Isingeniso

Ukwenza kahle ukwenziwa kokujova okubumbayo kubalulekile ukukhiqiza, ukufuna inhlanganisela yobuchwepheshe nobungcweti. Kubalulekile emikhiqizweni emincane, eyinkimbinkimbi, lapho yonke imininingwane ithembele ekubumbeni okuhlekisayo nokukhiqiza. Ukubumba okunembile kuqinisekisa ikhwalithi eguqukayo, ikakhulukazi e-Aerospace, ezokwelashwa kanye ne-elekthronikhi, lapho ngisho namaphutha amancane angaholela khona ezindabeni ezibalulekile.

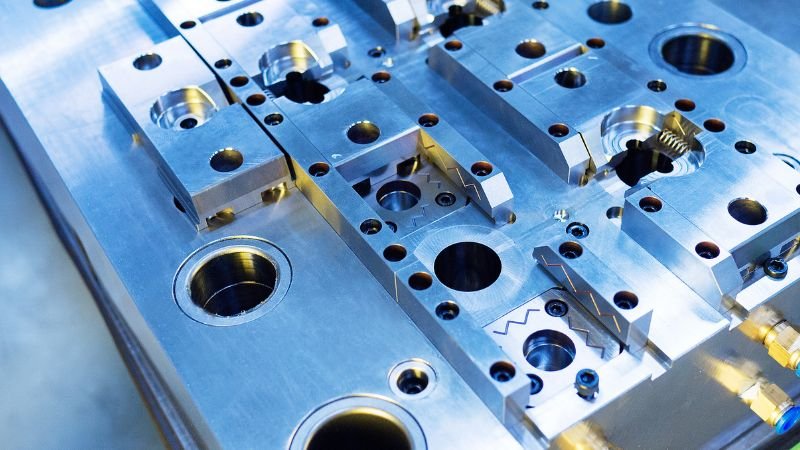

Kuyini ukuqondiswa ngokunemba kokwenza lokhu?

I-Precision Umjovo Lokwenza Ukuhlanganisa ihlanganisa i-metallurgy, mechanics, kanye nobungcweti obuqine ukudala isikhunta esinembile esisetshenziselwa ukukhiqiza izingxenye ngokubumba komjovo. Ngokungafani nokubumba njalo okugxile ekukhiqizeni inqwaba, isikhunta esinembile sibeka ukunemba nokunaka imininingwane. Baqakathekile izimboni zezikhuphu eziphezulu lapho ukunemba kubalulekile.

Ukucacisa ukucacisa

Ukunemba, ngokwesimo sokwenza isikhunta, kudlula ukunemba nje. Inika amandla amandla okubumba:

- Phindaphinda: Ngokwethembeka sibonisa ukwakheka kwangempela kuyo yonke ingxenye ekhiqizwayo.

- Sekela: Gcina imininingwane eminingi yokukhiqiza imijikelezo.

- Liqukethe: Qinisekisa ukuthi yonke ingxenye ekhiqizwayo ayinakuphikwa kontanga yayo ngobukhulu kanye nekhwalithi.

Uhluke ngokuphelele ekulweni okujwayelekile kwesikhunta

Ngokuqhathaniswa, isikhunta esinembile kanye nezikhunta ezijwayelekile zihluke kakhulu ezindaweni ezilandelayo:

- Ukubekezelela: Ukucacisa Ukubumba kugcina ukubekezelelana okuqinile kakhulu, kwesinye isikhathi kuze kube ngama-micrometer amancane, ukuqinisekisa ukuthi izingxenye ezikhiqizwayo zingaguquguquki ngokungaguquki futhi zivumelanisa nezincazelo ze-Design.

- Inkimbinkimbi: Umthamo wokwenza imiklamo eyinkimbinkimbi, ama-geometries ahlanganisiwe, kanye nezici eziyinkimbinkimbi kuwuphawu lokunemba yokwenza.

- Ukutshalwa kwemali: Kokubili ngokwesikhathi nezinsizakusebenza, ukucacisa isikhunta kudinga ukutshala imali okukhuphukile, ukuqondanisa nekhwalithi yabo yokukhipha nokuqina.

