Kuyini ukubumba komjovo wepulasitiki?

Ukubumba umjovo wepulasitiki kufana neqhinga lomlingo lokwenza zonke izinhlobo zezinto zepulasitiki. Isebenza ngokuncibilikisa ipulasitiki, iyifaka esikhunjeni, bese iyayipholisa ukwenza yonke into kusukela kumathoyizi kuya ezingxenyeni zomshini.

Yiziphi ezinye zezinkinga ezijwayelekile zokubumba umjovo wepulasitiki?

Ukubumba komjovo wepulasitiki kungahlangabezana nezinkinga ezahlukahlukene ezithinta ikhwalithi yomkhiqizo, ubuhle, nokusebenza kahle. Lezi zinkinga zisuka kokonakala okungaphezulu okufana nezimpawu zokusha nemigqa kuya ezindabeni zesakhiwo njenge-warpage kanye nokuqina.

Kungani kubalulekile ukugwema izinkinga zokubumba umjovo wepulasitiki?

Ngezinye izikhathi, umlingo awusebenzi kahle. Ipulasitiki ingaphuma ingalungile, ibangele izinkinga. Lezi zinkinga zingenza izinto zibukeke zimbi, zisebenze kabi, futhi kubize ngisho nangaphezulu ukuzilungisa. Kungakho kubalulekile ukwazi ukuthi ungazinqanda kanjani lezi zinkinga.

Ukuphatha Izinto kanye Nokungcola

Cabanga ngokwenza izinto zepulasitiki njengokubhaka ikhekhe. Uma usebenzisa amaqanda amabi noma ufulawa, ikhekhe ngeke linambithe kahle. Ekubumbeni ipulasitiki, izinto esiqala ngazo kufanele zihlanzeke futhi ziphelele. Uma kungenjalo, sithola izingxenye ezimbi zepulasitiki.

Inhlanzeko Yempahla

Ukuqinisekisa ukuhlanzeka kwe-resin yepulasitiki kubaluleke kakhulu. Ngisho nemithanjana emincane yezinto zangaphandle, njengothuli, umswakama, noma ukungcola, kungaholela ekulimaleni okufana nama-voids, streaks, noma ngisho nobuthakathaka besakhiwo kumkhiqizo oqediwe.

Imikhuba Engcono Kakhulu Yokuphatha Izinto

Ukuphatha impahla efanele kuyisisekelo sokuvimbela amaphutha. Abakhiqizi kufanele basungule futhi bahambisane nezinqubo eziqinile zokugcina impahla, ukuthutha, nokulayisha. Nazi ezinye izinqubo ezihamba phambili ezibalulekile:

- Izimo Zokugcina: Impahla yepulasitiki eluhlaza kufanele igcinwe endaweni elawulwayo enezimo zezinga lokushisa kanye nomswakamo ezihambisana nokucaciswa kwezinto. Lokhu kuvimbela ukumuncwa komswakama kanye nokuwohloka kwezinto.

- Ukuhlola Izinto: Njalo hlola ukuthunyelwa kwezinto ezingenayo ukuze uthole izimpawu zomonakalo noma ukungcola. Yenqaba noma yikuphi okubalulekile okungahlangabezani nezindinganiso zekhwalithi.

- Ukomisa kanye Nemibandela Yangaphambili: Ama-resin amaningi epulasitiki ane-hygroscopic, okusho ukuthi amunca umswakama emoyeni. Ukomisa kanye nokubeka i-preconditioning yizinyathelo ezibalulekile ngaphambi kokucutshungulwa ukuze kukhishwe noma imuphi umswakama omuncwe.

- Ukuphatha Okuhlanzekile: Abasebenzisi kufanele bagqoke amagilavu futhi basebenzise amathuluzi ahlanzekile lapho bephatha impahla. Ukugwema ukuthintana nezandla ezingenalutho kusiza ekuvimbeleni ukutheleleka.

- Izinto Ezihlanzekile: Qinisekisa ukuthi zonke izinto zokusebenza, okuhlanganisa ama-hopper nama-conveyor, zihlanzekile futhi azinayo imfucumfucu ngaphambi kokwethula okubalulekile.

- Ukulawula Uthuli: Sebenzisa izindlela zokulawula uthuli endaweni yokukhiqiza ukuze unciphise ubungozi bokungcola okuphuma emoyeni okuhlala kumpahla.

Ukuvimbela Nokutholwa

Ukuthola ukungcoliswa kwempahla ngaphambi kokuthi kungene emshinini wokubumba umjovo kubalulekile. Ubuchwepheshe besimanje, njengamasistimu okuhlola angaphakathi komugqa nezinzwa ezithuthukisiwe, bungasiza ekuboneni ukungqubuzana kwekhwalithi yezinto ezibonakalayo ngesikhathi sangempela, okuvumela isenzo sokulungisa esisheshayo. Chofoza ukuze ufunde ukuthi ungakhetha kanjani impahla yepulasitiki.

