Introduction

Phenolic Resin, a quietly influential material in the world of injection molding, holds the power to shape products across diverse industries. Whether you’re in automotive, electronics, or kitchenware, understanding the distinct properties and applications of Phenolic Resin can greatly enhance your manufacturing process.

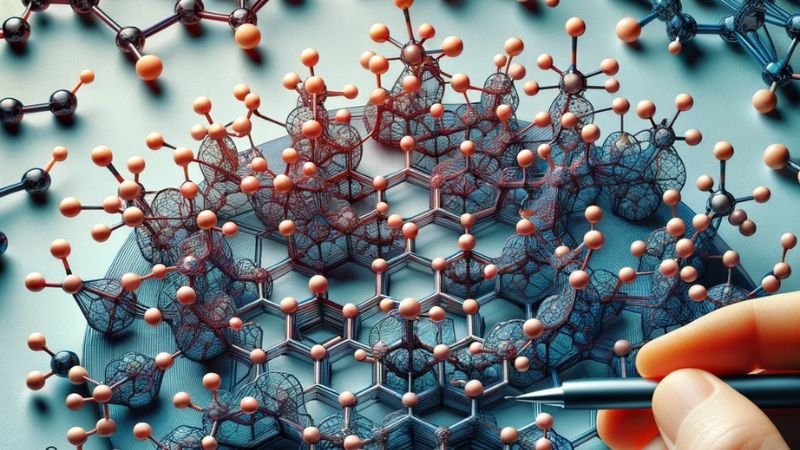

What is Phenolic Resin?

Phenolic Resin, often referred to as “Phenolic,” is a versatile synthetic polymer known for its exceptional heat resistance and mechanical strength. It is crafted through the fusion of phenol and formaldehyde under controlled conditions, resulting in a polymer that has played a fundamental role in the plastics industry for decades.

The Properties of Phenolic Resin

Phenolic Resin offers a range of properties that make it an excellent choice for injection molding:

- Heat Resistance: Phenolic Resin can endure high temperatures without losing its shape or structural integrity, making it vital for applications exposed to heat or fire.

- Mechanical Strength: Its robust mechanical strength is well-suited for parts facing heavy loads and wear.

- Electrical Insulation: Phenolic Resin excels as an electrical insulator, a crucial characteristic for electronic components and electrical insulation.

| Property | Value |

|---|---|

| Melting Point | 160-220°C |

| Density | 1.2-1.4 g/cm³ |

| Tensile Strength | 60-80 MPa |

| Heat Deflection Temp. | 150-200°C |

| Dielectric Strength | 12-20 kV/mm |

These properties make Phenolic Resin a valuable resource in the world of injection molding, delivering reliability and longevity.

Applications in Injection Molding

The versatility of Phenolic Resin finds expression in a wide range of industries, making it a preferred choice for injection molding. Let’s take a closer look at how Phenolic Resin shines in various sectors:

1. Automotive Industry

In the automotive sector, Phenolic Resin is indispensable for crafting components that can withstand high temperatures and mechanical stress. Brake pads, clutch discs, and electrical connectors all benefit from Phenolic Resin’s reliability.

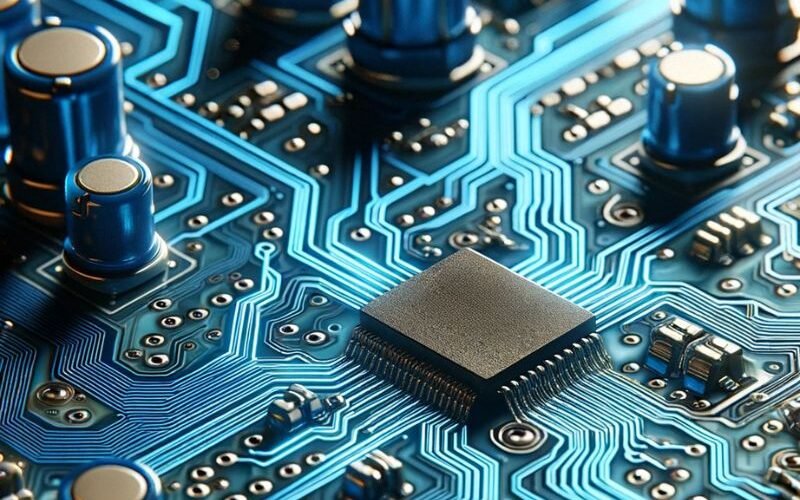

2. Electronics and Electrical Components

Phenolic Resin’s exceptional electrical insulation properties are invaluable in electronic components. It’s commonly found in circuit boards, switches, sockets, and insulators, safeguarding delicate electronics from electrical interference.

