Introduction

Imagine the clear plastic bottle that holds your favorite beverage, the vibrant polyester clothing you wear, or even the durable fibers used in automotive components. Chances are, PET is intimately involved in the creation of these everyday items. But what exactly is PET, and why is it so crucial in the world of plastics?

Section 1: Understanding Polyethylene Terephthalate

Polyethylene Terephthalate, or PET, is a versatile and widely used thermoplastic polymer that has left an indelible mark on various industries and aspects of our lives. To truly appreciate its significance, let’s dive deeper into what PET is and what makes it a material of choice for a multitude of applications.

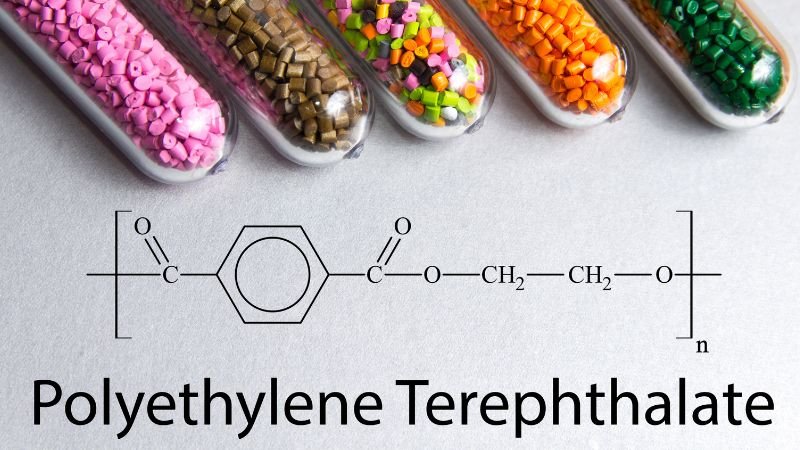

1.1 The Chemistry of PET

At its core, PET is a synthetic polymer composed of repeating units of two monomers: ethylene glycol and terephthalic acid. This chemical structure is responsible for many of PET’s remarkable properties. It forms a long-chain polymer with a high degree of crystallinity, contributing to its strength and durability. The combination of oxygen, carbon, and hydrogen atoms in PET’s molecular makeup gives it its lightweight and transparent nature, making it ideal for a variety of applications.

1.2 A Brief History of PET

The history of PET traces back to the mid-20th century when it was first synthesized and patented in the United Kingdom by Whinfield and Dickson in 1941. Initially, PET was developed as a textile fiber known as “Terylene” or “Dacron,” gaining popularity for its resistance to wrinkles and ease of care. Over time, PET’s applications expanded well beyond textiles, solidifying its role as a versatile plastic.

1.3 PET: A Material for Modern Life

What sets PET apart is its adaptability and wide range of applications. It has become an essential material in various industries, including:

- Packaging: PET’s clarity, barrier properties, and lightweight nature make it an ideal choice for beverage bottles, food containers, and blister packaging.

- Textiles: As a polyester fiber, PET is used to create clothing, carpets, and upholstery due to its durability, wrinkle resistance, and color-fastness.

- Automotive: PET is found in car interiors, seat fabrics, and under-the-hood components, where its strength and heat resistance shine.

- Electronics: PET films are used in electronic displays, capacitors, and insulating materials.

- Medical: PET is used in medical devices, such as IV bags and tubing, due to its biocompatibility and ease of sterilization.

Section 2: Properties of PET

Polyethylene Terephthalate (PET) is a remarkable plastic with a rich set of properties that make it an invaluable material in various applications.

2.1 Strength and Durability

PET boasts excellent tensile strength, making it one of the stronger thermoplastics. This means it can withstand significant mechanical stresses without deforming or breaking. Whether used in beverage bottles or automotive components, PET’s strength ensures the longevity of products.

2.2 Transparency and Clarity

One of PET’s most visually striking attributes is its transparency. PET is exceptionally clear, allowing consumers to see the contents of a bottle or the vibrant colors of PET-based packaging. This property is essential for products like water and soft drink bottles, where the visual appeal of the contents is crucial.

2.3 Lightweight Nature

PET is a lightweight material, which is particularly advantageous in the packaging industry. Its low density not only reduces shipping costs but also contributes to a lower carbon footprint. PET’s lightweight nature plays a pivotal role in reducing energy consumption during transportation.

2.4 Barrier Properties

In packaging applications, PET’s barrier properties shine. It effectively prevents the permeation of oxygen, carbon dioxide, and moisture, safeguarding the freshness and shelf life of food and beverages.

