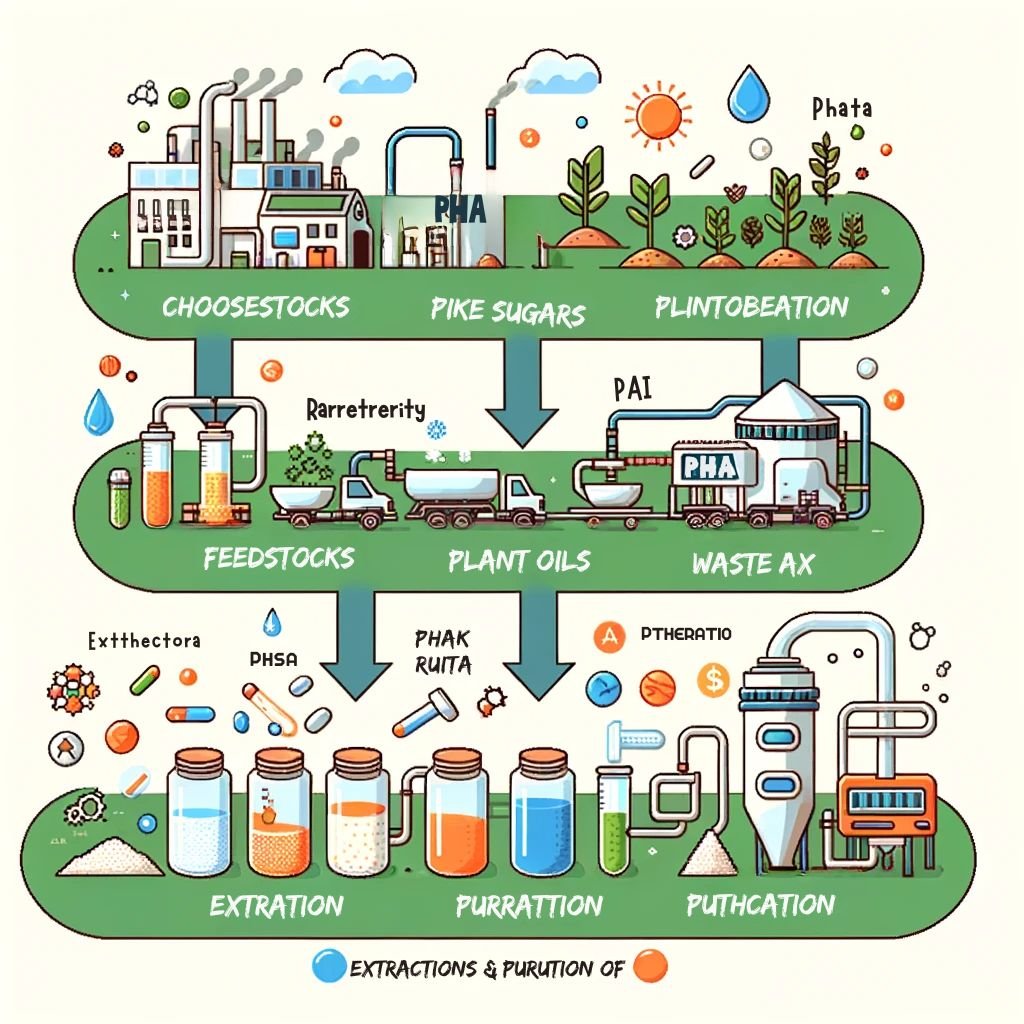

The Production Process

To harness the incredible potential of PHA as a sustainable alternative to traditional plastics, understanding its production is paramount. Let’s break down how this biopolymer goes from basic feedstocks to a finished product.

Feedstock Options

The beauty of PHA lies in its versatility at the very beginning of its lifecycle. PHAs can be derived from a multitude of feedstocks:

- Sugars: Often sourced from crops like sugarcane or corn, these serve as primary carbon sources for microorganisms that produce PHA.

- Plant Oils: These fatty substances can also be metabolized by certain bacteria to produce the desired polymers.

- Waste Streams: Moving towards true sustainability, there’s growing interest in utilizing waste materials, like used cooking oils or even wastewater, as feedstocks.

Microbial Fermentation

Once an appropriate feedstock is chosen, the production magic begins:

- Selection of Microorganism: Different bacteria have affinities for various feedstocks and produce different types of PHA. Hence, choosing the right one is crucial.

- Growth Conditions: The bacteria are nurtured in bioreactors, where conditions like temperature, pH, and nutrient availability are meticulously controlled to optimize PHA production.