Izimboni zincike ekubumbeni okuqondile

Medical, Aerospace, Eleospace, kanye nokuningi - Imikhakha eminingi Pivot emaphepheni isikhunta sokunemba:

- Amadivaysi ezokwelapha: Ukubumba okunembile kusho ukuthembeka kwamadivayisi wezokwelapha angenakubalwa, lapho kungafani nokungafani kwemicroscopic kungalimaza.

- Izakhi ze-Aerospace: Ukuqinisekisa ukuthi izingxenye ziyi-Lightweight kepha ziqinile futhi zinembile, ukubumba okunembile kudlala indima ebaluleke kakhulu ekwakhiweni kwe-aeroSpace.

- I-Electronics: Njengoba i-elekthronikhi miniaturize ngenkathi iba yinkimbinkimbi ngokwengeziwe, ukunemba isikhunta senza amandla okukhiqizwa kwe-compact, enemininingwane futhi ethembekile.

Izinto zokwakha ngokunemba yokwenza

Ekwenzeni ngokunemba emjovo ukwenza, izinto zokwakha zingaphezu nje kwesisekelo. Badlala indima ebalulekile, ukuxhuma ukunemba kokuqamba nokuqina, ukuqinisekisa ukuthi isikhunta singakhiqiza ngokungaguquki izingxenye eziningi ngaphandle kokulahlekelwa ukunemba noma ukugqoka.

Izici ezibalulekile zezinto zokubumba

Ukukhetha izinto ezifanele zokunemba kwenziwa inyumbana kubhekwe ngokubona nokulinganisa izakhiwo eziningi, ukuqinisekisa ukuthi isikhunta singakwazi:

- I-NORETASTER FISO: Khuthazelela izingcindezi ezinkulu zomjovo ngaphandle kwezimo zenkolo.

- Melana Nokugqoka: Gcina ubuqotho nemininingwane kuyo yonke imijikelezo engenakubalwa.

- Phatha ama-Thermal Dynamics: Lungiselela ukupholisa okusebenzayo nokubekezelela ukuhamba ngebhayisikile.

Insimbi Versus aluminium: Ukukhetha okubaliwe

Insimbi ne-aluminium kuvela njengoba abalwa bangempela ezingozini zokubumba, ngamunye ubeka izinzuzo zabo nezinkinga zabo.

Isikhunta sensimbi

Okuhle:

- Ukuvikelwa Okuphakeme Okuphakeme

- Umjikelezo wokuphila obanzi

- Amakhono amahle okuqeda indawo

USIZO:

- Izindleko Eziphakeme Zokuqala

- Izikhathi ezinde ezinde eziholayo

Isikhunta se-aluminium

Okuhle:

- Ukushesha Machine

- Ukusebenza okuhle kakhulu okushisayo

- Izindleko eziphansi

USIZO:

- Umjikelezo Wokuphila Okunomkhawulo

- Kungenzeka ukuthi ugqoke izindaba ezimweni ezinamandla aphezulu

I-Coatings nokwelashwa: Ukuthuthukisa ukusebenza kwesikhunta

Ngaphesheya kwezinto ezibonakalayo ezibonakalayo, ukumboza kanye nokwelashwa kusebenza ukukhulisa ukusebenza kwesikhunta, kwethulwa okuthuthukile:

- Gqoka ukumelana: Ukuqinisa ukuqina kokuqina kwezinto zokulwa nezinto zokwakha.

- Ukumelana nokugqwala: Ukuvikela ukumelana nokugqwala okungaba khona kusuka kumapulasitiki athile noma amasilu lokupholisa isikhunta.

- Ukukhishwa Kwezakhiwo: Ukwenza lula ukuvela okulula kwengxenye yokugcina, ukunciphisa ubungozi bezinkinga.

