Introduction

Epoxy Resin, known for its strength and versatility, pairs seamlessly with the injection molding process. When combined, a robust, durable plastic material is created, ideal for a vast range of industrial applications. This union not only ensures the production of high-quality, resilient products but also meets the precision and consistency demands across various sectors. Through the following sections, we’ll explore the intriguing journey of epoxy resin, its interaction with injection molding, and the remarkable benefits this synergy brings to the modern manufacturing landscape.

Historical Usage of Epoxy Resin

The roots of epoxy resin trace back to the 1930s, with notable utilization blossoming in the 1940s for dental prosthetics due to its safe interaction with human tissues. Its journey escalated across sectors like aviation, automotive, and construction, given its excellent adhesive properties and corrosion resistance. A significant leap was its application in aerospace for crafting lightweight yet robust aircraft components. Over the decades, epoxy resin’s versatility has continually expanded, finding its place in myriad applications, setting a solid foundation for its alliance with injection molding technology.

The Chemistry Behind Epoxy Resin

Epoxy resin is famed for its formidable properties, and the credit largely goes to its unique chemical structure. At the heart of epoxy resin is a thermosetting polymer, distinguished by its cross-linked molecular chains. Here’s a simplistic delve into the chemistry that empowers epoxy resin.

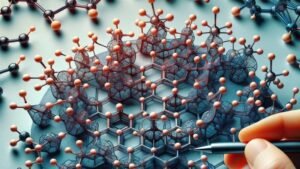

Molecular Structure

Epoxy resin comprises molecules with an epoxide group, a reactive ring-shaped structure. The presence of this epoxide group is pivotal as it enables the resin to react with various curing agents or hardeners, facilitating a cross-linking process that is the cornerstone of epoxy resin’s robustness.

The Cross-linking Process

When epoxy resin interacts with a hardener, a chemical reaction ensues, leading to the formation of covalent bonds between the molecular chains of both compounds. This cross-linking process transforms the liquid epoxy resin and hardener mixture into a solid, inflexible material. The resultant cross-linked network endows epoxy resin with its characteristic strength, rigidity, and resistance to environmental factors.

Tunable Properties

A notable aspect of epoxy resin’s chemistry is its tunability. By varying the types and proportions of resins and hardeners, or by introducing additives, the mechanical and thermal properties of the resultant material can be fine-tuned. This versatility opens up a wide range of possibilities, making epoxy resin adaptable to specific needs across different applications.

Epoxy Resin in Injection Molding

The rendezvous of epoxy resin with injection molding heralds a union of strength and precision, a meld that’s conducive to creating highly durable and accurate components. This section unfolds the process of integrating epoxy resin into injection molding and the resultant boons.

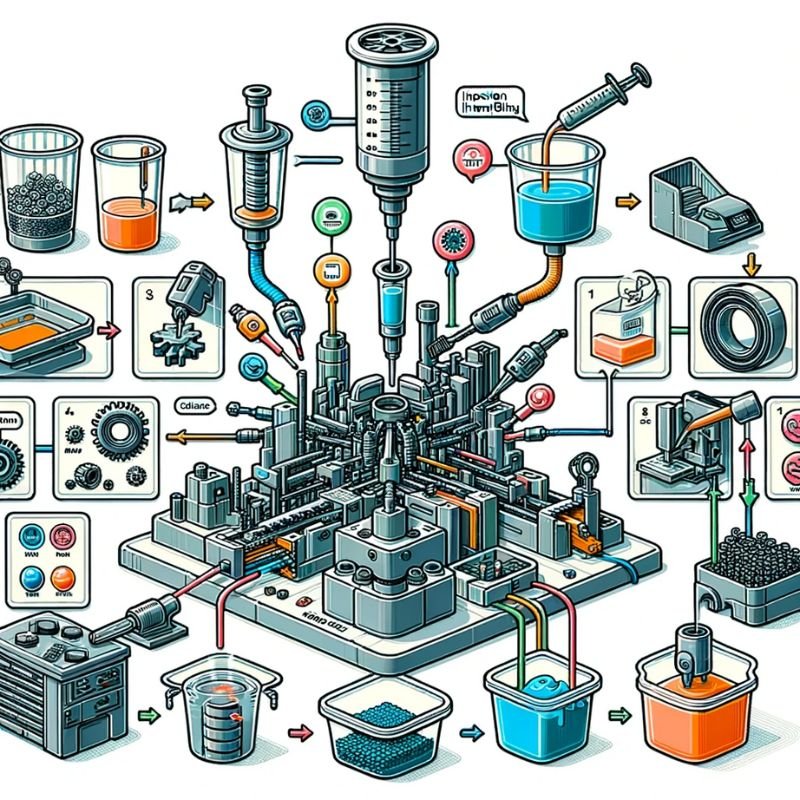

The Process

In a typical injection molding cycle, epoxy resin, alongside its hardener, is fed into a heated barrel where it attains a molten state. This mixture is then injected into a mold cavity under high pressure. As the concoction settles within the mold, it commences the curing process, evolving from a liquid to a solid state as the cross-linking reaction progresses. Once fully cured, the mold is opened, and the finished part is ejected, ready to embark on its journey of utility.