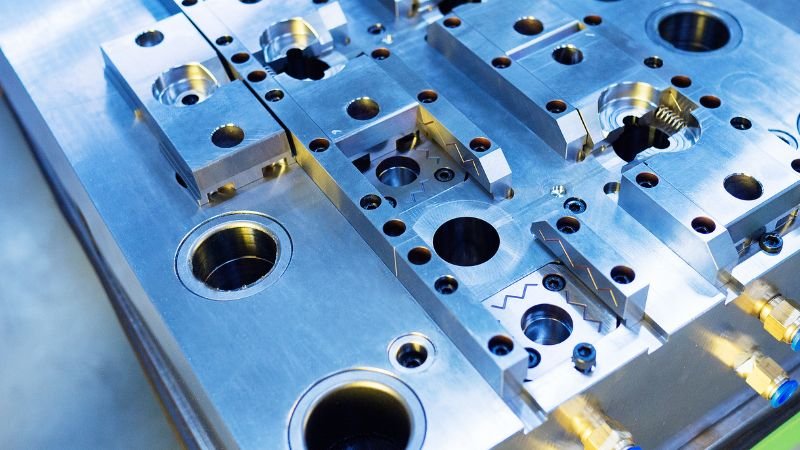

I-Mold Design kanye nokukhipha umoya

Inhliziyo yanoma iyiphi inqubo ephumelelayo yokubumba umjovo wepulasitiki ilele esikhunjeni ngokwaso. Isikhunta esiklanywe kahle asigcini nje ngokusho uhlobo lomkhiqizo wokugcina kodwa futhi sidlala indima ebalulekile ekuvimbeleni amaphutha. Idizayini yesikhunta ihlanganisa izakhi ezihlukahlukene, kusukela ekwakhiweni komgodi kanye nokubekwa kwesango kuya ezixazululweni zokungenisa umoya, konke okuthinta ngokuqondile ikhwalithi yezingxenye eziqediwe.

Air Traps

Izicupho zomoya, noma amaphakethe omoya avaleleke ngaphakathi kwesikhunta, yinkinga evamile engabangela ukulimala okungathandeki njengama-voids, ukusha, nokuqedwa kahle kwendawo. Lezi zingibe zomoya ezicasulayo zenzeka lapho umoya uvaleleka ngesikhathi somjovo, uvimbela ipulasitiki encibilikisiwe ukuthi ingagcwali imbobo ngokuphelele.

Iqhaza Lokukhipha Isikhunta

Ukukhipha isikhunta okusebenzayo kuyisihluthulelo sokuvimbela izingibe zomoya. Ukukhipha umoya kuhilela ukuhlinzeka ngemigudu ukuze umoya ovaleleke uphume emgodini wesikhunta njengoba ipulasitiki encibilikisiwe ijovwa. Ukukhipha umoya ngendlela efanele kuvumela ukugcwaliswa okufanayo kwesikhunta futhi kuqinisekisa ukuthi umoya awubambeki, okuholela ekulimaleni.

- I-Vent Design: Onjiniyela baklama ngokucophelela izimbobo zokuvula isikhunta ukuze kube lula ukukhululwa komoya ngaphandle kokuphazamisa ubuqotho bomkhiqizo wokugcina. Lezi zintuba ngokuvamile ziba mincane futhi zibekwe ngendlela efanele ezindaweni lapho umoya okungenzeka uvaleleke khona.

- I-Venting Material: Impahla yokukhipha umoya kufanele ikhethwe ngokucophelela ukuze imelane nokugwazwa kwenhlaka yepulasitiki futhi imelane nokuguga nokudabuka ngokuhamba kwesikhathi.

- Isondlo: Ukugcinwa kwesikhunta njalo kubalulekile ukugcina izintuba zihlanzekile futhi zingenazihibe. Ngokuhamba kwesikhathi, ukungcola noma izinsalela zepulasitiki zinganqwabelana ezintubeni, zivimbele ukusebenza kwazo.

Ukugqwala Kwesikhunta

Ukubola kwesikhunta kungenye inselele engathinta ikhwalithi yemikhiqizo ebunjwe ngomjovo. Ukugqwala kwenzeka lapho isikhunta siwohloka ngenxa yezici ezihlukahlukene, okuhlanganisa imvelo enolaka yamanye ama-resin epulasitiki, umswakama, nokushintshashintsha kwezinga lokushisa.

Amasu Okuvimbela Ukugqwala Kwesikhunta

Ukuvimbela ukubola kwesikhunta kudinga indlela esebenzayo:

- Ukukhethwa Kwezinto Zokubumba: Khetha izinto zokubumba ezimelana nokugqwala futhi ezifanele inhlaka yepulasitiki ethile ecutshungulwayo. Insimbi engagqwali kanye nezimbotshana ezimelana nokugqwala yizinketho ezisebenzayo.

- Ukugcinwa kwe-Vent: Njalo uhlole futhi unakekele izintuba ukuze uvimbele ukugqwala. Ukuhlanza nokusebenzisa izinto ezivikelayo kungandisa impilo yezikhala.