Ukusebenziseka kabusha kanye Nokusimama

Emhlabeni jikelele ebheke emikhubeni esimeme, ukutholwa kabusha kanye nobungane be-eco-ubungane bezinto zokwakha izidakamizwa zibukezelwe ukucatshangelwa okubucayi, okubandakanya:

- Ukusetshenziswa Kwezinto Ezibonakalayo: Ukunciphisa imfucuza ngesikhathi sokukhiqiza isikhunta.

- Ukuphela kokuvuselelwa kabusha: Ukuqinisekisa ukuthi isikhunta singasetshenziswa kabusha ukusetshenziswa kwangemva kokusebenza.

- Imikhuba ehambisanayo ye-Eco: Ukusebenzisa imisebenzi yokukhiqiza okucatshangelwa yimithelela yemvelo.

Amasu we-State-of-The-Art Machching

Ukubumba okunembile akunakuqina, zinobunjiniyela ngokucophelela, zifuna ukuvumelanisa kwamasu athuthukile machina ukuletha amasu ayinkimbinkimbi, aqondile angokoqobo.

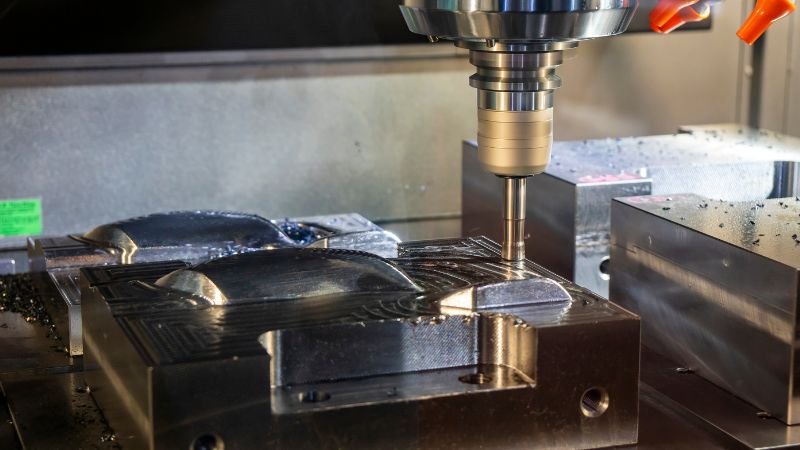

Imishini ye-CNC

I-Computer Naturalical Control (CNC) Machingining, i-LinchPIn yokubumba okunembile, ezenzakalelayo ukuguqulwa kwemiklamo yedijithali ezinhlanganweni ezingokomzimba, ukuqinisekisa:

- Ukungaguquguquki: ukuphindaphinda okusebenzayo kuyo yonke imijikelezo yokukhiqiza eminingi.

- Ukunemba: Ukunamathela ekubekezelelekeni okuqinile okuhlangene nokunemba ukwenza isikhunta.

- Ukuphathwa Kokuxazulula: Ukwenza lula ukugcwaliseka kwemiklamo eyinkimbinkimbi nama-geometries.

Ukukhishwa Kwemishini Kagesi (EDM)

Ukudonswa Kwemishini kagesi (EDM), noma ama-Spork Machching, kunika amandla abenzi bokubumba ukuba banikeze umzuzu, izici ezinemininingwane ngokunemba okuphezulu, okugxile ku:

- Imininingwane Emihle: Ukukhiqiza izici ezincane kanye nemininingwane eyinkimbinkimbi ngenye indlela oyinselele ngokusebenzisa imishini evamile.

- Ikhwalithi ephezulu: Ukunikeza ama-Perfes amahle kakhulu, kubalulekile kuzo zombili izici zobuhle nezisebenzayo zezingxenye ezibunjiwe.

- I-Hard Maching Machching: Inika amandla ama-machishini wezinto zokwakha ezilukhuni ngaphandle kokufaka ingcindezi.

I-High-Speed Maching (HSM)

Ukulinganisa ubuthana bokunemba ngokuchithwa kokukhiqizwa, okuvela ngokushesha kwemishini (HSM) njengomdlali osemqoka ku:

- Izikhathi zokuhola ezincishisiwe: khulisa ijubane lokukhiqiza ngaphandle kokuyekethisa ngokunemba.

