Intshayelelo

I-Epoxy Resin, eyaziwa ngamandla ayo kunye nokuguquguquka kwayo, izibini ngokungenamthungo kunye nenkqubo yokubumba inaliti. Xa zidityanisiwe, kwenziwa iplastiki eyomeleleyo, ehlala ihleli, ilungele uluhlu olukhulu lwezicelo zemizi-mveliso. Lo mbutho awuqinisekisi nje kuphela ukuveliswa komgangatho ophezulu, iimveliso ezinokomelela kodwa ukwahlangabezana neemfuno ezichanekileyo kunye nokungaguquguquki kumacandelo awohlukeneyo. Ngala macandelo alandelayo, siza kuphonononga uhambo olunika umdla lwe-epoxy resin, ukusebenzisana kwayo nokubumba inaliti, kunye neengenelo ezimangalisayo eziziswa yile ntsebenziswano kumhlaba wemveliso wale mihla.

Ukusetyenziswa ngokwembali kwe-Epoxy Resin

Iingcambu ze-epoxy resin zibuyela emva kwi-1930s, kunye nokusetyenziswa okuphawulekayo kweentyantyambo kwi-1940s ye-prosthetics yamazinyo ngenxa yentsebenziswano ekhuselekileyo kunye nezicubu zomntu. Uhambo lwayo luye lwanda kuwo wonke amacandelo afana neenqwelomoya, iimoto, kunye nolwakhiwo, ngenxa yeempawu zayo zokuncamathelisa ezibalaseleyo kunye nokumelana nomhlwa. Ukutsiba okubalulekileyo yayikukusebenza kwayo kwi-aerospace yokwenza izinto ezikhaphukhaphu kodwa ezomeleleyo zenqwelomoya. Ukutyhubela amashumi eminyaka, ukuguquguquka kwe-epoxy resin kuye kwanda ngokuqhubekayo, ukufumana indawo yayo kwizicelo ezininzi, ukubeka isiseko esiluqilima somdibaniso kunye netekhnoloji yokubumba inaliti.

IKhemistri ngasemva kwe-Epoxy Resin

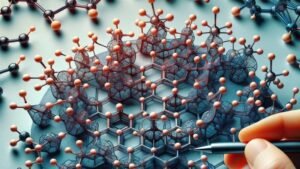

I-Epoxy resin idume ngeempawu zayo ezoyikisayo, kwaye ikhredithi ubukhulu becala iya kubume bayo beekhemikhali ezizodwa. Embindini we-epoxy resin kukho i-polymer ye-thermosetting, eyahlulwa ngamatyathanga ayo emolekyuli adityanisiweyo. Nantsi into elula yokujonga kwikhemistri enika amandla epoxy resin.

Ulwakhiwo lweemolekyuli

I-epoxy resin iquka iimolekyuli kunye neqela le-epoxide, isakhiwo esisebenzayo esinesangqa. Ubukho beli qela le-epoxide libaluleke kakhulu njengoko lenza ukuba i-resin iphendule ngeendlela ezahlukeneyo zokuphilisa okanye i-hardeners, iququzelele inkqubo yokudibanisa i-cross-link eyona nxalenye ye-epoxy resin's robustness.

Inkqubo yokuhlanganisana

Xa i-epoxy resin isebenzisana ne-hardener, i-chemical reaction ilandela, ekhokelela ekubunjweni kweebhondi ezidibeneyo phakathi kweentambo ze-molecular zombini iikhompawundi. Le nkqubo ye-cross-linking iguqula i-liquid epoxy resin kunye ne-hardener mixer ibe yinto eqinile, engaguqukiyo. Isiphumo sothungelwano oluqhagamshelwe ngokunqamlezileyo lunika i-epoxy resin kunye namandla ayo ophawu, ukuqina, kunye nokuchasana nezinto ezisingqongileyo.