- Ukulawulwa Kwemvelo: Gcina imvelo yokukhiqiza ngaphakathi kwebanga lokushisa elicacisiwe kanye nomswakama ukuze unciphise amathuba okugqwala kwesikhunta. Kubalulekile kukho kokubili ukuphila isikhathi eside kwesikhunta kanye nekhwalithi yomkhiqizo wokugcina.

- Ukwelapha Okungaphezulu: Ukusebenzisa okokunamathela okukhethekile noma ukwelapha okungaphezulu kungasiza ukuvikela isikhunta ekugqwaleni.

- Ukunakekela Okusebenzayo: Sebenzisa uhlelo olusebenzayo lokulungisa isikhunta oluhlanganisa ukuhlanzwa okujwayelekile kanye nokuhlolwa ukuze kutholwe futhi kulungiswe izinkinga zokubola ngaphambi kokuba zande.

Ukubekwa Kwesango Lesikhunta

Ukubekwa kwesango kungesinye isici esibalulekile sokwakheka kwesikhunta esingaba nomthelela omkhulu kwikhwalithi yezingxenye ezibunjwe ngomjovo. Isango liyindawo yokungena lapho ipulasitiki encibilikisiwe ingena khona emgodini wesikhunta. Ukubekwa kwesango ngendlela efanele kubalulekile ukuze kuqinisekiswe ukugcwaliswa okufanayo, ukunciphisa amaphutha, kanye nokufeza izakhiwo zengxenye oyifunayo.

Izinhlobo Zesango Nokukhethwa

Izinhlobo ezahlukene zamasango ziyatholakala, ngalinye linezinzuzo zalo kanye nokulinganiselwa kwalo. Ukukhethwa kohlobo lwesango kuncike ezicini ezihlukahlukene, kuhlanganise nomklamo wengxenye, impahla, kanye nevolumu yokukhiqiza. Izinhlobo zamasango ezivamile zihlanganisa:

- Isango eliqondile le-Sprue: Kutholakala ngqo ku-sprue, lolu hlobo lwesango lunikeza indlela eqondile yokugeleza kwezinto ezibonakalayo. Ngokuvamile isetshenziselwa izingxenye ezinkulu.

- Isango Lomkhumbi Wamanzi: Lolu hlobo lwesango lutholakala ngaphansi kwendawo, okwenza lungabonakali emkhiqizweni oqediwe.

- Isango Lomphetho: Ibekwe emaphethelweni engxenye, lolu hlobo lwesango lufanele izingxenye ezinejometri eyinkimbinkimbi.

- Hot Runner System: Kuhlelo lomgijimi oshisayo, ipulasitiki encibilikisiwe igcinwa ekushiseni okuphakeme, okuvumela amasango amaningi ngaphandle kwesidingo sabagijimi. Lokhu kunciphisa udoti wezinto ezibonakalayo futhi kuvame ukusetshenziswa ekukhiqizeni umthamo omkhulu.

Usayizi Wesango kanye neJiyomethri

Ubukhulu kanye nejometri yesango nakho kudlala indima ebalulekile enqubweni yokubumba umjovo. Isango elincane kakhulu lingakhawulela ukugeleza kwempahla futhi liholele ezinkingeni zokugcwalisa, kuyilapho isango elikhulu lingase libangele ukusetshenziswa okweqile kwempahla kanye nokukhubazeka kwezimonyo.

- Ukuthuthukisa Usayizi Wesango: Onjiniyela babala ngokucophelela futhi bakhulise usayizi wesango ngokusekelwe kuzinto ezifana nezakhiwo ezibonakalayo, ukwakheka kwengxenye, nezimfuneko zokukhiqiza.

- Isango Jiyomethri: Ukuma kwesango kuthinta ukugeleza kwezinto ezibonakalayo nokucindezeleka kwe-shear. Amasango ayindilinga noma ane-tapered ngokuvamile akhethwa ukunciphisa ukugxila kwengcindezi kanye nokukhubazeka kwezimonyo.

I-Art of Multiple Gates

Kwezinye izimo, ukusebenzisa amasango amaningi kungathuthukisa inqubo yokubumba umjovo. Amasango amaningi abekwe ngendlela ehlelekile ukuze kuzuzwe ngisho nokusatshalaliswa kwezinto ezibonakalayo, ukunciphisa ubungozi bemigqa yokugeleza noma imigqa yokushisela, nokuqinisekisa ukupakishwa okufanayo kwesigxobo sesikhunta.

- Ukugeleza Okulinganiselayo: Amasango amaningi avumela ukugeleza kwezinto ezilinganiselayo ekubunjweni, ukunciphisa ingozi yokugcwalisa okungalingani kanye nokukhubazeka.

- Ukubukeka Kwezimonyo Okuthuthukisiwe: Amasango amaningi anganciphisa ukubukeka kwezimpawu zesango kumkhiqizo oqediwe, athuthukise ukukhanga kwawo kwezimonyo.

- Ubuqotho Besakhiwo Esithuthukisiwe: Ukugcwalisa nokupakisha okufanayo, okwenziwa amasango amaningi, kufaka isandla ekuthuthukisweni kwamandla engxenye nobuqotho besakhiwo.