- Qeda indawo yokuqeda:

- Ithuluzi Lide: Ukunciphisa ukugqoka kumathuluzi wemishini ngenxa yamabutho aphansi wokusika.

I-5-Axis Maching

I-5-axis machining pivots ekundleni kwayo ukuqondisa ama-axes amahlanu ahlukene ngasikhathi sinye, ukuvula:

- Ukuqaphela kweJiyometri eyinkimbinkimbi: Ukunika amandla abenzi bokubumba ukwakha amafomu ayinkimbinkimbi, ahlukahlukene.

- Ukutholakala Kwethuluzi: Ukunika amandla ukufinyelela kwezici eziyinselele zengxenye kanye nokuphakama.

- Ukusetha okukodwa-ukusetha okukodwa: Ukunciphisa izikhathi zokusetha namaphutha angenzeka ngokwenza lula imishini yokusetha okukodwa.

Ihlanganisa i-ausation

I-automation ekukhetheni kwenziwe ngokunemba akuyona into yokunethezeka kepha edingekayo, eqinisekisa:

- I-24/7 Production: Khulisa ukuphuma ngokwenza lula imijikelezo yokukhiqiza eqhubekayo, enganakekelwa.

- Iphutha lomuntu elincishisiwe: Ukusekela ukungaguquguquki nokunemba kuzo zonke izikhunta ezikhiqizwayo.

- Ukusebenziseka kahle kwezinsiza: Ukusebenzisa kahle izinto zokwakha namandla, ukuhambisana nemikhuba yokukhiqiza esimeme.

Ubunjiniyela Ukubekezelelana Okuqinile

Ukugcina ukubekezelela okuqinile ekubumbeni ngokunemba kwe-injoction inyuty kungaphezu kwezenzo ezijwayelekile zobunjiniyela, kungena endaweni lapho kulinganiselwa khona yonke imicron, phansi kwi-micron, kunganquma impumelelo noma ukwehluleka.

Ukuchazwa kokubekezelela ekubumbeni okuqondile

Ngokwesimo sokubumba okunembile, ukubekezelelana kubhekiselwa ekuhlukani okuvumelekile ezimfanelweni ezinobukhulu bengxenye eyenziwe. Ukuchazwa nokunamathela kule mikhawulo kuqinisekisa ukuthi:

- Kufanelekile: izakhi zihlangana ngaphandle komthungo emihlanganweni emikhulu.

- Umsebenzi: Izingxenye zenza kahle ngaphandle kwezithiyo zokwelapha.

- IFOMU: Ubuqotho be-aesthetic ne-ergonomic bugcinwe.

Amasu wokufeza ukubekezelela okuqinile

- Ukucacisa imininingwane: Ukusebenzisa amaqhinga wemishini ethuthukisiwe, njenge-axis-axis kanye nemishini enesivinini esiphakeme, esenza ukufeza kanye nokuvumelana kokubekezelelana okuqinile.

- Ukukhetha okuhle kwezinto ezibonakalayo: Ukukhetha izinto ezingamelana nokusetshenziswa kanzima kodwa futhi zihlala zizinzile ngokuhlukahluka ngemijikelezo ehlukahlukene ye-thermal nengcindezelo.

- Ukunemba okuvusa amathuluzi

Izinselelo Zokugcina Ukubekezelela KaMicroscopic

Ukuqinisekisa nokugcina ukubekezelelana phakathi kwama-micrometereter ambalwa kuveza izinselelo ezibulawe:

- Ukuziphatha Okubonakalayo: Ukuphatha ama-Nuances wokuthi izinsiza zikhula kanjani, inkontileka, kanye ne-warp ngaphansi kwezimo ezisebenzayo ezisebenzayo.

- Ukuqina kwemishini: Ukugcina ukuqina okungapheli nokunemba kuyo yonke imijikelezo emishini eminingi futhi ephindaphindwayo.

- Gqoka futhi uklebhule: Ukulwa nokucashunwa, kepha okubaluleke kakhulu, umthelela wokugqoka kumathuluzi nokubumba.

