Isixazululo sokubumba umjovo wePlastiki

Umhlahlandlela ophelele wesinyathelo ngesinyathelo

Ukubumba komjovo wepulasitiki kuyinqubo yokukhiqiza eyinkimbinkimbi nenembayo eguqula izinto zepulasitiki ezingavuthiwe zibe yizinhlobonhlobo zemikhiqizo enobumo obuyinkimbinkimbi nobukhulu obunembayo.

Isinyathelo 1

Ukulungiselela Ukuklama kanye Nesikhunta

- Idizayini yomkhiqizo: Inqubo iqala ngomklamo womkhiqizo onemininingwane noma umqondo. Ukucatshangelwa kwedizayini kufaka phakathi ukusebenza, ubuhle, ukukhethwa kwezinto ezibonakalayo, nokwenza.

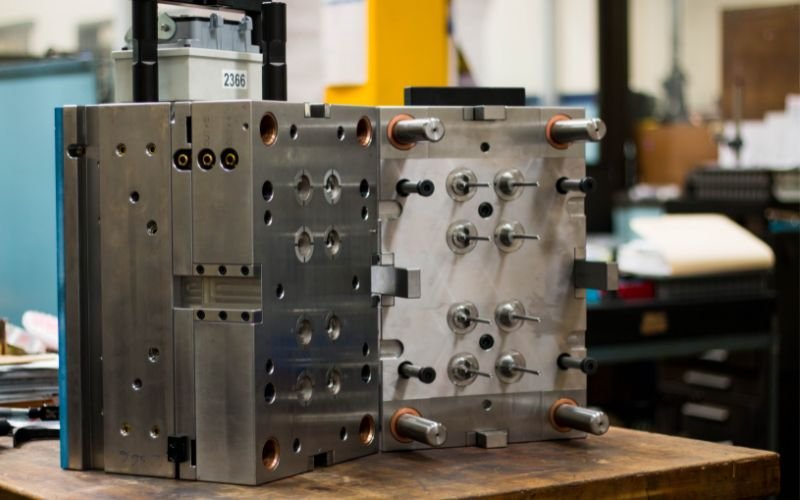

- I-Mold Design: Isikhunta, esaziwa nangokuthi ithuluzi noma siyafa, sidalwa ngokusekelwe ekwakhiweni komkhiqizo. Isikhunta siqukethe ama-halves amabili - umgodi kanye nomgogodla - okwenza isimo somkhiqizo wokugcina.

- Ukukhetha Okubalulekile: Khetha izinto ezifanele zepulasitiki ngokusekelwe ezidingweni zomkhiqizo, ucabangela izici ezifana nezakhiwo zemishini, ukumelana namakhemikhali, nokuzinza kwezinga lokushisa.

- Ukwenziwa Kwesikhunta: Abenzi bamathuluzi abanekhono benza isikhunta besebenzisa amasu omshini onembile. Ubunkimbinkimbi besikhunta nobukhulu buthonya isikhathi nezindleko zokwenziwa.

Isinyathelo sesi-2

Inqubo yokubumba umjovo

- Ukugoqa: Isikhunta sifakwa emshinini wokubumba umjovo. Ama-halves amabili avaliwe ngokuvikelekile kusetshenziswa amandla asebenza ngogesi noma asebenza ngomshini ukuze kuqinisekiswe ukuqondana okufanele.

- Umjovo: Amapulangwe epulasitiki, aziwa ngokuthi yi-resin, afakwa emshinini wokubumba umjovo. Ama-pellets ayashiswa futhi ancibilike ngaphakathi komgqomo ukuze abe nesimo esincibilikisiwe esingaguquki.

- Ingcindezi yomjovo kanye nesivinini: Ipulasitiki encibilikisiwe ifakwa emgodini wesikhunta ngaphansi kwengcindezi ephezulu. Isivinini somjovo nokucindezela kulawulwa ukuze kugcwaliswe isikhunta futhi kuvinjwe amaphutha njengama-voids noma ama-sink marks.

- Ukupholisa: Ngemva kokuba isikhunta sigcwalisiwe, ipulasitiki ngaphakathi iqala ukupholisa futhi iqine. Isikhathi sokupholisa silawulwa ngokucophelela ukuze kuzuzwe ingxenye yekhwalithi oyifunayo.

- Ukubamba Ingcindezi: Ezinye isikhunta zihlanganisa ingcindezi yokubamba ukunxephezela ukuncipha kwezinto ngesikhathi sokupholisa. Lokhu kuqinisekisa ukuthi ingxenye igcina umumo nobukhulu bayo.

Isinyathelo sesi-3

Ukuvuleka Nokukhishwa Kwesikhunta

- Ukupholisa Ukuqedwa: Lapho ipulasitiki isipholile ngokwanele futhi yaqina, isikhunta siyavuleka, siveze ingxenye eqinile ngaphakathi.

- Ukukhipha: Izikhonkwane ze-mold ejector ziphusha ingxenye iphume emgodini wesikhunta. Ukukhipha kufanele kube mnene ukugwema ukulimaza ingxenye yengxenye.

Isinyathelo sesi-4

Ngemuva kokucubungula

- Ukunciphisa nokunciphisa: Impahla eyeqile, ebizwa ngokuthi i-flash, iyasuswa engxenyeni. Ukunquma kungase kuhlanganise izinqubo ezenziwa ngesandla noma ezizenzakalelayo ukuze kuzuzwe umumo wokugcina.

- Imisebenzi yesibili: Ngokuya ngezidingo zomkhiqizo, izinqubo ezengeziwe ezifana nokubhola, ukukhanda imishini, noma ukuhlanganisa zingenziwa.

Isinyathelo sesi-5

Ukulawula Ikhwalithi Nokuhlola

- Ukuhlola Okubonakalayo: Ingxenye ngayinye ihlolelwa ukukhubazeka, njengokungapheleli kwendawo, ukungahambisani kwemibala, noma ukuhlanekezela.

- Ukuhlolwa kobukhulu: Izingxenye ziyalinganiswa futhi ziqhathaniswe nezicaciso ezivezwe ekwakhiweni. Imishini yokulinganisa ethuthukisiwe iqinisekisa ukunemba.

Isinyathelo sesi-6

Ukupakisha kanye Nokuthumela

- Ukupakishwa: Izingxenye eziqediwe zipakishwa ngokucophelela ukuvimbela ukulimala ngesikhathi sokuthutha.

- Ukuthumela: Izingxenye zithunyelwa ekhasimendeni noma endaweni yokuhlanganisa ukuze zihlanganiswe nemikhiqizo emikhulu noma zisakazwe kubasebenzisi bokugcina.