- Stress Induction: To maximize PHA content within bacterial cells, certain stresses (like nutrient deprivation) are applied, prompting the microorganisms to produce and store more PHA.

Extraction and Purification

After fermentation, the challenge is to retrieve the PHA from the bacterial cells:

- Cell Harvesting: Once fermentation concludes, the bacterial cells are separated from the remaining liquid using centrifugation or filtration.

- PHA Extraction: The harvested cells undergo processes to break them open, releasing the PHA. Common methods include solvent extraction or mechanical disruption.

- Purification: To ensure the PHA is of high quality, impurities, including residual bacteria, solvents, or other contaminants, are removed.

Tailoring the Production Process

The remarkable thing about PHA is its adaptability. By tweaking the microbial production conditions or even introducing genetic modifications to the bacterial strains, the properties of the resulting PHA can be tailored to fit specific requirements.

Benefits of Using PHA

As the conversation around sustainable materials gains momentum, it’s essential to understand the tangible advantages that make PHA a frontrunner in the realm of biopolymers. Let’s shed light on the myriad benefits that these unique polyesters bring to the table.

Biodegradability

Arguably, the most significant advantage of PHAs is their innate biodegradability:

- Environmental Harmony: Unlike traditional plastics that persist in the environment for hundreds to thousands of years, PHAs can be broken down by a wide range of microorganisms present in diverse ecosystems, from soil to freshwater to marine environments.

- Reduced Plastic Pollution: With the vast majority of plastics ever produced still existing in some form today, PHA offers a solution that doesn’t contribute to this ever-growing environmental issue.

Renewable Resources

The origins of PHA are in stark contrast to petrochemical-derived plastics:

- Plant-based Feedstocks: Derived from renewable resources like sugars and plant oils, PHA production can be inherently more sustainable, especially if sourced responsibly.

- Waste-to-Wealth: The potential of using waste streams as feedstock positions PHA as a champion of the circular economy, converting waste materials into value-added products.

Versatility in Properties

PHA’s diverse family ensures it’s not just a one-trick pony:

- Tailored Performance: As we learned earlier, by adjusting production parameters or using different bacterial strains, PHAs can be engineered to possess specific properties, from flexibility to transparency to strength.

- Blends and Composites: PHA can be blended with other polymers or reinforced with fibers to enhance its properties or to achieve specific characteristics suitable for varied applications.

Safe for Medical Use

One of the unique edges PHA has over many traditional plastics is its biocompatibility:

- Medical Innovations: Being biocompatible and biodegradable, PHA has found applications in the medical field, such as sutures that naturally dissolve over time or drug delivery systems.

Applications of PHA

With its robust list of benefits, it’s no surprise that PHA is carving out a niche in multiple sectors. From the foods we eat to the clothes we wear, let’s explore the expansive landscape of PHA applications.

Packaging

In a world drowning in single-use plastics, PHA offers a breath of fresh air:

- Biodegradable Wraps: PHA can be processed into thin films suitable for food wraps and packaging. Imagine buying a sandwich wrapped in plastic that, once discarded, naturally decomposes!

- Bottles and Containers: Beyond just wraps, PHA has the potential to revolutionize the packaging of beverages and other products, offering a truly biodegradable alternative to PET bottles.

Agriculture

Farmers, too, can reap the benefits of this biopolymer:

- Mulch Films: Instead of conventional plastic mulch that has to be removed and often ends up as waste, PHA-based mulch films can be ploughed directly into the soil after the harvest, where they biodegrade.

- Controlled Release Fertilizers: Encapsulating fertilizers in PHA allows for the slow release of nutrients. As the PHA degrades, the fertilizer is made available to plants.

Medical Field

The marriage of medicine and materials science has brought forth some of PHA’s most exciting applications:

- Sutures: Forget about a second trip to the doctor to get stitches removed. PHA sutures naturally dissolve over time, reducing the risk of scarring and infection.

- Drug Delivery Systems: PHA microspheres can be engineered to deliver drugs over extended periods or at targeted sites, potentially improving therapeutic outcomes and patient compliance.

Consumer Goods

Everyday products are also getting the PHA touch:

- Toys: Imagine toys that, once broken or no longer wanted, can be composted. PHA makes this possible.

- Utensils: From forks to straws, single-use items made of PHA don’t linger for centuries in landfills.

Challenges and Solutions

While PHA promises a future of sustainable materials, the journey towards large-scale adoption isn’t without its hurdles. Addressing these challenges head-on is crucial to truly unlocking the potential of this biopolymer.