Ukulawula Ukushisa Kwesikhunta

Ukulawulwa kwezinga lokushisa kwesikhunta kuyisici esibalulekile ekubunjweni komjovo wepulasitiki okungaba nomthelela omkhulu kwikhwalithi yengxenye, ubuhle, nokusebenza. Ukugcina izinga lokushisa lesikhunta elingaguquki nelifanayo kuyo yonke inqubo yokukhiqiza kubalulekile ukuze kuvinjelwe amaphutha afana ne-warpage, izimpawu zokucwila, nokungalungi kobukhulu.

Ukubaluleka Kwezinga Lokushisa Kwesikhunta

Izinga lokushisa lesikhunta lithinta izici ezahlukahlukene zenqubo yokubumba umjovo:

- Ukugeleza Kwempahla: Izinga lokushisa elifanele lesikhunta liqinisekisa ukuthi ipulasitiki encibilikisiwe igeleza kahle emgodini wesikhunta, inciphisa amaphutha.

- Ukupholisa: Izinga lokushisa lesikhunta elilinganayo libalulekile ekupholiseni okulinganayo nangempumelelo kwengxenye, ukuvimbela i-warpage nezinye izinkinga.

- Isikhathi Somjikelezo: Ukuthuthukisa izinga lokushisa kwesikhunta kungaholela ezikhathini ezincishisiwe zomjikelezo, ukwandisa ukusebenza kahle kokukhiqiza.

Ukufinyelela Izinga Lokushisa Lesikhunta Esifanayo

Ukugcina izinga lokushisa lesikhunta elingaguquki kudinga ukulawula nokuqapha ngokucophelela. Nawa amanye amasu okuthola izinga lokushisa elifanayo lesikhunta:

- Iziteshi zokupholisa: Iziteshi zokupholisa eziklanywe kahle esikhunjeni zisiza ukusabalalisa okupholisayo ngokulinganayo, ukuvimbela izindawo ezishisayo noma izindawo ezibandayo.

- Uhlobo Lokupholisa kanye Nezinga Lokugeleza: Ukukhetha into epholile kanye nezinga lokugeleza kwayo yizici ezibalulekile. Amapholisa anezinto ezinhle kakhulu zokudlulisa ukushisa namaphethini okugeleza athuthukisiwe ayakhethwa.

- Amasistimu okulawula izinga lokushisa: Ukusebenzisa izinhlelo ezithuthukisiwe zokulawula izinga lokushisa kuvumela ukulawulwa okunembile kwamazinga okushisa esikhunta. Lokhu kuqinisekisa ukuthi isikhunta sihlala ngaphakathi kwebanga lokushisa elincane ngesikhathi sokukhiqiza.

- Ukubhekana Nokwehluka Kwezinga Lokushisa Kwesikhunta: Ukushintshashintsha kwezinga lokushisa ngaphakathi kwesikhunta kungaholela ekupholiseni okungalingani futhi, ngenxa yalokho, amaphutha. Ukugcinwa kwesikhunta njalo nokulungiswa kubalulekile ukuze kuncishiswe izinga lokushisa.

Hlola Isevisi ye-PMS Mold Tooling

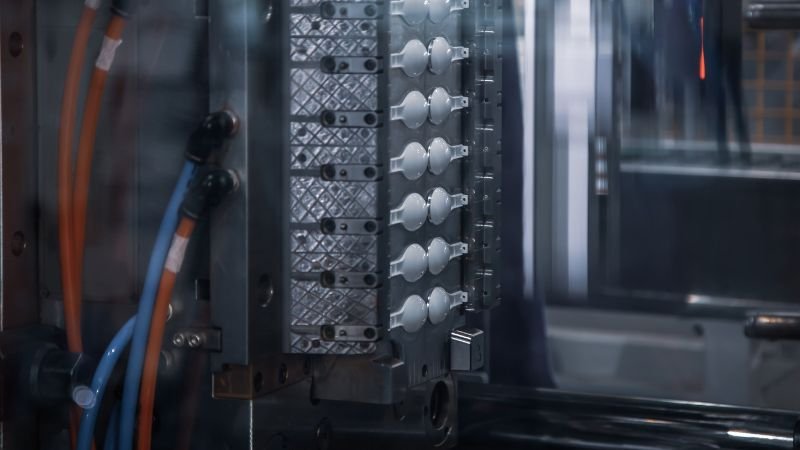

Njengoba siqhubekela phambili nenqubo yokubumba umjovo wepulasitiki, sifika esigabeni somjovo, okuyindawo lapho impahla yepulasitiki encibilikisiwe ifakwa emgodini wokukhunta.

Amashothi Amafushane: Lapho Ukugcwaliswa Kwehla Kafushane

Ukudubula okufushane kwenzeka lapho isikhunta singagcwaliswanga ngokuphelele ngesikhathi sokujova. Lokhu kuholela ezingxenyeni ezingaphelele noma ezincane, okungaba yinkinga ebalulekile, ikakhulukazi uma ukunemba nokuvumelana kubaluleke kakhulu.

