Intshayelelo

Inkcazo yokuBunjwa kwesitofu esikhulu

Ukubumba inaliti enkulu kubhekiselele kwinkqubo yokwenziwa kokwenziwa kwezixhobo zeplastiki ezinobungakanani, ezo zingaphezulu kwee-intshi ezingama-24 kuwo nawuphi na umlinganiselo omnye. Kubandakanya ukutofwa kweplastiki enyibilikisiweyo kumngxuma wokungunda omkhulu kwaye yindlela eyimfuneko yokwenza iindawo ezininzi ezisetyenziswa kumacandelo awohlukeneyo.

Imbali emfutshane kunye ne-Evolution

Ukuqala ngophuhliso lomatshini wokuqala wokubumba inaliti ngeminyaka yoo-1870, itekhnoloji iye yavela kakhulu. Embindini wenkulungwane yama-20, imfuno yezinto ezinkulu zeplastiki zokusetyenziswa kwimizi-mveliso yakhuthaza ukukhula kwesitofu esikhulu sokubumba. Ukuqhubela phambili kwi-design ye-computer-aid (CAD), i-computer-aid-aid production (CAM), kunye nokuqaliswa koomatshini bokubumba inaliti ye-tonnage ephezulu kuye kwayiguqula le ndawo.

Ukubaluleka kweMveliso yale mihla

Ukubumba inaliti enkulu kubalulekile kumashishini afuna amandla aphezulu, alula, kunye namalungu antsonkothileyo. Inkqubo ibonelela ngokulinganisa okungahambelaniyo, ukuphinda-phinda, kunye nokusebenza kakuhle kwezinto, kuyenza ibaluleke kakhulu kwimveliso yanamhlanje.

ICandelo loku-1: Iziseko zokuBunjwa kwesitofu esikhulu

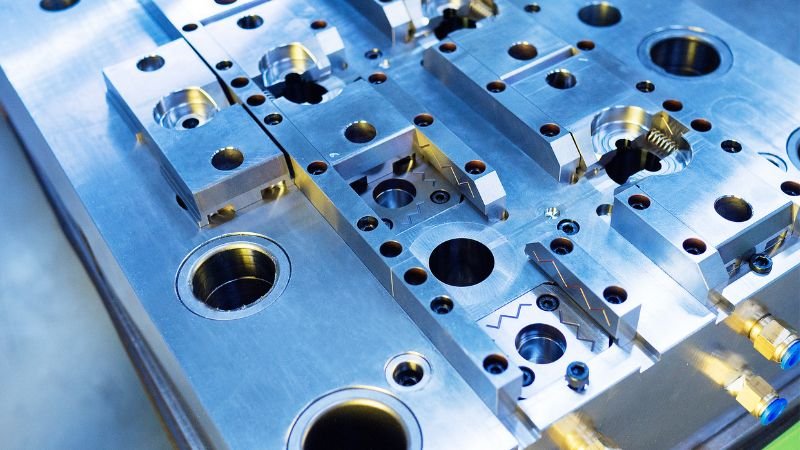

Inkqubo yokuMonda iTofo

Inkqubo iqala ngokutyisa i-granules zeplastiki kwi-barrel evuthayo, apho inyibilika khona. Isikrufu esibuyiselanayo okanye isitofu senkunzi yegusha ke sinyanzelela iplastiki enyibilikisiweyo kumngxuma wokungunda. Nje ukuba ipholile, inxalenye iyakhutshwa, kwaye umjikelo uqala ngokutsha. Le ndlela igqwesile ekuveliseni iinxalenye ezifanayo kwimiqulu ephezulu kunye nenkunkuma encinci.

Umgangatho vs. Isikali esikhulu

Ngokungafaniyo ukubumba isitofu esisemgangathweni, oomatshini abakhulu bokubumba iinaliti basebenza ngamandla amakhulu okubamba—ngokufuthi bedlula iitoni ezili-1000. Ziyakwazi ukuhlalisa ubungakanani obukhulu bokungunda kwaye zikwazi ukutofa imathiriyeli yeplastiki enobungakanani bokudutyulwa ukuya kuthi ga kumakhulu eeponti ubunzima.