Production Cost

Perhaps the most significant barrier to PHA’s widespread adoption:

- Challenge: Currently, producing PHA can be more expensive than manufacturing traditional plastics, primarily due to the costs associated with feedstock and the complexities of microbial fermentation.

- Solution: Researchers are exploring cheaper feedstock options, optimizing production processes, and leveraging genetic engineering to boost yields. As production scales up, economies of scale could also help reduce costs.

Scale-up and Commercialization

Moving from labs to global markets:

- Challenge: Scaling from bench-scale production to industrial quantities is no small feat. It requires significant capital investment, infrastructure, and expertise.

- Solution: Collaborative efforts between academia, industry, and governments can bridge the gap. Public-private partnerships, investment in research and development, and policy incentives can play pivotal roles.

Material Properties

Meeting diverse market needs:

- Challenge: While PHA offers a range of properties, it doesn’t always directly match the performance characteristics of some widely used plastics.

- Solution: Blending PHAs with other biopolymers or additives, refining the production process, or creating composites can help fine-tune material properties to meet specific application requirements.

Market Awareness and Acceptance

Changing perceptions and habits:

- Challenge: Despite its benefits, many consumers and industries remain unaware of PHA or are hesitant to switch from tried-and-true materials.

- Solution: Education campaigns, transparent labeling, and showcasing successful PHA applications can shift public perception. Collaborations with influential brands can also drive market acceptance.

End-of-Life Management

Ensuring the promise of biodegradability:

- Challenge: While PHA is biodegradable, its decomposition rate can vary based on environmental conditions. There’s also a risk of littering behavior if people assume it will quickly degrade anywhere.

- Solution: Public education about proper disposal is key. Additionally, developing composting infrastructure and standards for biodegradable materials can ensure that PHA products are effectively broken down post-use.

Broader Implications of Embracing PHA

As with any transformative shift, the transition to PHA brings about far-reaching impacts that extend beyond mere material substitution. These implications span environmental, economic, and social domains, shaping a new paradigm for how we interact with materials in our daily lives.

Environmental Impacts

- Reduced Fossil Fuel Dependency: Shifting away from petrochemical-derived plastics means less reliance on fossil fuels, with all their associated environmental costs, from extraction to transportation.

- Lower Carbon Footprint: Producing PHA, especially when using waste streams or carbon sequestration methods, can result in a much lower carbon footprint compared to traditional plastics.

- Mitigation of Plastic Pollution: The inherent biodegradability of PHA means fewer plastic fragments persisting in our oceans, rivers, and landscapes. This has positive cascading effects on ecosystems and wildlife.

Economic Implications

- Creation of Green Jobs: As the PHA industry grows, so will the demand for jobs in biotechnology, agriculture (for feedstocks), and PHA product manufacturing and design.

- Market Dynamics: As consumers become more environmentally conscious, brands that adopt biodegradable packaging or products may gain a competitive edge. This could reshape market leaders and brand loyalties.

- Stimulus for Research and Innovation: The challenges and potentials of PHA can lead to increased funding in research and development, driving scientific and technological advancements.

Social and Cultural Shifts

- Redefining ‘Disposability’: With PHA, items once seen as “throwaway” can now be viewed through the lens of a circular economy, reshaping societal values around consumption and waste.

- Awareness and Education: The story of PHA—how it’s derived, its benefits, and its end-of-life—can serve as an educational tool, raising awareness about sustainable choices and their impacts.

- Potential for Localized Production: Given the diverse feedstock options and the potential for small-scale PHA production, communities around the world might harness local resources to produce their own bioplastics, fostering self-sufficiency and reducing the environmental costs of transportation.

Conclusion

As we stand at the crossroads of environmental challenges and technological innovation, PHA emerges as a beacon of hope in the realm of sustainable materials. But it’s more than just a biodegradable plastic—it’s a symbol of the paradigm shift humanity is poised to make.

From its microbial origins to its vast application potential, PHA encapsulates the ethos of a world where we don’t have to compromise modern conveniences for the sake of the environment. Its adoption could lead us to a circular economy where waste is a relic of the past and sustainability is embedded in our daily lives.

Yet, as with any transformative journey, challenges lie ahead. It’s not just about producing a biopolymer; it’s about changing mindsets, reshaping industries, and fostering collaborations across sectors and borders. It requires consumers demanding change, industries taking bold steps, and policymakers providing the necessary frameworks.

In the end, the story of PHA is not one of mere material science. It’s a narrative of hope, innovation, and collective action. As we transition towards a world less dependent on traditional plastics, we are not only finding solutions to pressing environmental issues but also redefining our relationship with the planet.