Ikhwalithi yokulawula & Ukuhlola

Esikhathini esiyinkimbinkimbi sokwenza okunembile komjovo ukwenza isikhunta, kubalulekile ukuqinisekisa ukuthi isikhunta ngasinye sihlangabezana nokucaciswa okucacisiwe kanye namazinga athile.

Okubaluleke kakhulu kokunemba

- Ukubekezelelana microscopic: ukuqonda nokuphatha izinselelo zokugcina ukunemba ngokubekezelela okungakanani microscopic.

- Umthelela oqondile emikhiqizweni yokugcina: Ukubona ukuthi ukunemba kwezikhulwane kuhumushela kanjani ngqo kwikhwalithi nokusebenza kwezinto ezenziwe.

Imigomo yokulawula yekhwalithi

- Ukuqinisekiswa Kwemiklamo: Ukuqinisekisa ukuklama okubumba kunamandla futhi kunamathela kuzo zombili izinsiza zethiyori nakusebenzayo.

- Ukuqinisekiswa Kwezinto Ezibonakalayo: Ukuqinisekisa ukuthi izinto zokwakha ezisetshenziswe ekubumbeni isikhunta zihambisana namazinga asetshenzisiwe futhi alungele izinhlelo ezihlosiwe.

- Ukuqinisekiswa Kwezinqubo: Ukwengamela okuqhubekayo kwenqubo yokwenza isikhunta ukuze kuqinisekiswe ukubambelela ezinhlakeni ezinqunyelwe kusengaphambili amaphrothokholi namabhentshi.

Amasu wokuhlola nobuchwepheshe

- Ukuhlolwa okubukwayo: Ukuthumela ochwepheshe abanamakhono ukwenza ukuhlola okubukwayo okunemininingwane ngezigaba ezahlukahlukene zenqubo yokwenza isikhunta.

- Ingculazi yezobuchwepheshe: Ukuqalisa ubuchwepheshe njengokuhlola okuyisisekelo se-computer (cai) nokuxhumanisa imishini yokulinganisa (CMM) ukuthuthukisa ukunemba kokuhlola.

- Ukuhlolwa okungelonakalisayo (i-NDT): Ukusebenzisa amasu anjengokuhlolwa kwe-ultrasonic kanye nokuhlolwa kwe-x-ray ukuhlola isikhunta ngaphandle kokulimaza noma yimuphi umonakalo noma ukuguqulwa.

Ukulungisa nokulungisa ukushiyeka

- Amaphrothokholi wokulungisa: Ukusebenzisa izinqubo ezijwayelekile zokubhekana nokulungisa ukushiyeka okukhonjwe ngesikhathi sokuhlola.

- Ukuhlaziywa kwezimpande ze-Root: Ukuhambisa izindlela ukukhomba nokubhekana nezimbangela zezinkinga, kuvimbela ukuphindeka kwazo.

- Ukuthuthuka okuqhubekayo: Ukuzibandakanya kwinqubo eqhubekayo yempendulo, ukulungiswa, kanye nokwenza ngcono ukuthuthukisa ikhwalithi ephelele kanye nokusebenza kahle.

Imibhalo nokuhambisana

- Imibhalo yekhwalithi: Ukubhala ngokucophelela ukulawulwa kwekhwalithi nezinqubo zokuhlola, okutholakele kanye nezenzo zokulungisa.

- Ukuqinisekiswa kokuhambisana nakho: Ukuqinisekisa ukuthi zonke izinqubo zokulawula ezisezingeni eliphezulu nezinqubo zokuhlola zihambisana namazinga afanele endawo, kazwelonke, kanye namazwe aphesheya.

- Ukulungiswa kwamabhuku: ukulugcina ukulungela ukuhlolwa kwangaphakathi nangaphandle ukuze kuqinisekiswe ukusebenza nokuhambisana nezinqubo zokulawula ezisezingeni.