Isishwankathelo seZixhobo

Oomatshini abakhulu bokubumba benaliti baxhotyiswe ngeempawu eziphambili ezifana neenkqubo zokulawula ezichanekileyo, iiyunithi ezininzi zokutofa ngokudibeneyo, kunye neenkqubo zokupholisa eziphuculweyo zokupholisa inxalenye efanayo. Aba matshini bakhethekileyo babaluleke kakhulu kwimveliso eyimpumelelo yamacandelo amakhulu.

Icandelo lesi-2: Izixhobo kunye noYilo lokuBunjwa kwesitofu esikhulu

Iintlobo zezinto eziphathekayo

I-Polycarbonate, i-polyamide, kunye ne-high-impact polystyrene ziphakathi kwezinto ezininzi ezifanelekileyo kwimveliso enkulu. Ezi zixhobo zikhethwa ngenxa yamandla azo, ukuxhathisa kwe-thermal, kunye nokugqiba umgangatho.

Iimpahla zeMathiriyeli

Iipropathi zemathiriyeli eziphambili ezinjengokwandiswa kwe-thermal, ukuxhathisa ukurhubuluza, kunye namandla okuqina kubaluleke kakhulu kwimveliso enkulu yokuqinisekisa ukuzinza kunye nokusebenza kumjikelo wobomi bayo bonke.

Iingqwalasela zoyilo

Uyilo lokwenziwa kokwenziwa kwinaliti enkulu yokubumba kufuneka ijongane nemingeni yokuncipha, i-warpage, kunye noxinzelelo loxinzelelo. Abaqulunqi bahlala besebenzisa isoftware yohlalutyo lokuhamba ukuqikelela nokunciphisa le miba.

Icandelo lesi-3: Oomatshini bokuBumba bokuTofa okukhulu

Iinkcukacha zoomatshini

Oomatshini abaneetoni eziphezulu ezisetyenziselwa ukubumba inaliti enkulu baneempawu ezithile ezinje ngeesilinda ezineekhareji ezimbini zokuhambisa amandla afanayo kunye nokwanda kobungakanani beplaten ukulungiselela ukubumba okukhulu.

Amandla okuQhaphaza

Amandla okubamba ama-molds amakhulu anokuqala ukusuka kwi-1000 ukuya kwi-6000 yeetoni okanye ngaphezulu, okubaluleke kakhulu ukuchasana noxinzelelo olunzima lwenaliti olufunekayo ukuze ugcwalise kwaye upakishe umngxuma wokungunda ngokufanelekileyo.

Imiboniso eyodwa

Oomatshini be-tie-bar-less banika ukuguquguquka okukhulu kubungakanani bokubumba kunye nokulula kokutshintsha ngundo. Iiplaten ezijikelezayo zikwasetyenziselwa ukusetyenziswa kwamacandelo amaninzi, ukuvumela ukuhlanganiswa kwezinto ezahlukeneyo zibe yindawo enye enkulu.

Icandelo 4: IiParameters zeNkqubo kunye noPhuculo

Ukumisela iiParameters

Iiparamitha zenkqubo ekubunjweni kwenaliti enkulu, efana nobushushu obunyibilikayo, isantya senaliti, uxinzelelo lwangasemva, kunye nexesha lokupholisa, zibalulekile ekuchazeni umgangatho wenxalenye yokugqibela kwaye kufuneka ilungiswe ngobunono kwimveliso nganye.

Imiceli mngeni kuScaling

Ukuqinisekisa ukuhamba okunyibilikayo okungaguqukiyo kunye nokugcina imfezeko yolwakhiwo kuya kuba nzima ngakumbi njengoko ubungakanani benxalenye bukhula. Inkqubela phambili kwitekhnoloji yokulinganisa inkqubo inceda ukujongana nale mingeni ngaphambi kwemveliso eyiyo.

Ukuqinisekisa umgangatho

Ekubunjweni kwenaliti enkulu, iindlela zovavanyo ezingonakalisi, ezinje nge-ultrasonic kunye ne-x-reyi, zihlala zisetyenziswa emva kokuvelisa ukuvavanya ubume bangaphakathi bamalungu kunye nokuqinisekisa ukuba bayahlangabezana nemigangatho engqongqo yobulunga.