IiPropati eziSebenzayo

Inkalo ephawulekayo ye-epoxy resin's chemistry kukunyaniseka kwayo. Ngokutshintsha iintlobo kunye nomlinganiselo wee-resins kunye ne-hardeners, okanye ngokuzisa izongezo, i-mechanical and thermal properties of the resultat material inokulungiswa kakuhle. Oku kuguquguquka kuvula uluhlu olubanzi lwezinto ezinokwenzeka, ukwenza i-epoxy resin iqhelane neemfuno ezithile kuzo zonke izicelo ezahlukeneyo.

I-Epoxy Resin kwi-Injection Molding

Ukudityaniswa kweresin ye-epoxy enenaliti yokubumba ixela umanyano lwamandla kunye nokuchaneka, umxube onceda ekudaleni izinto ezihlala ixesha elide nezichanekileyo. Eli candelo lityhila inkqubo yokudibanisa i-epoxy resin kwi-injection yokubumba kunye neziphumo ezihle.

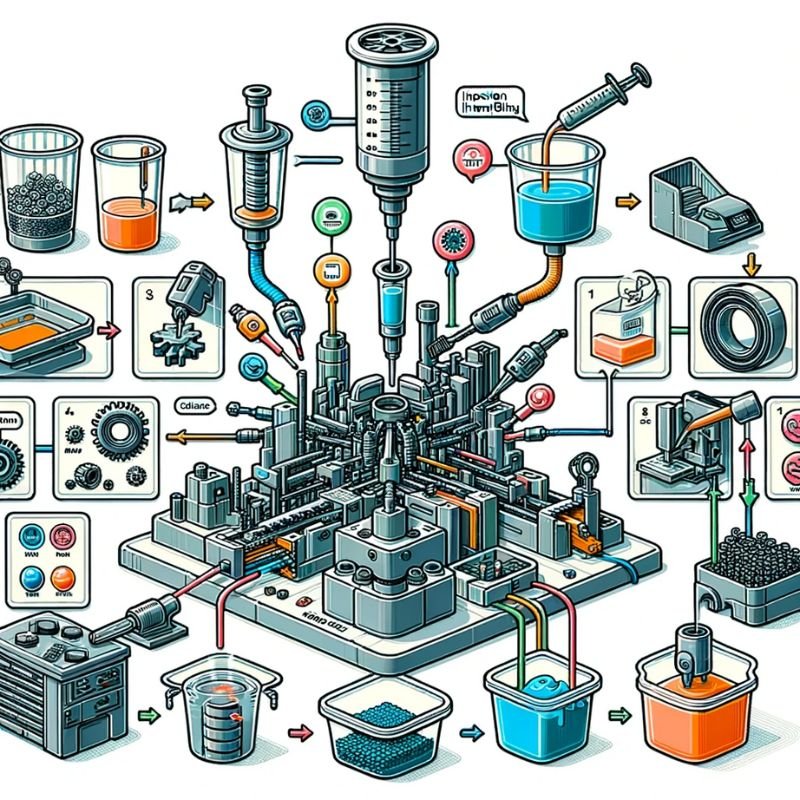

Inkqubo

Kumjikelo wokubumba wenaliti eqhelekileyo, i-epoxy resin, ecaleni kwe-hardener yayo, yondliwa kumbhobho oshushu apho ifikelela kwimo enyibilikayo. Lo mxube uthi ke utofwe kumgodi wokungunda phantsi koxinzelelo oluphezulu. Njengoko i-concoction ihlala ngaphakathi kokungunda, iqalisa inkqubo yokunyanga, isuka kulwelo ukuya kwimeko eqinileyo njengoko i-cross-linking reaction iqhubeka. Emva kokuba sele iphelile, ukungunda kuyavulwa, kwaye inxalenye egqityiweyo iyakhutshwa, ilungele ukuqalisa uhambo lwayo lokusebenza.

Iingenelo Zityhiliwe

I-tryst ye-epoxy resin enenaliti yokubumba ayisiyonkqubo nje; lisango lokungena kummandla weenzuzo:

- Ukomelezwa koKuhlala: Ikhemikhali edibanisa i-cross-link ye-epoxy resin izipho iimveliso ezibunjiweyo ezinokuqina okuphezulu. Ziyakwazi ukumelana nokuguga, ukubola, kunye nobunzima bemekobume, ziqinisekisa ubomi obude naphantsi kweemeko ezinzima.