Ukuhlaziya Ukugeleza Kwesikhunta & Ukudiliza kahle

Ukuhlola izici zobuchwepheshe zendalo yokubumba, ukuhlaziya kokugeleza kokubumba, kanye nokwenza kahle ukwakhiwa kwamandla njengezigaba ezibucayi. Kubalulekile ukuqinisekisa ukuthi izinto ezibunjiweyo zigeleza kahle ngokusebenzisa isikhunta nokuthi ukwakheka kuhlanjululwa ukusebenza kahle kanye nekhwalithi.

Okuyisisekelo kokuhlaziywa kokugeleza kokubumba

- Injongo nokubaluleka: Ukuvusa ukuthi kungani ukuhlaziya ukugeleza kokuqina kokugeleza kubalulekile ekulindeleni izinselelo ezingaba khona.

- Ubuchwepheshe be-Simulation: Ukusebenzisa amathuluzi okulingisa athuthukile ukubona ngeso lengqondo ukuhamba kwezinto, ukukhomba izingqinamba ezingaba khona, nokwenza izixazululo.

- Ukuhlaziywa kwedatha: Ukuhlaziya idatha kusuka ekulinganiseni ukuqonda amandla ahlukahlukene wokugeleza okubonakalayo ngaphakathi kwesikhunta.

Ukuhlonza Izinselelo Ezihlobene Ukugeleza

- Imigqa yeWeld nezicupho zomoya: Ukuthola izindawo ezithambekele ekwakheni imigqa ye-weld kanye nezicupho zomoya ezingabeka engcupheni umkhiqizo.

- Ukuxineka kwe-Shear: Ukuhlaziya izifunda zengcindezi ephezulu ye-shear ethinta izakhiwo ezibonakalayo nekhwalithi yomkhiqizo.

- Ukupholisa ukungahambisani: Ukuhlonza ukungahambisani okungaba khona ekupholiseni okuholela ekulimaleni nasezindabeni zekhwalithi.

Design Optimization Strategielization

- Idizayini ye-Iterative: Ikwamukela indlela yokusebenzisa, njalo ekuthuthukiseni ukwakheka kwesikhunta kususelwa ekuhlaziyweni kokuhlaziywa kwe-Flow.

- Ukulinganisa ama-aesthetics nokusebenza: ukushaya ibhalansi entekenteke phakathi kokugcina isikhalazo sobuhle nokuqinisekisa ukuthembeka okusebenzayo komkhiqizo wokugcina.

- Ukusebenza kahle Kwezinto Ezibonakalayo: Ukulungiselela ukwakhiwa ukuze kuqinisekiswe ukusetshenziswa okuncane kwezinto ezibonakalayo ngenkathi ugcina ikhwalithi yomkhiqizo nokusebenza.

Ukukhetha okubonakalayo kanye nomthelela wawo ekuhambeni

- Izici ezibonakalayo: Ukuqonda ukuthi zihluke kangakanani izinto ezibonakalayo (njengokuvunywa, ukuvumelanisa, njll.) Ukuthonya ukugeleza ngaphakathi kwesikhunta.

- Ukuvumelanisa okubonakalayo: Ukuqinisekisa ukwakheka kwesikhunta kusetshenziselwa ukwamukela futhi kwandise izici ezikhethiwe.

Ukuhlanganisa impendulo ngokuthuthuka okuqhubekayo

- Isebenzisa idatha ye-Real-World: Ukufaka imininingwane kanye nemininingwane ethathwe ekukhiqizweni kwangempela kugijimisa ukuqhubeka nokuhlaziya okubumba.

- Amamodeli wokuqamba ama-Adaptive: Ukusebenzisa amamodeli avumelanayo angaguqulwa futhi alungiswe ngokwezidingo zokuvela kanye nentuthuko yezobuchwepheshe.

- Izifundo ze-Cross-Project: Ukusebenzisa izifundo nokuqonda kusuka kuphrojekthi eyodwa ukuze ulindele futhi kuzulazule izinselelo ngokuzayo.

Ubuchwepheshe obuthuthukisiwe kanye nemibono yesikhathi esizayo

Uhambo lokunemba lokubumbana luvela luvela njalo, lubunjwe yigagasi eliqhubekayo lentuthuko yezobuchwepheshe nemibono emisha ebeka ikusasa lokukhiqiza.

