Yintoni ukubumba inaliti yeplastiki?

Ukubumba inaliti yeplastiki kufana neqhinga lomlingo lokwenza zonke iintlobo zezinto zeplastiki. Isebenza ngokunyibilikisa iplastiki, ifakwe kwisingundo, kwaye emva koko ipholise ukwenza yonke into ukusuka kwizinto zokudlala ukuya kwiindawo zoomatshini.

Zeziphi ezinye iingxaki eziqhelekileyo zokubumba inaliti yeplastiki?

Ukubumba inaliti yeplastiki kunokuhlangabezana nemiba eyahlukeneyo echaphazela umgangatho wemveliso, ubuhle kunye nokusebenza kakuhle. Ezi ngxaki zisuka kwiziphene zomphezulu ezifana namanqaku atshileyo kunye nemigca ukuya kwimiba yesakhiwo efana ne-warpage kunye nokuqina.

Kutheni kubalulekile ukuphepha iingxaki zokubumba inaliti yeplastiki?

Ngamanye amaxesha, umlingo awusebenzi ngokugqibeleleyo. Iplastiki inokuphuma ingalunganga, ibangele iingxaki. Ezi ngxaki zisenokwenza izinto zibonakale zimbi, zisebenze kakubi, kwaye zide zibe neendleko ezingaphezulu ukulungisa. Yiyo loo nto kubalulekile ukwazi indlela yokuthintela ezi ngxaki.

UkuPhathwa kweMathiriyeli kunye nokuNgcolisa

Cinga ngokwenza izinto zeplastiki njengokubhaka ikeyiki. Ukuba usebenzisa amaqanda amabi okanye umgubo, ikhekhe ayiyi kunambitha kakuhle. Ekubunjweni kweplastiki, izinto esiqala ngazo kufuneka zicoceke kwaye zigqibelele. Ukuba akunjalo, sifumana iindawo ezimbi zeplastiki.

Ukucoceka kwezinto eziphathekayo

Ukuqinisekisa ukucoceka kwe-resin yeplastiki kubaluleke kakhulu. Kwanemithanjana emincinane yezinto zasemzini, njengothuli, ukufuma, okanye izinto ezingcolisayo, zinokukhokelela kwiziphene ezinjengokungavakali, imitya, okanye kwanobuthathaka besakhiwo kwimveliso egqityiweyo.

UkuPhathwa kweMathiriyeli Ezona zenzo zilungileyo

Ukuphathwa kwezinto ezifanelekileyo kusisiseko sokuthintela isiphene. Abavelisi kufuneka baseke kwaye babambelele kwiinkqubo ezingqongqo zokugcina imathiriyeli, ukuthutha, kunye nokulayisha. Nazi ezinye iindlela eziphambili zokuziphatha:

- Iimeko zokuGcina: Izinto zeplastiki eluhlaza kufuneka zigcinwe kwindawo elawulwayo kunye neemeko zokushisa kunye nokufuma okuhambelana neenkcukacha zezinto. Oku kuthintela ukufunxwa kokufuma kunye nokuthotywa kwezinto.

- Ukuhlolwa kwezinto: Hlola rhoqo ukuthunyelwa kwezinto ezingenayo ukufumana iimpawu zomonakalo okanye ungcoliseko. Yala nayiphi na into engahambelani nemigangatho yomgangatho.

- Ukomisa kunye ne-Preconditioning: Iintlaka ezininzi zeplastiki zine-hygroscopic, oku kuthetha ukuba zifunxa ukufuma emoyeni. Ukomisa kunye ne-preconditioning ngamanyathelo ayimfuneko phambi kokuba kusetyenzwe ukususa nakuphi na ukufuma okufunthiweyo.

- Ukuphatha okucocekileyo: Abaqhubi kufuneka banxibe iiglavu kwaye basebenzise izixhobo ezicocekileyo xa bephethe imathiriyeli. Ukuphepha ukunxibelelana nezandla ezingenanto kunceda ukuthintela ukosuleleka.

- Izixhobo ezicocekileyo: Qinisekisa ukuba zonke izixhobo, kubandakanywa iihoppers kunye neconveyors, zicocekile kwaye azinankunkuma phambi kokwazisa imathiriyeli.

- Ukulawula Uthuli: Sebenzisa imilinganiselo yokulawula uthuli kwindawo yokuvelisa ukunciphisa umngcipheko wongcoliseko olusemoyeni oluhlala kwizinto eziphathekayo.

Uthintelo kunye nokuFumana

Ukufumanisa ukungcoliseka kwezinto phambi kokuba kungene umatshini wokubumba inaliti kubalulekile. Itekhnoloji yale mihla, enje ngeenkqubo zokuhlola ezingaphakathi kunye nezinzwa eziphambili, zinokunceda ekuchongeni ukungangqinelani kumgangatho wezinto eziphathekayo ngexesha lokwenyani, nto leyo evumela ukuba kuthathwe amanyathelo okulungisa ngokukhawuleza. Cofa ukuze ufunde indlela yokukhetha imathiriyeli yeplastiki.