Izimbangela Zokudubula Okufushane

Ukudubula okufushane kungabangelwa izici ezihlukahlukene, ezihlanganisa:

- Impahla enganele: Umthamo wezinto ezibonakalayo onganele ungabangela ukushutha okufushane. Lokhu kungase kwenzeke ngenxa yamaphutha ekubalweni kwezinto ezibonakalayo noma ukungasebenzi kahle kweyunithi yomjovo.

- Isikhunta Design: Ukuklama okungalungile kwesikhunta, kufaka phakathi usayizi wesango nendawo, kungakhawulela ukuhamba kwepulasitiki futhi kuholele ekugcwaliseni okungaphelele.

- Izinga Lokushisa Nengcindezi: Izinga lokushisa elingalungile noma izilungiselelo zokucindezela zingavimbela ikhono lempahla lokugeleza kuzo zonke izindawo zesikhunta.

Amakhambi Okudubula Okufushane

Ukubhekana nesibhamu esifushane kudinga ukucatshangelwa ngokucophelela kwezici ezimbalwa:

- Ukulungiswa Kwevolumu Yezinto: Qinisekisa ukuthi inani elilungile lempahla lijovwa esibunjeni ngokulinganisa nokuqinisekisa izilungiselelo zeyunithi yomjovo.

- Ukubuyekezwa Kwedizayini Yesikhunta: Buyekeza njalo futhi uthuthukise imiklamo yesikhunta ukuze uqinisekise ukuthi usayizi wesango nendawo kusiza ukugcwaliswa komgodi ophelele.

- Ukulawula izinga lokushisa nokucindezela: Lawula ngokunembile izilungiselelo zokushisa nengcindezi ukuze ukhuthaze ukugeleza kwezinto ezibonakalayo kuzo zonke izingxenye zesikhunta.

Ukupakisha ngokweqile: Ingozi Yokweqisa

Ngenkathi amashothi amafushane eshiya izingxenye zingagcwali kakhulu, ukupakisha ngokweqile kubandakanya ukujova inani eliningi lezinto ezibonakalayo esibunjeni. Lokhu kungaholela ekulimaleni okufana ne-warpage, i-flash, noma ngisho nokulimala kwesikhunta ngokwaso.

Izimbangela Zokupakisha Okungaphezulu

Ukupakisha ngokweqile kungenzeka ngenxa yalokhu:

- Isivinini Sokujova Ngokweqile: Ukujova izinto ngokushesha kakhulu kungaholela ekupakishweni ngokweqile njengoba ipulasitiki encibilikisiwe ihlangabezana nokumelana nesikhunta.

- Ukucindezela Okuphezulu: Ingcindezi yomjovo ephakeme ingabangela ukuthi impahla ipakishwe iqine kakhulu ngaphakathi kwesikhunta, okuholela ekupakishweni ngokweqile.

Ukuzuza Ukunemba Komjovo

Ukulinganisa isidingo sokugcwaliswa kwe-cavity ephelele nokugwema ukupakisha kudinga ukulawula okunembile nokuqapha. Abakhiqizi kumele bagxile kulokhu:

- Isivinini sokujova: Lungisa ijubane lomjovo ukuze uqinisekise ukuthi isikhunta sigcwaliswa ngokwanele ngaphandle kwengozi yokupakisha ngokweqile.

- Ukulawula Ingcindezi: Sebenzisa amasistimu okulawula ingcindezi agcina amazinga okucindezela alungile kuyo yonke inqubo yomjovo.

- Ukuhlaziywa Kokugeleza Okubalulekile: Sebenzisa isofthiwe namathuluzi okuhlaziya ukuze ulingise ukuhamba kwezinto ngaphakathi kwesikhunta, uhlonze izinkinga ezingaba khona ngaphambi kokukhiqiza.

- Ukubuyekezwa Kwedizayini Yesikhunta: Buyekeza njalo imiklamo yesikhunta ukuze uqinisekise ukuthi ubukhulu besango nendawo kusiza ukugcwaliswa okuphelele ngaphandle kokupakisha ngokweqile.

Funda Inqubo yokubumba umjovo we-PMS

Njengoba sithuthukela ezigabeni zokubumba umjovo wepulasitiki, sifinyelela esigabeni sokukhipha, lapho umkhiqizo wokugcina ukhishwa esikhunjeni. Lesi sinyathelo esibonakala siqondile sibonisa izinselele zaso eziyingqayizivele ezingathinta ikhwalithi nokubukeka kwengxenye eqediwe.

I-Ejector Pin Marks

Omaki bephini lokukhipa ukungapheleli okuvamile okungangonakalisa ubuso bomkhiqizo ongenasici. Lezi zimpawu zenzeka lapho izikhonkwane ze-ejector, ezisetshenziselwa ukusunduza umkhiqizo ngaphandle kwesikhunta, zishiya ngemuva ama-indents amancane noma amabala.