3. Kitchenware and Appliances

Phenolic Resin provides the durability and heat resistance required for kitchenware and appliance handles and knobs, ensuring longevity and safety even under everyday use and high temperatures.

4. Industrial Machinery

Manufacturers of industrial machinery turn to Phenolic Resin for components that need to endure harsh conditions. Gears, bushings, and insulating materials benefit from its reliability.

5. Aerospace and Defense

In aerospace and defense, Phenolic Resin is trusted for parts that demand both strength and resistance to extreme temperatures, contributing to safety and functionality in aircraft and defense systems.

6. Consumer Goods

Phenolic Resin enhances the durability and usability of a wide array of consumer goods, from tool handles to power tool shells, providing a cost-effective choice for enduring products.

The Advantages of Using Phenolic Resin

Phenolic Resin offers a host of advantages, making it a smart choice for injection molding:

1. Cost-Effectiveness

Phenolic Resin strikes a balance between performance and affordability, making it an appealing choice for businesses looking to optimize manufacturing processes without sacrificing quality.

2. Durability

Phenolic Resin excels in creating long-lasting components. Its resistance to wear and heat ensures reliable performance even under demanding conditions.

3. Chemical Resistance

Phenolic Resin’s resistance to a wide range of chemicals is vital in industries exposed to corrosive substances, such as the chemical and petrochemical sectors.

4. Dimensional Stability

Products made from Phenolic Resin maintain their shape and dimensions over time, crucial for precision components and those exposed to varying temperatures.

5. Low Shrinkage

Phenolic Resin experiences minimal shrinkage during injection molding, ensuring the final product closely matches the intended design.

6. Electrical Insulation

Its excellent electrical insulation properties make it a top choice for applications where preventing electrical leakage is essential.

7. Flame Resistance

Phenolic Resin is inherently flame-resistant, meeting stringent fire safety standards.

Challenges and Considerations

While Phenolic Resin offers numerous advantages, it’s essential to be aware of the challenges and considerations that come with using this material in injection molding:

Molding Temperature

Phenolic Resin typically requires higher molding temperatures compared to some other plastics, necessitating suitable equipment and temperature control.

Tooling Requirements

Its abrasiveness can lead to increased wear on molds and tooling, demanding regular maintenance and appropriate coatings to prolong mold life.

Odor and Emissions

During molding, Phenolic Resin may emit odors and gases, requiring proper ventilation and air filtration in enclosed spaces.

Handling Precautions

Phenolic Resin can irritate the skin and eyes, necessitating proper handling precautions and protective equipment for worker safety.

Post-Molding Operations

Some products made from Phenolic Resin may require additional post-molding operations, such as machining or finishing, to achieve desired surface quality and precision.

Material Selection

Choosing the right grade and formulation of Phenolic Resin is critical to meet specific application requirements, often requiring collaboration with experts.

Environmental Impact

In an era where environmental concerns loom large, the environmental impact of Phenolic Resin deserves consideration:

Recycling Possibilities

Phenolic Resin, a thermosetting plastic, faces recycling challenges. Nevertheless, efforts are underway to develop recycling techniques for Phenolic Resin materials, reducing waste.

Eco-Friendly Alternatives

While Phenolic Resin offers advantages, some industries explore eco-friendly alternatives, including bio-based resins and recyclable thermoplastics, aligning with sustainability goals.

Compliance with Regulations

Adherence to environmental regulations and certifications related to Phenolic Resin is essential to meet standards and environmental obligations in your region.

Conclusion

Phenolic Resin is a testament to the adaptability and endurance of synthetic polymers in injection molding. Its widespread applications, cost-effectiveness, and exceptional properties establish it as a valuable choice for manufacturers spanning various sectors.

Comprehending the advantages and considerations when working with Phenolic Resin empowers businesses to harness its potential effectively. As the industry embraces sustainability, Phenolic Resin continues to play a pivotal role in shaping a more environmentally conscious future.

We trust this article has illuminated the realm of Phenolic Resin and its impact on injection molding. For further exploration of its applications or any questions, please don’t hesitate to reach out. Your journey into the world of plastics continues, with Phenolic Resin as your steadfast companion.

Stay tuned for more insights into the realm of injection molding and plastic manufacturing on our website.