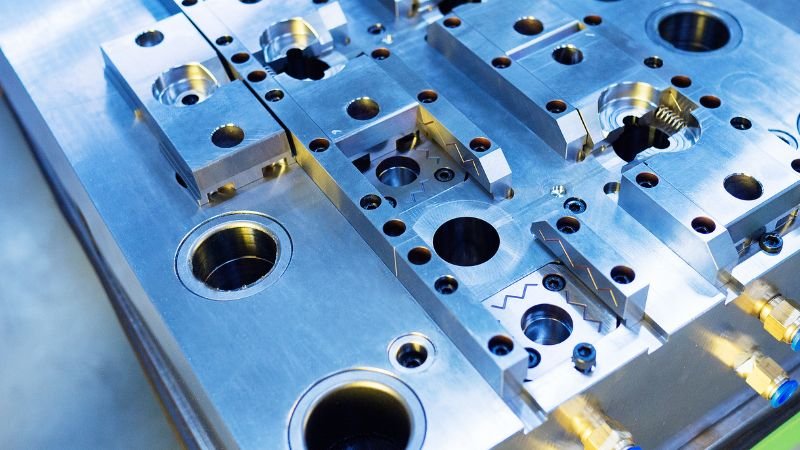

Uyilo lokungunda kunye nokuPhumelela

Intliziyo yayo nayiphi na inkqubo eyimpumelelo yokubumba inaliti yeplastiki ilele kumngundo ngokwawo. Umngundo owenziwe kakuhle awuthethi nje kuphela ifom yemveliso yokugqibela kodwa udlala indima ebalulekileyo ekuthinteleni iziphene. Uyilo lokungunda lubandakanya izinto ezahlukeneyo, ukusuka kwisakhiwo somgodi kunye nokubekwa kwesango ukuya kwizisombululo zokukhupha umoya, zonke ezichaphazela ngokuthe ngqo umgangatho wamacandelo agqityiweyo.

Imigibe yomoya

Imigibe yomoya, okanye iipokotho zomoya ezivaleleke ngaphakathi kumngundo, ngumba oqhelekileyo onokubangela iziphene ezingafunekiyo ezinje nge-voids, ukutsha, kunye nokungagqibeki komphezulu. Le migibe yomoya iyingozi yenzeka xa umoya uvaleleka ngexesha lenkqubo yokutofa, ukuthintela iplastiki etyhidiweyo ukuba igcwalise umngxuma ngokupheleleyo.

Indima yokuPhumeza uMngundo

Ukukhutshwa komngundo okusebenzayo ngundoqo wokuthintela imigibe yomoya. Ukungenisa umoya kubandakanya ukubonelela ngeendledlana zomoya ovalelekileyo ukuba uphume kumgodi wokungunda njengoko iplastiki enyibilikisiweyo itofwa. Ukukhupha umoya ngokufanelekileyo kuvumela ukuzaliswa okufanayo kwesikhunta kwaye kuqinisekise ukuba umoya awubanjwanga, okukhokelela kwiziphene.

- Uyilo lweVent: Iinjineli ziyila ngokucokisekileyo imingxuma ekubumbeni ukuze kube lula ukukhutshwa komoya ngaphandle kokubeka esichengeni isidima semveliso yokugqibela. Le mijelo ikholisa ukubamxinwa kwaye ibekwe ngobuchule kwiindawo apho umoya unokuvaleleka khona.

- Izinto zokukhupha umoya: Izinto zokungenisa umoya kufuneka zikhethwe ngononophelo ukumelana nendalo erhabaxa yentlaka yeplastiki kunye nokumelana nokuguga nokukrazuka kwexesha.

- Isondlo: Ukugcinwa rhoqo komngundo kubalulekile ukugcina iminyango icocekile kwaye ingenazithintelo. Ngokuhamba kwexesha, ungcoliseko okanye intsalela yeplastiki inokuqokelelana kwimingxuma, ithintele ukusebenza kwayo.

Ukonakala kokungunda

Ukubola komngundo ngomnye umngeni onokuchaphazela umgangatho weemveliso ezibunjwe ngenaliti. Ukonakala kwenzeka xa imathiriyeli yokungunda isiba mandundu ngenxa yezizathu ezahlukeneyo, kubandakanya ubundlongondlongo bezinye iintlaka zeplastiki, ukufuma, kunye nokuguquguquka kobushushu.

Ubuchule bokuThintelwa kokuMngunda

Ukuthintela ukubola kokungunda kufuna indlela esebenzayo:

- Ukukhethwa kwezinto zokungunda: Khetha imathiriyeli yokungunda ekwaziyo ukumelana nomhlwa kwaye ifanele i-resin yeplastiki ethile eyenziwayo. Insimbi engenasici kunye ne-corrosion-resistant-resistant coatings zikhetho ezinokubakho.

- Ukugcinwa kweVent: Hlola rhoqo kwaye ugcine iminyango ukuthintela umhlwa. Ukucoca kunye nokusebenzisa iingubo ezikhuselayo kunokwandisa ubomi bemizila.