Izimbangela ze-Ejector Pin Marks

Iphinikhodi ye-ejector ingabangelwa izici ezihlukahlukene, okuhlanganisa:

- I-Ejector Pin Design: Idizayini enganele, njengokusetshenziswa kwezikhonkwane ezinkulu kakhulu noma ezincane, kungabangela amamaki aqaphelekayo endaweni yomkhiqizo.

- I-Ejector Pin Positioning: Izikhonkwane ze-ejector ezimiswe kabi zingabangela amamaki ezindaweni ezisobala, kuthinte ubuhle bomkhiqizo.

- Isivinini sokujova: Isivinini somjovo esiphezulu singandisa amandla lapho izikhonkwane ze-ejector ziphusha izingxenye ngaphandle kwesikhunta, okuholela kumamaki.

Ukungalingani Kokugcwalisa Isikhunta

Ukungalingani kokugcwalisa isikhunta kwenzeka lapho izinto zepulasitiki ezincibilikisiwe zingagelezi ngokulinganayo kulo lonke isikhunta, okuholela ezingxenyeni ezingahambisani nobukhulu nezakhiwo.

Izimbangela Zokungalingani Kokugcwalisa Isikhunta

Kunezici ezimbalwa ezingaba nomthelela ekungalinganini kokugcwalisa isikhunta, okuhlanganisa:

- Umklamo Wesango Ongenele: Amasango amancane kakhulu noma abekwe ngendlela engafanele angaphazamisa ukugeleza okulinganayo kwempahla yepulasitiki.

- Ukwehluka kwezinga lokushisa: Amazinga okushisa esikhunta angalingani angathinta ukugeleza kwezinto ezibonakalayo, okuholela ekugcwaliseni ukungalingani.

- I-Viscosity yezinto ezibonakalayo: Ukwehluka kwe-viscosity yezinto kungabangela ukugcwaliswa okungalingani.

Amakhambi Ezimpawu Zephinikhodi Ye-Ejector kanye Nokungalingani Kokugcwalisa

Ukubhekana nalezi zinkinga kudinga inhlanganisela yokuklama ngokucophelela, ukulawula okunembayo, nezinqubo zokunakekela:

- Ukubuyekezwa Kwedizayini Ye-Ejector Pin: Buyekeza njalo umklamo wephinikhodi ye-ejector ukuze uqinisekise usayizi ofanele kanye nokuma. Cabangela ukusetshenziswa kwezikhonkwane eziningi ukusabalalisa amandla ngokulinganayo.

- Ukuthuthukisa Isango: Lungiselela umklamo wesango ukuze uthole ngisho nokugeleza kwezinto ezibonakalayo. Indawo efanele yesango nosayizi kunganciphisa kakhulu ukungalingani kokugcwalisa.

- Ukulawula izinga lokushisa: Gcina izinga lokushisa elifanayo lesikhunta ukuze uqinisekise ukugeleza kwezinto ezingaguquki.

- Ukukhetha Okubalulekile: Khetha izinto ezinezici ze-viscosity ezingaguquki ukuze unciphise ingozi yokugcwalisa ukungalingani.

Isikhathi Somjikelezo

Ukulungiselela isikhathi somjikelezo kuyisici esibalulekile sokucatshangelwa kwangemva komjovo. Isho umzamo wokunciphisa isikhathi esithathayo ukuqedela umjikelezo ngamunye wenqubo yokubumba umjovo, ukusuka kumjovo wezinto ezibonakalayo kuye ekukhishweni kwengxenye.

Izinto Ezithinta Isikhathi Somjikelezo

Kunezici ezimbalwa ezithonya isikhathi somjikelezo, okuhlanganisa:

- Isivinini sokujova: Ukulungisa isivinini somjovo kungathinta isikhathi somjikelezo. Isivinini sokujova esisheshayo singanciphisa isikhathi esidingekayo sokugcwalisa isikhunta kodwa singathula ezinye izinkinga.

- Isikhathi Sokupholisa: Isikhathi sokupholisa sinegalelo elibalulekile esikhathini somjikelezo. Ukuthuthukisa amasu okupholisa kungasiza ukunciphisa izikhathi zomjikelezo.

- Inqubo Yokukhipha: Izindlela zokukhipha ezisebenzayo zingasiza ukunciphisa isikhathi esichithwe kususwa izingxenye esikhunjeni.

I-Warpage

I-Warpage iyinselele eqhubekayo ekubunjweni komjovo wepulasitiki, futhi kungenzeka ezigabeni ezahlukahlukene zenqubo. I-Warpage ibandakanya ukuwohloka noma ukuhlanekezela kwengxenye ebunjiwe, okuholela ekuchezukeni kumumo noma ubukhulu obuhlosiwe.

Izimbangela ze-Warpage

I-Warpage ingabangelwa izici eziningana:

- Ukupholisa Okungalingani: Ukwehluka kwamazinga okupholisa kungaholela ekuncipheni okuhlukile kanye ne-warpage.

- Ukukhetha Okubalulekile: Ukukhethwa kwezinto kudlala indima ebalulekile ku-warpage. Ezinye izinto ezisetshenziswayo zithambekele ekubeni ne-warpage kunezinye.