2.5 Recyclability

Perhaps one of PET’s most celebrated features is its recyclability. PET is highly recyclable, and recycled PET (rPET) is used to create new products, reducing environmental impact and promoting a circular economy.

Section 3: Production Process

The journey of Polyethylene Terephthalate (PET) from raw materials to the versatile material we know is a testament to precision engineering and chemical synthesis. In this section, we’ll delve into the intricacies of the PET production process.

3.1 Polymerization: Creating PET Resin

The production of PET begins with a process called polymerization. This chemical reaction involves the combination of its two main components: ethylene glycol and terephthalic acid. The result is a clear and viscous liquid known as bis(2-hydroxyethyl) terephthalate, or BHET. Alternatively, PET resin can also be synthesized directly using dimethyl terephthalate (DMT) and ethylene glycol.

The polymerization process typically involves these steps:

- Esterification: Terephthalic acid and ethylene glycol combine in a reactor, resulting in BHET.

- Polycondensation: Further heating and vacuum conditions remove excess ethylene glycol, creating high molecular weight PET.

3.2 Melt Processing: Transforming Resin into Products

PET resin, in the form of small pellets or granules, is transformed into various products through melt processing. Key methods include:

- Injection Molding: Melting PET resin pellets and injecting the molten material into molds creates a wide range of products, from bottle caps to intricate automotive components.

- Extrusion: PET resin is melted and forced through a die to create continuous shapes such as plastic films, sheets, and profiles.

- Blow Molding: For hollow objects like bottles, PET is melted and blown into a mold to take its desired shape.

3.3 Quality Control in PET Production

Quality control is paramount in PET production to ensure the material meets strict specifications for different applications. Key aspects include:

- Viscosity Control: Precisely controlling PET’s viscosity achieves desired properties in the final product.

- Contaminant Detection: Detecting and removing impurities or contaminants in the resin ensures product quality.

- Consistent Processing: Maintaining uniform processing conditions is crucial for producing PET with consistent properties.

- Recycling and Sustainability: Incorporating recycled PET (rPET) into production reduces environmental impact.

Advancements in production technology and research continually refine the PET production process, making it more efficient and environmentally friendly.

Section 4: Applications of PET

Polyethylene Terephthalate (PET) stands as a testament to the ingenuity of material science. Its exceptional properties have led to diverse applications across various industries. In this section, we’ll embark on a journey through some of the most prominent uses of PET.

4.1 Packaging Innovations

PET’s remarkable combination of clarity, strength, and barrier properties has revolutionized the packaging industry. It is the material of choice for countless products, including:

- Beverage Bottles: PET’s transparency showcases contents and its strength prevents breakage, making it ideal for water, soda, and juice bottles.

- Food Containers: PET containers are used for a wide range of food products, preserving freshness and safety.

- Blister Packaging: In pharmaceuticals, PET is used for blister packaging, ensuring product integrity and tamper resistance.

4.2 Textiles and Apparel

In the textile industry, PET transforms into polyester fibers, used to create clothing and textiles. Advantages include:

- Durability: PET-based fabrics are known for their durability, suitable for sportswear, outdoor gear, and car upholstery.

- Wrinkle Resistance: PET fibers are naturally wrinkle-resistant, reducing the need for ironing or special care.

- Color Fastness: PET retains vibrant colors, even after multiple washes, ensuring long-lasting apparel.

4.3 Automotive Advancements

PET’s lightweight and durable properties lead to innovative applications:

- Interior Components: PET-based materials are used in dashboard covers, seat fabrics, and carpeting, contributing to weight reduction and improved fuel efficiency.

- Under-the-Hood: PET is employed for engine covers, cooling system components, and battery casings due to its heat resistance and mechanical strength.

4.4 Electronics and Packaging

The electronics industry benefits from PET’s electrical insulation properties, using it for various applications:

- Cable Insulation: PET insulates electrical cables and wires, enhancing safety.

- Displays: PET films are used in LCD and OLED displays due to their transparency and heat resistance.

4.5 Medical and Healthcare

In the healthcare sector, PET plays a crucial role:

- Medical Devices: PET’s biocompatibility and ease of sterilization make it a preferred choice for IV bags, tubing, and prosthetic implants.

- Pharmaceutical Packaging: PET is used for pharmaceutical packaging, ensuring product integrity and safety.

4.6 Sustainable Initiatives

Growing concerns about environmental sustainability drive increased use of recycled PET (rPET) in various applications, reducing PET production’s environmental footprint.