- Ulawulo lokusingqongileyo: Gcina imo engqongileyo yokwenziwa komgangatho wobushushu obuchaziweyo kunye nokufuma ukuze kuncitshiswe ukubakho kokudleka kokungunda. Kubalulekile kubomi obude bokubumba kunye nomgangatho wemveliso yokugqibela.

- Unyango loMphezulu: Ukusebenzisa iingubo ezikhethekileyo okanye unyango olungaphezulu lunokunceda ukukhusela isikhunta kwi-corrosion.

- ULondolozo olusebenzayo: Qalisa inkqubo yogcino lokungunda olusebenzayo olubandakanya ukucocwa kwesiqhelo kunye nokuhlolwa ukuze kubonwe kwaye kulungiswe imiba yokukhula phambi kokuba inyuke.

Ukubekwa kweSango lokuMbumba

Ukubekwa kwesango ngomnye umba obalulekileyo woyilo lokungunda onokuchaphazela kakhulu umgangatho wamalungu abunjiweyo. Isango yindawo yokungena apho iplastiki etyhidiweyo ingena kumngxuma wokungunda. Ukubekwa kwesango ngokufanelekileyo kubalulekile ekuqinisekiseni ukuzaliswa okufanayo, ukunciphisa iziphene, kunye nokufezekisa iipropati ezifunwayo zenxalenye.

Iintlobo zeSango kunye noKhetho

Iindidi ezahlukeneyo zamasango ziyafumaneka, nganye ineengenelo zayo kunye nemida. Ukukhethwa kohlobo lwesango kuxhomekeke kwizinto ezahlukeneyo, kubandakanywa uyilo lwenxalenye, izinto eziphathekayo kunye nomthamo wemveliso. Iindidi zesango eziqhelekileyo ziquka:

- Isango elithe ngqo leSprue: Ifakwe ngokuthe ngqo kwi-sprue, olu hlobo lwesango lubonelela ngendlela echanekileyo yokuhamba kwezinto. Isetyenziswa rhoqo kwiindawo ezinkulu.

- Isango leNkwidi: Olu hlobo lwesango lubekwe ngaphantsi kwendawo, okwenza lungabonakali kwimveliso egqityiweyo.

- Isango loMda: Ibekwe kumda wecandelo, olu hlobo lwesango lufanelekile kwiindawo ezinejometri eziyinkimbinkimbi.

- Inkqubo yeMbaleki eshushu: Kwinkqubo yomgijimi oshushu, iplastiki etyhidiweyo igcinwa kwiqondo lokushisa eliphakamileyo, livumela amasango amaninzi ngaphandle kwesidingo sabagijimi. Oku kunciphisa inkunkuma yezinto kwaye ihlala isetyenziswa kwimveliso ephezulu.

Ubungakanani beSango kunye neJometri

Ubungakanani kunye nejometri yesango nayo idlala indima ebalulekileyo kwinkqubo yokubumba inaliti. Isango elincinane kakhulu linokuthintela ukuhamba kwezinto kwaye likhokelela kwimiba yokuzalisa, ngelixa isango elikhulu kakhulu linokubangela ukusetyenziswa okugqithisileyo kunye neziphene zokuthambisa.

- ULungiselelo lobungakanani beSango: Iinjineli zibala ngocoselelo kwaye zandise ubungakanani besango ngokusekwe kwizinto ezifana neempawu zezinto eziphathekayo, uyilo lwenxalenye, kunye neemfuno zemveliso.

- ISango leJiyometri: Ubume besango buchaphazela ukuhamba kwezinto kunye noxinzelelo lwe-chear. Amasango ajikelezileyo okanye anetapered ahlala ekhethwa ukunciphisa uxinzelelo kunye neziphene zokuthambisa.

UbuGcisa baMasango amaninzi

Kwezinye iimeko, ukusebenzisa amasango amaninzi kunokuphucula inkqubo yokubumba inaliti. Amasango amaninzi abekwe ngobuchule ukuphumeza ukuhanjiswa kwezinto, ukunciphisa umngcipheko wemigca yokuhamba okanye imigca ye-weld, kunye nokuqinisekisa ukupakishwa okufanayo kwendawo yokubumba.

- Ukuqukuqela okuLingeneyo: Amasango amaninzi avumela ukuhamba kwezinto ezinokulinganisela kwi-mold, ukunciphisa umngcipheko wokuzaliswa kokungalingani kunye neziphene.

- Imbonakalo yeCosmetic ephuculweyo: Amasango amaninzi anokunciphisa ukubonakala kwamanqaku esango kwimveliso egqityiweyo, ephucula isibheno sayo sokuthambisa.

- Ukwandiswa kweMfezeko yoLwakhiwo: Ukuzaliswa okufanayo kunye nokupakisha, okuququzelelwa ngamasango amaninzi, igalelo ekuphuculeni amandla enxalenye kunye nokuthembeka kwesakhiwo.