Benefits Unveiled

Epoxy resin’s tryst with injection molding isn’t merely a process; it’s a gateway to a realm of benefits:

- Enhanced Durability: The cross-linking chemistry of epoxy resin gifts the molded products with superior durability. They stand resilient against wear, corrosion, and environmental adversities, ensuring a prolonged lifespan even in challenging conditions.

- High Performance: The precision inherent in injection molding, coupled with epoxy resin’s strength, yields products that exude high performance. Their ability to maintain integrity under stress makes them suitable for critical applications.

- Cost-Efficiency: While the upfront costs may seem substantial, the long-term cost efficiency is noteworthy. The longevity and low maintenance requirements of epoxy resin molded products offset initial investments, rendering it a cost-effective choice in the long run.

- Design Flexibility: The adaptability of epoxy resin’s properties and the precision of injection molding offer a wide design latitude. This flexibility is pivotal for catering to the diverse needs of different industries, from automotive to electronics.

Applications of Molded Epoxy Resin Products

The fusion of epoxy resin with injection molding has paved the way for a myriad of applications across diverse sectors. This section illuminates the extensive array of products borne from this alliance, and the industries they significantly impact.

| Industry | Application Examples |

|---|---|

| Industrial | Gears, bearings, structural components |

| Electronics | Encapsulation and protection of electronic components |

| Automotive | Casings, housings, structural parts |

| Construction | Bonding and anchoring structural elements |

| Aerospace | Lightweight yet sturdy parts construction |

| Food & Beverage | Durable containers and utensils |

| Marine | Structural components, protective coatings |

Advancements in Epoxy Resin Technology

The trajectory of epoxy resin technology is one of constant evolution, particularly in its alliance with injection molding. This section outlines recent advancements that are enhancing epoxy resin’s compatibility with injection molding, leading to superior products.

Enhanced Formulations

Recent years have seen the development of advanced epoxy resin formulations aimed at improving processing ease and final product properties. These formulations are tailored to meet specific demands such as improved flow, reduced cure time, and enhanced thermal or mechanical properties.

Nanotechnology

The integration of nanotechnology with epoxy resin is a significant leap forward. By incorporating nanoparticles, the mechanical, thermal, and barrier properties of molded epoxy resin products are significantly enhanced without compromising the inherent advantages of epoxy resin.

Additive Manufacturing

The cross-pollination of epoxy resin technology with additive manufacturing or 3D printing is opening new avenues. This synergy is enabling the production of complex, high-precision molds for injection molding, reducing lead times, and allowing for more intricate design capabilities.

Sustainable Epoxy Resins

In a bid to align with global sustainability goals, the development of bio-based epoxy resins is gaining momentum. These resins are derived from renewable resources, marking a step towards reducing the carbon footprint of epoxy resin production and application.

Smart Epoxy Resins

The inception of smart epoxy resins capable of self-healing or changing properties in response to environmental stimuli is a remarkable advancement. These innovative resins hold the promise of extending the lifespan and functionality of molded products.

Advanced Curing Technologies

Novel curing technologies are emerging to expedite the curing process of epoxy resin in injection molding applications. These advancements are pivotal in enhancing production efficiency and product quality.

Sustainability Aspect

In a world increasingly veering towards sustainable practices, the epoxy resin and injection molding nexus isn’t lagging. This section sheds light on the environmental implications and the strides towards sustainability within this realm.

| Aspect | Description |

|---|---|

| Environmental Impact | Traditional epoxy resins derived from petrochemicals pose disposal challenges. |

| Bio-based Epoxy Resins | Epoxy resins derived from renewable resources reducing environmental impact. |

| Recycling Innovations | Chemical recycling techniques improving epoxy resin product recyclability. |

| Energy Efficiency in Production | Energy-efficient practices in injection molding reducing energy consumption. |

| Waste Reduction | Minimal material wastage in injection molding contributing to sustainability. |

| Eco-friendly Additives | Incorporation of eco-friendly additives aligning with environmental considerations. |

Conclusion

The collaboration between epoxy resin and injection molding has paved the way for durable, high-performance products across numerous sectors. From its historical origins to modern-day applications and forward-thinking sustainability practices, this synergy demonstrates a remarkable journey of innovation. As technology advances, the alliance of epoxy resin and injection molding continues to promise a future of enhanced manufacturing, pushing the boundaries in material science while echoing a strong commitment to environmental sustainability.