Kufaka ubuhlakani bokufakelwa (AI)

I-Artificial Intelligence ingena ngokuqinile izindawo zokwenza isikhunta ngu:

- Ukulondolozwa Kokubikezela: Ukusebenzisa i-AI ukuze ulindele futhi ulindele umshini wamakheli wokuqamba kanye nezidingo zokulungisa, ukunciphisa izikhathi ezingahlelwanga futhi uqinisekise ukunemba okuqhubekayo.

- Ukuqinisekiswa kwekhwalithi: Ukusebenzisa ama-algorithms ahlakaniphile ukubheka futhi aqinisekise ukubambelela kwekhwalithi kuyo yonke inqubo yokwenza isikhunta.

- Ukulungiswa kwenqubo: Ukuhlaziya idatha yesikhathi sangempela ukuze kuthuthukiswe ngamandla inqubo yokukhiqiza, ukuthuthukisa ukusebenza kahle kanye nekhwalithi yokuphuma.

Ukukhiqiza okungeziwe (ukuphrinta kwe-3D)

Ukukhiqiza okungeziwe, noma ukuphrinta kwe-3D, amaphayona amasha aphezulu ngo:

- I-PrototyPhing esheshayo: Ukusheshisa ukwakheka kwesikhunta kanye nezigaba zokuhlola ngendalo esheshayo, esebenza ngempumelelo ye-prototype.

- Ukwenza ngokwezifiso: Abakhiqizi abanika amandla ukuze bakhiqize ngempumelelo isikhunta esenziwe ngokwezifiso zemikhiqizo efushane noma izicelo ze-bespoke.

- Ukukhiqizwa kwe-geometry okuyinkimbinkimbi

Kufaka i-inthanethi yezinto (iot)

I-Intanethi Yezinto (IOT) iphakathi kwama-Realms ngokomzimba nakwedijithali, kwethulwa:

- Ukuqapha okude

- Izinqumo eziqhutshwa idatha: Ukuhlanganisa amandla emininingwane exhumekile ukwenza izinqumo ezinolwazi ezithuthukisa ukusebenza kahle

, ikhwalithi, nokusimama.

- Ukuhlaziya okubikezelwayo: Idatha ye-IOT yokufaka phansi ukubikezela nokuvimbela izingqinamba ezingaba khona, ukukhuthaza indlela esebenzayo yokuthola isikhunta.

Imikhuba eluhlaza futhi eqhubekayo

Ukugxila okwandayo kokusimama kwemvelo kwizenzo ezibandakanya:

- Izinto zokwenziwa ezinobungane

- Ukusebenza kahle kwamandla: Ukusebenzisa izinqubo zokukhiqiza ezisebenza kahle kanye nemishini.

- Ukuncishiswa kwemfucuza: ukunciphisa imfucumfucu yokungcola ngesikhathi sokwenza isikhunta nokuphela kokuvuselelwa kabusha kwezikhunta.

Isiphetho

Ukwenza kahle ukujova kokujoyina inclusion kungukuhlanganiswa kwengqondo kwemininingwane ebonakalayo nokunemba kwesayensi, ukushayela okusha kuyo yonke imboni efana nezimboni ezinjengokunakekelwa kwempilo, i-aerospe, elektroniki kanye nezimoto. Isebenza ngemuva kwezigcawu, yakha izimpilo zethu zansuku zonke. Uma ubheka phambili, kuzovela okunye, kuhlanganisa i-AI, ukuphrinta kwe-3D, i-IOT, kanye nokusimama kokuthola kabusha amathuba. Ukunemba akusona nje kuyindinganiso, kungubha okhuphukayo, futhi ikhwalithi ayinqunyelwe. Ukuchazwa ngokunemba kokuhlolisisa ukwenza ubuhlakani bomuntu, ukuma kude ezweni lapho nemininingwane emincane kakhulu inemininingwane emincane kakhulu ibamba amandla obukhulu.