Ulawulo lobushushu boMngundo

Ulawulo lobushushu bomngundo yeyona nto ibalulekileyo ekubunjweni kwenaliti yeplastiki enokuthi ibe nefuthe elikhulu kwinxalenye yomgangatho, ubuhle, kunye nokusebenza. Ukugcina ubushushu bomngundo obungaguqukiyo kunye nobufanayo kuyo yonke inkqubo yemveliso kubalulekile ukuthintela iziphene ezifana ne-warpage, amanqaku e-sink, kunye nokungachaneki kobukhulu.

Ukubaluleka kobushushu boMngundo

Ubushushu bomngundo buchaphazela imiba eyahlukeneyo yenkqubo yokubumba inaliti:

- Ukuqukuqela kwezinto: Ubushushu obufanelekileyo bokubumba buqinisekisa ukuba iplastiki etyhidiweyo ihamba kakuhle kwi-mold cavity, ukunciphisa iziphene.

- Ukupholisa: Ubushushu obufanayo bokungunda buyimfuneko ekupholiseni ngokulinganayo nangokufanelekileyo kwenxalenye, ukuthintela i-warpage kunye neminye imiba.

- Ixesha lomjikelo: Ukuphucula ubushushu bokubumba kunokukhokelela ekunciphiseni amaxesha okujikeleza, ukwandisa ukusebenza kakuhle kwemveliso.

Ukufezekisa ubushushu obufanayo boMngundo

Ukugcina ubushushu obufanayo bokungunda kufuna ukulawulwa ngononophelo kunye nokubeka iliso. Nazi ezinye izicwangciso zokuphumeza ubushushu obufanayo bokungunda:

- Imijelo yokupholisa: Iitshaneli zokupholisa ezenziwe kakuhle kwi-mold zinceda ukusabalalisa ukupholisa ngokulinganayo, ukukhusela iindawo ezishushu okanye iindawo ezibandayo.

- Uhlobo lokupholisa kunye nenqanaba lokuHamba: Ukhetho lwesipholisi kunye nesantya sokuhamba kwayo yimiba ebalulekileyo. Izipholisi ezineempawu ezibalaseleyo zokudlulisa ubushushu kunye neepateni zokuqukuqela eziphuculweyo ziyakhethwa.

- Iinkqubo zokulawula ubushushu: Ukuphumeza iinkqubo zokulawula ubushushu obuphambili kuvumela ukulawulwa ngokuchanekileyo kobushushu bomngundo. Oku kuqinisekisa ukuba ukungunda kuhlala ngaphakathi kwinqanaba elimxinwa lobushushu ngexesha lemveliso.

- Ukujongana noMahluko woBubushushu boMngundo: Ukutshintsha kweqondo lokushisa ngaphakathi kwesikhunta kunokukhokelela ekupholiseni okungalinganiyo kwaye, ngenxa yoko, iziphene. Ukugcinwa rhoqo kunye nohlengahlengiso lokungunda kubalulekile ukulwa nokutshintsha kwamaqondo obushushu.

Jonga iNkonzo ye-PMS Mold Tooling

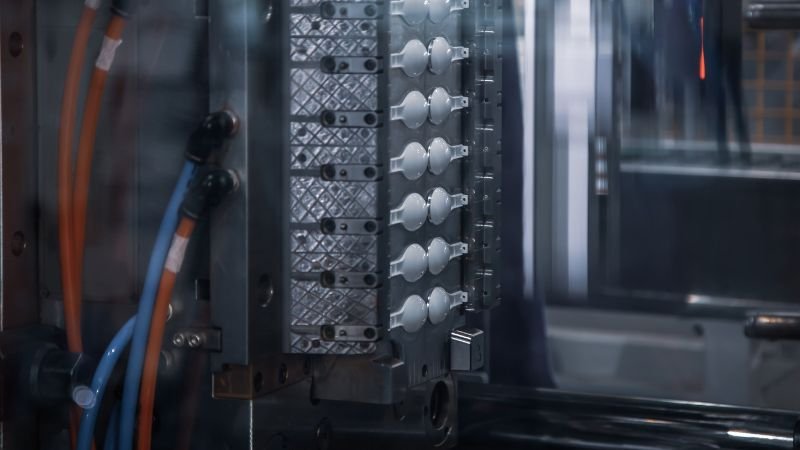

Njengoko siqhubela phambili nenkqubo yokubumba inaliti yeplastiki, sifika kwinqanaba lokutofa, eliyindawo apho imathiriyeli yeplastiki etyhidiweyo ingeniswa kumgodi wokungunda.

IiShots ezimfutshane: Xa ukuZaliswa kuwela kuMfutshane

Ukudubula okufutshane kwenzeka xa i-mold cavity ingagcwaliswanga ngokupheleleyo ngexesha lesigaba sokutofa. Oku kukhokelela kumalungu angaphelelanga okanye abe ngaphantsi, nto leyo enokuba ngumba obalulekileyo, ngakumbi xa ukuchaneka kunye nokungaguquguquki kubaluleke kakhulu.

Iimbangela zeShots ezimfutshane

Ukudubula okufutshane kunokubangelwa zizinto ezahlukeneyo, eziquka:

- Izinto ezingonelanga: Umthamo wezinto eziphathekayo onganelanga unokubangela ukudubula okufutshane. Oku kunokwenzeka ngenxa yeempazamo kubalo lwemathiriyeli okanye ukungasebenzi kakuhle kweyunithi yokutofa.