Section 5: Sustainability and PET

As our world grapples with environmental concerns, the sustainability of materials like Polyethylene Terephthalate (PET) comes into sharp focus. In this section, we’ll examine PET’s environmental impact, its recyclability, and the innovative practices that are helping reduce its footprint on the planet.

5.1 PET’s Environmental Impact

While PET offers numerous advantages, its production does have environmental implications, including:

- Resource Consumption: Producing PET resin requires significant energy and raw materials, notably crude oil for the ethylene glycol component.

- Plastic Waste: Improper disposal of PET products can contribute to plastic waste, which can persist in the environment for hundreds of years.

5.2 Recycling PET: A Sustainable Solution

PET’s redeeming feature is its recyclability. PET is one of the most recycled plastics globally, thanks to its purity, clarity, and ease of processing. The recycling process involves several key steps:

- Collection: PET products, such as bottles and containers, are collected from various sources, including households, businesses, and recycling centers.

- Sorting: Recycling facilities use automated systems to sort PET from other plastics and materials.

- Cleaning: Thorough cleaning removes labels, caps, and contaminants from collected PET items.

- Shredding: The cleaned PET is shredded into small pieces or flakes.

- Melting and Reforming: These flakes are melted and reformed into new PET products, including bottles, clothing, and even carpet fibers.

Recycled PET, often referred to as rPET, conserves energy, reduces resource consumption, and minimizes the volume of plastic waste. The use of rPET has become increasingly common in various industries, promoting a more sustainable and circular economy.

5.3 Sustainable PET Initiatives

In response to growing environmental concerns, industries are actively seeking sustainable alternatives and practices:

- Bio-Based PET: Researchers explore the use of bio-based feedstocks, such as plant-derived ethylene glycol, to reduce reliance on fossil fuels in PET production.

- Eco-Friendly Packaging: Companies invest in eco-friendly packaging designs, such as lightweighting bottles to reduce material use and carbon emissions during transportation.

- Public Awareness: Educating consumers about the importance of recycling and responsible disposal is a critical aspect of sustainable PET initiatives.

- Extended Producer Responsibility (EPR): Some regions implement EPR programs, holding manufacturers responsible for the recycling and proper disposal of PET products.

5.4 The Path to a Sustainable Future

Polyethylene Terephthalate has shown its adaptability, not only as a versatile material but also as a champion in the quest for sustainability. As technologies and practices continue to evolve, PET plays a pivotal role in reducing its environmental footprint.

Section 6: PET vs. Other Plastics

In the vast landscape of polymers and plastics, each material has its own set of characteristics and applications. In this section, we’ll compare Polyethylene Terephthalate (PET) to some of its fellow plastics, highlighting the strengths and distinctions that set PET apart.

6.1 PET vs. Polypropylene (PP)

Polypropylene is another widely used thermoplastic, often in competition with PET:

- Clarity vs. Flexibility: PET boasts superior clarity compared to PP, making it preferred for products where transparency is essential, such as beverage bottles. PP, on the other hand, is known for its flexibility and resistance to chemicals, making it suitable for containers that need to withstand harsh contents.

- Recyclability: Both PET and PP are recyclable, but PET’s clarity and compatibility with recycling processes have given it an edge in recycling rates.

6.2 PET vs. Polyethylene (PE)

Polyethylene is one of the most common plastics, and it comes in various forms:

- Strength and Rigidity: PET is stronger and more rigid than most forms of polyethylene, making it suitable for applications requiring durability, like automotive components and medical devices.

- Transparency: While some forms of polyethylene are transparent, PET offers consistent clarity across a broader range of products.

6.3 PET vs. Polyvinyl Chloride (PVC)

Polyvinyl Chloride is known for its versatility and durability:

- Chemical Resistance: PVC surpasses PET in chemical resistance, making it preferred for pipes, wire insulation, and other applications where exposure to harsh chemicals is a concern.

- Recyclability and Sustainability: PET is often viewed as a more sustainable option due to its higher recycling rates and compatibility with eco-friendly practices.

6.4 PET vs. Polystyrene (PS)

Polystyrene is recognized for its insulation properties and versatility:

- Insulation: Polystyrene excels in thermal insulation, making it a preferred choice for disposable coffee cups and food containers designed to retain heat.

- Environmental Concerns: Polystyrene has faced criticism for its environmental impact, especially in its non-recyclable forms. PET’s recyclability and growing use of rPET contribute to its more favorable sustainability profile.

While each plastic has its unique strengths, PET’s combination of transparency, strength, recyclability, and versatility has made it a standout choice for a wide range of applications. Its adaptability across industries is a testament to its enduring significance in the world of polymers.