- Ingxenye Design: Idizayini yengxenye engalungile, okuhlanganisa ukuhlukahluka kokuqina kodonga okudlulele, kungandisa ingozi ye-warpage.

Amasu Okuvimbela kanye Nokunciphisa Amakhasi e-Warpage

Ukubhekana ne-warpage kudinga indlela enezici eziningi:

- Ukupholisa Isu: Lungiselela amasu okupholisa ukuze unciphise ukupholisa okuhlukile futhi unciphise ubungozi be-warpage.

- Ukukhetha Okubalulekile: Khetha ngokucophelela izinto ezisetshenziswayo ezingathambekele kangako ku-warpage yezinhlelo zokusebenza ezithile.

- Ingxenye Design Review: Qhubeka ubuyekeze izingxenye zemiklamo ukuze uhlonze imithombo engaba khona ye-warpage futhi usebenzise ukuthuthukiswa kwedizayini.

Sihlangabezana nesethi entsha yezinkinga ezidinga ukuthi sizinake. Lezi zinkinga zihlanganisa inkungu, ama-sink marks, imigqa yokushisela, kanye nenkinga enzima yama-streaks.

Burn Marks: Izibazi Zokushisisa

Burn marks, owaziwa nangokuthi “izimpawu zofakazi” noma “amabhamuza,” yizindawo ezinemibala engathandeki ebusweni bezingxenye ezibunjiwe. Zivame ukuvela eduze kwesango noma ezingxenyeni eziminyene zengxenye futhi ziwumphumela wokushisa okweqile kwasendaweni ngesikhathi sokujova.

Izimbangela Zokushiswa Kwezimpawu

Izimpawu zokushiswa zingabangelwa izici eziningana:

- Isivinini Sokujova Ngokweqile: Umjovo osheshayo wepulasitiki encibilikisiwe ungadala ukushisa okudlulele, okuholela ezimpawu zokusha.

- Ukupholisa Okungenele: Ukupholisa okunganele kungavumela ukushisa ukuthi kunqwabelane ezindaweni zendawo, kubangele izimpawu zokusha.

- Ukuwohloka kwe-Resin Material: Amanye ama-resin epulasitiki athambekele kakhulu ekuwohlokeni kokushisa, okuholela ezimpawu zokusha.

I-Delamination: I-Layered Dilemma

I-Delamination isho ukuhlukaniswa kwezingqimba ngaphakathi kwengxenye ebunjiwe. Ngokuvamile kubonakala njengemigqa ebonakalayo noma ukuhlukaniswa, okuphazamisa kokubili ubuqotho besakhiwo kanye nobuhle.

Izinkinga zeDelamination

I-Delamination ingenzeka ngenxa yalokhu:

- Ukuxuba Izinto Ezingenele: Ukuxubana okungalungile kwezinto ngesikhathi sokubumba kungaholela ku-delamination.

- Ukungcola Okubalulekile: Ukungcola okwethulwa ngesikhathi sokuphatha noma ukucubungula kungabangela izendlalelo ukuthi zihlukane.

- I-Melt Temperature enganele: Izilungiselelo ezingalungile zezinga lokushisa lokuncibilika zingaba nomthelela ekuncipheni.

I-Jetting: I-Speed Dilemma

I-Jetting isenzakalo lapho umfudlana wesivinini esikhulu wezinto zepulasitiki ezincibilikisiwe zithinta indawo yesikhunta, zidale ama-streaks abonakalayo noma imigqa engxenyeni eqediwe. Ngokuvamile kuhlotshaniswa nokusetshenziswa kwezinto eziphezulu ze-viscosity.

Izinkinga Jetting

I-Jetting ingadalwa yilokhu:

- Isivinini Sokujova Esiphezulu: Isivinini somjovo esidlulele singaholela ekujikeni, njengoba okokusebenza kuthinta indawo yesikhunta kunokugeleza ngokushelela emigodini.

- ISango Design: Ukuklama kwesango okungalungile kungandisa izinkinga ze-jetting.

Imigqa Egelezayo: Indlela Yokumelana Kancane

Imigqa egelezayo, eyaziwa nangokuthi “imigqa yokushisela” noma “imigqa elukiwe,” zivame ukubonakala njengemigqa efiphele noma amagquma ebusweni bengxenye. Zenzeka lapho ukugeleza kwezinto zepulasitiki ezincibilikisiwe kuhlangabezana nokuphikiswa futhi kuhlangana kabusha, kushiye umthungo obonakalayo.

Izimbangela Zemigqa Egelezayo

Imigqa egelezayo ingabangelwa:

- Ukupholisa Okubalulekile: Ukwehluka kwamazinga okupholisa kungabangela impahla ukuthi iqine ngezikhathi ezihlukene, okuholela emigqeni yokugeleza.

- Ingxenye Yejiyomethri Eyinkimbinkimbi: Izingxenye ezinamajiyometri ayinkimbinkimbi noma amagatsha amaningi asengozini yokugeleza imigqa.