- Uyilo lokungunda: Uyilo olungafanelekanga lokubumba, kubandakanywa ubungakanani besango kunye nendawo, lunokuthintela ukuhamba kweplastiki kwaye lukhokelela ekuzalisweni okungaphelelanga.

- Ubushushu kunye noxinzelelo: Ukushisa okungachanekanga okanye izicwangciso zoxinzelelo kunokuthintela ukukwazi kwezinto eziphathekayo ukuhamba kuzo zonke iindawo zokubumba.

Izisombululo zeeShots ezimfutshane

Ukujongana neeshoti ezimfutshane kufuna uqwalaselo ngononophelo lwemiba emininzi:

- Ukulungelelaniswa Komthamo Wezinto eziphathekayo: Qinisekisa ukuba ubungakanani obuchanekileyo bezinto eziphathekayo bufakwe kwi-mold ngokulinganisa kunye nokuqinisekisa izicwangciso zeyunithi yenaliti.

- Uphononongo loYilo lokungunda: Uphononongo rhoqo kwaye ulungiselele uyilo lokungunda ukuqinisekisa ukuba ubungakanani besango kunye nendawo iququzelela ukuzaliswa komngxuma opheleleyo.

- Ubushushu kunye noLawulo loxinzelelo: Lawula ngokuchanekileyo ubushushu kunye noxinzelelo lwezicwangciso zokukhuthaza ukuhamba kwezinto kuzo zonke iindawo zokubumba.

Ukupakisha ngokugqithisileyo: Umgibe wokuBanxwa

Ngelixa izithonga ezimfutshane zishiya iindawo zingazaliswanga ngokwaneleyo, ukupakisha ngokugqithisileyo kubandakanya ukutofa isixa esigqithisileyo semathiriyeli kumngundo. Oku kunokukhokelela kwiziphene ezifana nephepha lemfazwe, ifleshi, okanye umonakalo kumngundo ngokwawo.

Iimbangela zokupakishwa ngokugqithisileyo

Ukupakisha ngaphezulu kungenzeka ngenxa:

- Isantya sokutofa ngokugqithisileyo: Ukutofa imathiriyeli ngokukhawuleza kunokukhokelela ekupakishweni ngokugqithisileyo njengoko iplastiki etyhidiweyo idibana nokuchasana nokungunda.

- Uxinzelelo oluphezulu: Uxinzelelo olunyusiweyo lwenaliti lunokubangela ukuba izinto zipakishwe ngokuqinileyo ngaphakathi kwesikhunta, okukhokelela ekugqithiseni.

Ukufezekisa ukuchaneka kwesitofu

Ukulinganisa imfuno yokuzaliswa kwecavity epheleleyo kunye nokuphepha ukugqithisa kufuna ukulawulwa okuchanekileyo kunye nokubeka iliso. Abavelisi kufuneka bagxile koku:

- Isantya sokutofa: Lungisa isantya senaliti ukuze uqinisekise ukuba i-mold cavity izaliswe ngokwaneleyo ngaphandle komngcipheko wokugqithisa.

- Ulawulo loxinzelelo: Ukusebenzisa iinkqubo zokulawula uxinzelelo ezigcina amanqanaba aphezulu oxinzelelo kuyo yonke inkqubo yokutofa.

- Uhlalutyo Lokuqukuqela kwezinto: Sebenzisa isoftware kunye nezixhobo zokuhlalutya ukulinganisa ukuhamba kwezinto ngaphakathi kwesikhunta, ukuchonga imiba enokubakho ngaphambi kokuveliswa.

- Uphononongo loYilo lokungunda: Uphonononge rhoqo uyilo lokubumba ukuze uqinisekise ukuba ubungakanani besango kunye nendawo iququzelela ukuzaliswa okupheleleyo ngaphandle kokupakisha.

Funda Inkqubo yokubumba i-PMS ye-Injection

Njengoko siqhubela phambili kwizigaba zokubumba inaliti yeplastiki, sifikelela kwisigaba se-ejection, apho imveliso yokugqibela ikhutshwa kwi-mold. Eli nyathelo elibonakala lithe ngqo libonisa imingeni yalo ekhethekileyo enokuchaphazela umgangatho kunye nokubonakala kwenxalenye egqityiweyo.

Amanqaku e-Ejector Pin

Iimpawu ze-Ejector pin ziziphene eziqhelekileyo ezinokonakalisa umphezulu wemveliso ngenye indlela engenasiphako. Ezi mpawu zenzeka xa izikhonkwane ze-ejector, ezisetyenziselwa ukutyhala imveliso ngaphandle kwesikhunta, zishiya ngasemva ama-idents amancinci okanye amabala.

Iimbangela ze-Ejector Pin Marks

Amanqaku e-Ejector pin angabalelwa kwizinto ezahlukeneyo, kuquka:

- I-Ejector Pin Design: Uyilo olungonelanga, olufana nokusetyenziswa kwezikhonkwane ezinkulu okanye ezincinci, kunokubangela amanqaku abonakalayo kumphezulu wemveliso.