Icandelo lesi-5: Ukusetyenziswa kokuBunjwa kwesitofu esikhulu

Ukusetyenziswa koShishino

Umzi-mveliso weemoto usebenzisa isitofu esikhulu sokubumba ukuvelisa iindawo ezifana neebhampa, iideshibhodi, kunye neepaneli zocango. Kwi-aerospace, isetyenziselwa amacandelo ekhabhinethi kunye nezinto zesakhiwo. Ushishino lwezixhobo luxhomekeke kule teknoloji kwiipaneli kunye neengxenye zesakhiwo seefriji kunye noomatshini bokuhlamba.

Izifundo

Imizekelo ibandakanya ukusetyenziswa kwe-injection enkulu ye-injection kwicandelo leemoto ukunciphisa ubunzima bezithuthi ngokudibanisa ama-composites aphezulu, okubangele ukusebenza kakuhle kwamafutha kunye nokunciphisa ukukhutshwa.

Icandelo lesi-6: Izinto eziluncedo kunye nemida

Izinto eziluncedo kwezoQoqosho

Ukukwazi ukuvelisa iinxalenye ezinkulu ngomthamo ophezulu kunye nomgangatho ohambelanayo uguqulela kwiinzuzo ezinkulu zoqoqosho, kubandakanywa iindleko ezincitshisiweyo zabasebenzi kunye nokwanda kwemveliso.

Ukuqwalaselwa kokusingqongileyo

Iinzame zozinzo ekubumbeni isitofu esikhulu zijolise ekunciphiseni inkcitho kunye nokusetyenziswa kwamandla. Ukusetyenziswa kwe-bioplastics kunye nezicwangciso zokurisayikilishwa zisenyuka ukunciphisa impembelelo yokusingqongileyo.

Ukulinganiselwa

Ngaphandle kwezibonelelo zayo, ukubumba inaliti enkulu kuzisa imingeni efana neendleko eziphezulu zotyalo-mali lokuqala, imfuno yeendawo ezinkulu zokuvelisa, kunye nemfuno yothutho olukhethekileyo lwamalungu amakhulu.

Icandelo lesi-7: Inguqulelo neTekhnoloji

Uphuculo lweTekhnoloji yoomatshini

Izinto ezintsha zamva nje ziquka oomatshini bokubumba inaliti yombane, enika amandla amakhulu kunye nokuchaneka okuthe kratya xa kuthelekiswa noomatshini behydraulic.

Ukuzenzekela kunye neRobhothi

Ukuzenzekelayo, ngokusetyenziswa kweerobhothi, kuye kwavumela ukuchaneka okukhulu ekuphatheni nasekunciphiseni iindawo ezinkulu ezibunjiweyo, okubangelwa ukwanda kokusebenza kunye nokhuseleko.

Isoftware kunye nokulinganisa

Ukuqhubela phambili kwisoftware yohlalutyo lokuhamba kwe-mold kuvumela ukuqikelelwa kunye nokunciphisa imiba enokubakho ngexesha lesigaba soyilo, ukunciphisa kakhulu ixesha kunye neendleko ezinxulumene nolingo kunye nempazamo.

ICandelo lesi-8: IiNdlela zokuSebenza eziBalaseleyo kunye neziFundo zeMizekeliso

Ezona Sebenziso ziFanelekileyo

Ukwamkela indlela yokuvelisa ebhityileyo, iishedyuli zololongo rhoqo, kunye nokubandakanya itekhnoloji yokonga amandla ngundoqo kwimisebenzi esebenzayo yokubumba inaliti enkulu.

IiNkokheli zoShishino

Iinkampani ezifana ne-Husky Injection Molding Systems kunye ne-Engel zisete iibenchmarks zeshishini kwimveliso yenxalenye enkulu, zihlala zisenza izinto ezintsha kwintsimi.

Ukuqukumbela

Ikamva elizayo

Ukudityaniswa kwemathiriyeli emitsha kunye nenkqubela phambili yetekhnoloji eqhubekayo iqikelela ikamva elomeleleyo lokubumba inaliti enkulu, enokubanakho ukukhula kumashishini ahlukeneyo.

Iingqwalasela zoLawulo

Isishwankathelo semithetho yehlabathi echaphazela ukubumba okukhulu kwesitofu, okufana nokuthotyelwa kwe-REACH eYurophu kunye nezikhokelo ze-EPA e-United States, ziya kubandakanywa.