Section 7: Future Prospects of PET

Polyethylene Terephthalate (PET) has come a long way from its early days, continually evolving to meet the ever-changing demands of modern industries. As we look ahead, it’s exciting to consider the innovations and trends that are shaping the future of PET.

7.1 Sustainable PET

Sustainability remains at the forefront of the plastics industry, and PET is no exception. In the coming years, we can expect to see:

- Increased Recycling: A growing focus on recycling and circular economy practices will continue to boost the use of recycled PET (rPET) in various applications, further reducing PET’s environmental impact.

- Bio-Based PET: Researchers are actively exploring bio-based feedstocks for PET production, aiming to reduce the reliance on fossil fuels and lessen the carbon footprint.

7.2 Advanced Manufacturing Techniques

Manufacturing processes for PET are becoming more sophisticated and efficient:

- 3D Printing: PET is finding its way into 3D printing, enabling the creation of intricate and custom-designed objects, from prototypes to medical implants.

- Nanotechnology: Nanomaterials are being incorporated into PET to enhance its properties, such as improving barrier performance in food packaging.

7.3 Enhanced Functionalities

Innovation is driving the development of PET with enhanced functionalities:

- Smart Packaging: PET is being integrated with smart technology to create packaging that can monitor freshness, track inventory, and even communicate with consumers.

- Biodegradable PET: Research into biodegradable PET variants is ongoing, offering a more sustainable solution for single-use items.

7.4 Lightweighting and Design

Efforts to reduce material use while maintaining performance will continue:

- Automotive Lightweighting: The automotive industry will increasingly turn to PET and other lightweight materials to improve fuel efficiency and reduce emissions.

- Packaging Design: PET packaging will evolve to be more efficient in terms of material use, ensuring products are well-protected while minimizing waste.

7.5 Expansion into New Markets

PET will explore uncharted territories:

- Healthcare: PET’s biocompatibility and ease of sterilization will lead to new applications in medical devices and surgical instruments.

- Aerospace: The lightweight and durable nature of PET make it a candidate for aerospace components, especially as the industry embraces sustainable materials.

The future of Polyethylene Terephthalate is rife with possibilities. With ongoing research, technological advancements, and an unwavering commitment to sustainability, PET is poised to continue its journey as a versatile, adaptable, and eco-conscious material.

Section 8: Conclusion

In closing, Polyethylene Terephthalate is not just a plastic, it’s a symbol of human ingenuity and adaptability. Its journey from conception to its role in the materials landscape today is a testament to human innovation and the pursuit of a more sustainable future. As we continue to explore the ever-expanding potential of PET, we find inspiration in its ability to evolve and adapt, shaping a world where materials meet both human needs and environmental stewardship.

Section 9: References

In crafting this comprehensive exploration of Polyethylene Terephthalate (PET), we’ve drawn from a wealth of knowledge and research. Here are the references and sources that have informed our journey:

- Gibson, I. (2015). Polyesters. In The Biomedical Engineering Handbook (4th ed., pp. 1573-1588). CRC Press.

- PlasticsEurope. (2021). Plastics – the Facts 2021. [PDF]. Plastics Europe Facts 2021

- Jansson, Å. (2019). Polyethylene Terephthalate (PET) Bottles as a Resource in the Circular Economy. [Doctoral dissertation, Chalmers University of Technology]. Chalmers Research: Polyethylene Terephthalate (PET) Bottles as a Resource in the Circular Economy

- Raquez, J. M., Habibi, Y., Murariu, M., & Dubois, P. (2013). Polylactide (PLA): Synthesis, Properties, and Applications. In Green Polymer Chemistry: Biocatalysis and Materials II (pp. 1-68). American Chemical Society.

- Harper, C. A. (2002). Handbook of Plastic Processes. John Wiley & Sons.

- Raju, R. M. (2016). Polymer Science and Technology: Plastics, Rubber, Blends, and Composites. CRC Press.

- Ghosh, S. K. (2015). Polymer Composites, Volume 2: Nanocomposites. CRC Press.

- European PET Bottle Platform (EPBP). (2021). PET is Fully Recyclable. EPBP: PET is Fully Recyclable

- PlasticsEurope. (2020). Circular Economy for Plastics. [PDF]. PlasticsEurope: Circular Economy for Plastics

- United States Environmental Protection Agency. (2021). Sustainable Materials Management (SMM) Sustainable Materials Management. EPA Sustainable Materials Management (SMM)