- I-Ejector Pin Positioning: Izikhonkwane ze-ejector ezibekwe kakuhle zingabangela amanqaku kwiindawo ezibonakalayo, ezichaphazela i-aesthetics yemveliso.

- Isantya sokutofa: Isantya esiphezulu sokutofa sinokunyusa amandla apho izikhonkwane ze-ejector zityhala iindawo eziphuma kwi-mold, ezikhokelela kumanqaku.

Ukungalingani kokuzalisa umngundo

Ukungalingani kokuzaliswa kwesikhunta kwenzeka xa izinto zeplastiki ezityhidiweyo zingaqhubeki ngokulinganayo kulo lonke i-mold cavity, okubangela ukuba iindawo ezingahambelani nobukhulu kunye neepropati.

Iimbangela zokuzaliswa kokungalingani koMngundo

Izinto ezininzi zinokufaka isandla kukungalingani kokuzaliswa komngundo, kubandakanya:

- Uyilo lweSango olunganelanga: Amasango amancinci kakhulu okanye abekwe ngendlela engafanelekanga anokuthintela ukuhamba okulinganayo kwezinto zeplastiki.

- Ukwahluka kobushushu: Ubushushu obungalinganiyo bokubumba bunokuchaphazela ukuhamba kwezinto, okukhokelela ekuzaliseni ukungalingani.

- Viscosity yezinto eziphathekayo: Iinguqu kwi-viscosity yezinto eziphathekayo zingabangela ukuzaliswa kokungalingani.

Izisombululo zamanqaku e-Ejector Pin kunye nokuFikisha ukungalingani

Ukujongana nale miba kufuna indibaniselwano yoyilo olunenkathalo, ulawulo oluchanekileyo, kunye nezenzo zokulondoloza:

- Uphononongo loYilo lwe-Ejector Pin: Uphononongo rhoqo uyilo lwe-ejector pin ukuqinisekisa ubungakanani obufanelekileyo kunye nokuma. Cinga ngokusetyenziswa kwezikhonkwane ezininzi ukusabalalisa amandla ngokulinganayo.

- UPhuculo lweSango: Lungiselela uyilo lwesango lokuhamba kwezinto. Indawo efanelekileyo yesango kunye nobukhulu kunokunciphisa kakhulu ukungalingani kokuzalisa.

- Ulawulo lobushushu: Gcina ubushushu obufanayo bokungunda ukuqinisekisa ukuhamba kwezinto eziphathekayo.

- Ukukhethwa kwezinto: Khetha izinto eziphathekayo ezineempawu ze-viscosity ezihambelanayo ukunciphisa umngcipheko wokuzalisa ukungalingani.

Ixesha lomjikelo

Ukulungiswa kwexesha lomjikelo yinkalo ebalulekileyo yokuqwalaselwa emva kokutofa. Ibhekisa kumzamo wokunciphisa ixesha elithathayo ukugqiba umjikelo ngamnye wenkqubo yokubumba inaliti, ukusuka kwinaliti yezinto eziphathekayo ukuya kwi-ejection inxalenye.

Imiba echaphazela ixesha lomjikelo

Izinto ezininzi zinefuthe kwixesha lomjikelo, kuquka:

- Isantya sokutofa: Ukulungelelanisa isantya sokutofa kunokuchaphazela ixesha lomjikelo. Izantya zokutofa ezikhawulezayo zinokucutha ixesha elifunekayo lokugcwalisa ukungunda kodwa kunokwazisa eminye imiba.

- Ixesha lokupholisa: Ixesha lokupholisa ligalelo elibalulekileyo kwixesha lokujikeleza. Ukuphucula izicwangciso zokupholisa kunokuncedisa ukunciphisa amaxesha omjikelezo jikelele.

- Inkqubo yokukhupha: Iindlela zokukhupha ezisebenzayo zinokunceda ukunciphisa ixesha elichithwe ekususeni iinxalenye kwi-mold.

Warpage

I-Warpage ngumceli mngeni oqhubekayo wokubumba inaliti yeplastiki, kwaye ingenzeka kumanqanaba ahlukeneyo enkqubo. I-Warpage ibandakanya ukuguqulwa okanye ukugqwesa inxalenye ebunjiweyo, ekhokelela ekuphambukeni kwimilo ejoliswe kuyo okanye imilinganiselo.

Iimbangela zeWarpage

I-Warpage inokubangelwa zizinto ezininzi:

- Ukupholisa okungalinganiyo: Ukwahluka kwimilinganiselo yokupholisa kunokukhokelela ekunciphiseni okwahlukileyo kunye ne-warpage.

- Ukukhethwa kwezinto: Ukukhethwa kwezinto eziphathekayo kudlala indima ebalulekileyo kwi-warpage. Ezinye iimathiriyeli zithandwa kakhulu kwi-warpage kunezinye.