Amasu Okunciphisa Isici

Ukunciphisa lezi zinkinga kudinga inhlanganisela yedizayini, ukuthuthukiswa kwenqubo, nokukhetha okubalulekile:

- Isango Ukuklama Kabusha: Ukuklanywa kwesango ngendlela efanele kanye nokubekwa kunganciphisa ingcuphe yezimpawu zokusha, i-delamination, kanye ne-jetting.

- Isivinini Somjovo Esilungiselelwe: Lawula isivinini somjovo ukuze uvimbele ukushisa ngokweqile nokujetha ngenkathi uqinisekisa ukugeleza kwezinto ezifanele.

- Ukukhetha Okubalulekile: Khetha izinto ezingajwayele ukushiswa amamaki kanye ne-delamination.

- I-Tooling kanye ne-Mold Design: Sebenzisa izinguquko zamathuluzi kanye nokuthuthukiswa kwesakhiwo sesikhunta ukuze unciphise amathuba okugeleza kwemigqa.

Inkungu: Inkungu Yokungapheleli

Inkungu, evame ukubizwa ngokuthi “ukucwenga” noma “ukuqunjelwa,” ibonakala njengendawo eguqubele noma enolufifi engxenyeni ebunjiwe. Lesi sici singathinta kakhulu ubuhle nokucaca komkhiqizo.

Izimbangela Zenkungu

Inkungu ingenzeka ngenxa yalokhu:

- Ukungcola Okubalulekile: Ukungcola okwethulwa ngesikhathi sokuphatha noma ukucutshungulwa kungaholela enkungu.

- Ukushisa ngokweqile: Amazinga okushisa adlulele phakathi nenqubo yokubumba angabangela ukuba impahla yonakale, kubangele inkungu.

Sink Marks: Inselele Yokungeniswa

Amamaki osinki amadengezi noma ama-indentation ebusweni bengxenye ebunjiwe. Zenzeka lapho ingaphezulu lengxenye ejiyile yengxenye liphola futhi liqina kancane kunezindawo zangaphakathi.

Izimbangela Zezimpawu Zokucwila

Izimpawu zokucwila zingabangelwa:

- Ukupholisa Okungenele: Ukupholisa okungalingani, ikakhulukazi ezingxenyeni ezijiyile zengxenye, kungaholela emamaki osinki.

- Ukuncipha Kwempahla: Amazinga okuncipha ahlukile ngaphakathi kwengxenye angabangela amamaki osinki.

Imigqa Ye-Weld: Lapho Izinto Ezisetshenziswayo Zihlangana Khona

Imigqa yokushisela, eyaziwa nangokuthi “imigqa elukiwe,” kwenzeka lapho izingxenye ezimbili noma ngaphezulu zepulasitiki ezincibilikisiwe zihlangana futhi zihlangana kabusha phakathi nenqubo yomjovo. Le migqa ivame ukubonakala ebusweni bengxenye eqediwe futhi ingathinta ubuqotho bayo besakhiwo.

Izimbangela ze-Weld Lines

Imigqa yokushisela ingakheka ngenxa yokuthi:

- Imikhawulo yokugeleza kwezinto: Izithiyo noma i-geometry ngaphakathi kwesikhunta kungabangela ukugeleza kwezinto ezibonakalayo kuhlukane futhi kujoyine kabusha.

- Ukupholisa Okubalulekile: Ukwehluka kwamazinga okupholisa kungaholela ekwakhekeni kwemigqa yokushisela.

Imivimbo: Amamaki Angabukeki

Imigqa, njengoba igama layo liphakamisa, imigqa ebonakalayo noma imigqa ebusweni bengxenye ebunjiwe. Zingabangelwa izici ezihlukahlukene futhi ngokuvamile ziyinselele ukuxilonga nokuxazulula.

Izimbangela Zemivimbo

Ukulandelana kungabangelwa:

- Ukungcola Okubalulekile: Ukungcola noma ukungcola kokubalulekile kungabangela imivimbo.

- Ukuxuba Okungenele: Ukuxuba okungalungile kwezinto kungaholela ekwakhekeni kwe-streak.

Amasu okuxazulula iphutha

Ukuxazulula lezi zinselele kudinga inhlanganisela yedizayini, ukuthuthukiswa kwenqubo, nokuphathwa kwezinto ezibonakalayo:

- Ubumsulwa Bezinto ezibonakalayo: Qinisekisa ukuthi impahla esetshenzisiwe ayinakho ukungcola nokungcola.

- Ukuthuthukisa Ukupholisa: Lungiselela amasu okupholisa ukuze unciphise ubungozi bezimpawu zokucwila kanye nenkungu.

- Ukubuyekezwa Kwedizayini Yesikhunta: Qhubeka ubuyekeze imiklamo yesikhunta ukuze uhlonze imithombo engaba khona yemigqa ye-weld ne-streaks.

- Ukukhetha Okubalulekile: Khetha ngokucophelela izinto zokwakha ezingajwayele ukwakheka kwe-streak nokunye ukukhubazeka.