- Uyilo lwecandelo: Uyilo olubi lwenxalenye, kubandakanywa ukuguquguquka okukhulu kweendonga, kunokunyusa umngcipheko we-warpage.

Izicwangciso-qhinga zoThintelo lweWarpage kunye nokuNcitshiswa

Ukujongana nephepha lemfazwe kufuna indlela eneenkalo ezininzi:

- Isicwangciso sokupholisa: Ukwandisa izicwangciso zokupholisa ukunciphisa ukupholisa okwahlukileyo kunye nokunciphisa umngcipheko we-warpage.

- Ukukhethwa kwezinto: Khetha ngononophelo imathiriyeli ethandabuzeka kancinci kwi-warpage yezicelo ezithile.

- Uphononongo loYilo lweCandelo: Ngokuqhubekayo uphonononga uyilo lwenxalenye ukuchonga imithombo enokubakho ye-warpage kunye nokuphumeza ukuphuculwa koyilo.

Sidibana neqela elitsha lemiba efuna ingqalelo yethu. Le miba ibandakanya inkungu, amanqaku e-sink, imigca ye-weld, kunye nengxaki enqabileyo ye-streaks.

Amanqaku atshisiweyo: Izibonda zokutshisa ngokugqithisileyo

Amanqaku okutshisa, okwakwaziwa njenge “amanqaku amangqina” okanye “amadyunguza,” ziindawo ezingabukekiyo ezinombala omdaka kumphezulu weendawo ezibunjiweyo. Zihlala zivela kufuphi nesango okanye kumacandelo atyebileyo enxalenye kwaye ziziphumo zokushisa kwendawo ngexesha lenkqubo yokutofa.

Iimbangela zokutshiswa kwamanqaku

Amanqaku atshileyo anokubalelwa kwizinto ezininzi:

- Isantya sokutofa ngokugqithisileyo: Inaliti ekhawulezayo yeplastiki etyhidiweyo inokuvelisa ubushushu obugqithisileyo, okukhokelela kumanqaku okutsha.

- Ukupholisa okungonelanga: Ukupholisa okungonelanga kunokuvumela ubushushu ukuba buqokelele kwiindawo zendawo, kubangele iimpawu zokutsha.

- Ukuthotywa kweResin yezinto: Ezinye iintlaka zeplastiki zithandwa kakhulu ukuthotywa kwe-thermal, okukhokelela kumanqaku okutshisa.

I-Delamination: Ingxaki eLayered

I-Delamination ibhekiselele ekwahlulweni kweeleya ngaphakathi kwendawo ebunjiweyo. Ngokuqhelekileyo kubonakala njengemigca ebonakalayo okanye ukwahlukana, ukuphazamisa kokubili ukunyaniseka kwesakhiwo kunye nobuhle.

Iimbangela zeDelamination

I-Delamination ingenzeka ngenxa yoku:

- Ukuxubana kweMathiriyeli okungonelanga: Ukudibanisa kakubi kwezinto ngexesha lokubumba kunokubangela i-delamination.

- Ukungcoliseka kwezinto: Izinto ezingcolisayo ezifakwe ngexesha lokuphatha izinto okanye ukulungiswa kunokubangela ukuba iileya zihlukane.

- Ubushushu bokuNyibilika obunganelanga: Imimiselo yobushushu obungachanekanga bunokuba negalelo kwi-delamination.

Ukubhabha: Ingxaki yesantya

I-Jetting yinto apho isantya esiphezulu sezinto zeplastiki ezinyibilikisiweyo zichaphazela i-mold surface, ukudala imigca ebonakalayo okanye imigca kwindawo egqityiweyo. Ihlala ihambelana nokusetyenziswa kwezinto eziphezulu ze-viscosity.

Iimbangela zeJetting

I-Jetting inokuqalwa:

- Isantya esiphezulu sokutofa: Izantya zesitofu ezigqithisileyo zingakhokelela kwijetting, njengoko izinto eziphathekayo zichaphazela umphezulu wokungunda kunokuhamba kakuhle kwimingxuma.

- Uyilo lweSango: Uyilo lwesango olungafanelekanga lunokwandisa imiba ye-jetting.

Imigca Ehambayo: Indlela yokuNchasa okuncinci

Imigca ehambayo, eyaziwa ngokuba “imigca weld” okanye “imigca ezinithiweyo,” zidla ngokubonakala njengemigca engacacanga okanye iinduli kumphezulu wenxalenye. Zenzeka xa ukuhamba kwezinto zeplastiki ezityhidiweyo zidibana nokuchasana kwaye ziphinde zidibanise, zishiya i-seam ebonakalayo.

Iimbangela zeMizila eHambayo

Imigca ehambayo inokuvela:

- Ukupholisa izinto eziphathekayo: Ukwahluka kwimilinganiselo yokupholisa kunokubangela ukuba izinto ziqiniswe ngamaxesha ahlukeneyo, okukhokelela kwimigca yokuhamba.

- Inxalenye yeJiyometri entsonkothileyo: Amalungu anejometri ezintsonkothileyo okanye amasebe amaninzi achaphazeleka lula kwimigca yokuhamba.

Ubuchule bokuNciphisa isiphene

Ukunciphisa ezi ziphene kufuna indibaniselwano yoyilo, usetyenziso lwenkqubo, kunye nokukhethwa kwezinto:

- Ukuyilwa ngokutsha kweSango: Uyilo olululo lwesango kunye nokubekwa kunokunciphisa umngcipheko wamanqaku okutsha, i-delamination, kunye nejetting.

- Isantya sokutofa esilungiselelweyo: Lawula isantya sokutofa ukunqanda ukufudumeza kunye nejetting ngelixa uqinisekisa ukuhamba kwezinto ezifanelekileyo.

- Ukukhethwa kwezinto: Khetha imathiriyeli engafane yenzeke kakhulu ekutshisweni kwamanqaku kunye ne-delamination.

- Izixhobo kunye noyilo lokungunda: Sebenzisa utshintsho lwezixhobo kunye nokuphuculwa koyilo lokungunda ukunciphisa ukubakho kwemigca yokuhamba.

Inkungu: Inkungu yokungafezeki

Inkungu, edla ngokubizwa ngokuba “zinc” okanye “inkungu,” ibonakala ngathi kukho amafu okanye umphezulu omfiliba kwindawo ebunjiweyo. Esi siphene sinokuchaphazela kakhulu i-aesthetics yemveliso kunye nokucaca.

Oonobangela beNkungu

Inkungu ingenzeka ngenxa yoku:

- Ukungcoliseka kwezinto: Ungcoliseko olungeniswa ngexesha lokuphatha izinto okanye ukusetyenzwa lungakhokelela kwinkungu.

- Ukutshisa ngokugqithisileyo: Ukushisa okugqithisileyo ngexesha lenkqubo yokubumba kunokubangela ukuba izinto zihlaziywe, kubangele inkungu.

Amanqaku eSinki: Umngeni wokuNgenisa

Amanqaku e-sink kukudandatheka okanye ukungena kumphezulu wenxalenye ebunjiweyo. Zenzeka xa umphezulu wecandelo elijiyileyo lenxalenye liphola kwaye liqina kancinci kuneendawo zangaphakathi.

Iimbangela zamanqaku eSinki

Amanqaku e-sink anokubangelwa:

- Ukupholisa okungonelanga: Ukupholisa okungalinganiyo, ngakumbi kwiindawo ezityebileyo zenxalenye, kunokukhokelela kumanqaku okutshona.

- Ukuncipha kwezinto: Amazinga ahlukeneyo okucutheka ngaphakathi kwendawo angabangela amanqaku e-sink.

Weld Lines: Apho Materials Dibana

imigca weld, eyaziwa ngokuba “imigca ezinithiweyo,” Kwenzeka xa iiplastiki ezimbini okanye ngaphezulu ezinyibilikisiweyo zidibana kwaye ziphinda zihlangane ngexesha lenkqubo yokutofa. Le migca idla ngokubonakala kumphezulu wenxalenye egqityiweyo kwaye inokuchaphazela ingqibelelo yayo yesakhiwo.

Iimbangela zeWeld Lines

Imigca ye-weld inokwakheka ngenxa:

- Imiqobo yokuHamba kwezinto: Imiqobo okanye ijometri ngaphakathi kwesikhunta sinokubangela ukuba ukuhamba kwezinto kuhlukane kwaye kuhlangane kwakhona.

- Ukupholisa izinto eziphathekayo: Ukwahluka kwimilinganiselo yokupholisa kunokukhokelela ekubunjweni kwemigca ye-weld.

Imijelo: Amanqaku angabonakaliyo

Imijelo, njengoko igama labo libonisa, imigca ebonakalayo okanye imigca ebusweni benxalenye ebunjiweyo. Zinokubangelwa zizinto ezahlukeneyo kwaye zihlala zinzima ukuxilonga nokusombulula.

Izinto ezibangela imivimbo

Uluhlu lunokuvela:

- Ukungcoliseka kwezinto: Ukungcola okanye ukungcola kwizinto eziphathekayo kunokubangela imivimbo.

- Ukuxuba okungonelanga: Ukuxubana kakubi kwezinto eziphathekayo kunokukhokelela ekubunjweni kwe-streak.

Ubuchule bokuSombulula isiphene

Ukusombulula le mingeni kufuna indibaniselwano yoyilo, ukwenziwa kwenkqubo, kunye nolawulo lwemathiriyeli:

- Ubunyulu bezinto eziphathekayo: Qinisekisa ukuba izinto ezisetyenzisiweyo azinangcoliseko kunye nokungcola.

- UPhulo lokuPholisa: Lungiselela izicwangciso zokupholisa ukunciphisa umngcipheko weempawu zokucwila kunye nenkungu.

- Uphononongo loYilo lokungunda: Ngokuqhubekayo uphonononga uyilo lokubumba ukuchonga imithombo enokubakho yemigca ye-weld kunye nemivimbo.

- Ukukhethwa kwezinto: Khetha ngokucokisekileyo izixhobo ezinokuthi zifane ne-streak formation kunye nezinye iziphene.