- Ukwenza okuphezulu: Ukuchaneka okuhambelana nokubumba inaliti, kunye namandla e-epoxy resin, kuvelisa iimveliso ezibonisa ukusebenza okuphezulu. Ukukwazi kwabo ukugcina ingqibelelo phantsi koxinzelelo kubenza bafanelekele izicelo ezibalulekileyo.

- Iindleko-zobuchule: Ngelixa iindleko zangaphambili zinokubonakala ngathi zininzi, ukusebenza kweendleko zexesha elide kuyaphawuleka. Ubomi obude kunye neemfuno zokugcinwa okuphantsi kweemveliso ezibunjiweyo ze-epoxy resin zinciphisa utyalo-mali lokuqala, zinika ukhetho olungabizi kakhulu ekuhambeni kwexesha.

- Ukuguquguquka koyilo: Ukuguquguquka kweempawu ze-epoxy resin kunye nokuchaneka kwesitofu sokubumba kunika ububanzi boyilo olubanzi. Oku bhetyebhetye kubalulekile ekulungiseleleni iimfuno ezahlukeneyo zamashishini ahlukeneyo, ukusuka kwiimoto ukuya kwi-elektroniki.

Ukusetyenziswa kweeMveliso ze-Epoxy Resin ezibunjiweyo

Ukudityaniswa kweresin ye-epoxy kunye nokubunjwa kwenaliti kuvule indlela yezigidigidi zezicelo kumacandelo awohlukeneyo. Eli candelo likhanyisa uluhlu olubanzi lweemveliso eziphuma kolu manyano, kunye namashishini anempembelelo enkulu.

| Ishishini | Imizekelo yosetyenziso |

|---|---|

| Imizi-mveliso | Iigiya, iibheringi, amacandelo olwakhiwo |

| Ezombane | Ukufakwa kunye nokukhuselwa kwezinto ze-elektroniki |

| Iimoto | Iicasings, izindlu, iindawo zesakhiwo |

| Ukwakhiwa | Ukudibanisa kunye ne-ankile izakhi zesakhiwo |

| I-Aerospace | Ulwakhiwo lwamalungu alula kodwa omelele |

| Ukutya & Isiselo | Izikhongozeli ezomeleleyo kunye nezixhobo |

| Owaselwandle | Amacandelo esakhiwo, iingubo zokukhusela |

Ukuqhubela phambili kwiTekhnoloji ye-Epoxy Resin

Itekhnoloji yetekhnoloji ye-epoxy resin yenye yendaleko engaguqukiyo, ngakumbi kumanyano lwayo kunye nokubumba inaliti. Eli candelo lichaza inkqubela phambili yamva nje ephucula ukuhambelana kwe-epoxy resin kunye nenaliti yokubumba, ekhokelela kwiimveliso eziphezulu.

Iifomyula eziphuculweyo

Iminyaka yamva nje ibone uphuhliso lwe-epoxy resin formulations ejolise ekuphuculeni ukusetyenzwa lula kunye neempawu zemveliso yokugqibela. Le mixube ilungiselelwe ukuhlangabezana neemfuno ezithile ezifana nokuhamba okuphuculweyo, ukuncitshiswa kwexesha lokunyanga, kunye neempawu eziphuculweyo ze-thermal okanye zomatshini.

I-Nanotechnology

Ukuhlanganiswa kwe-nanotechnology kunye ne-epoxy resin yinto ebalulekileyo yokutsiba phambili. Ngokubandakanya i-nanoparticles, i-mechanical, thermal, kunye ne-barrier properties of molded epoxy resin products zandiswa kakhulu ngaphandle kokuphazamisa inzuzo yendalo ye-epoxy resin.

Imveliso eyongezelelweyo

I-cross-pollination yetekhnoloji ye-epoxy resin kunye nemveliso eyongezelelweyo okanye i-3D yokushicilela ivula iindlela ezintsha. Le synergy ivumela ukuveliswa kokubumba okuntsokothileyo, okuchaneke kakhulu kokubumba inaliti, ukunciphisa amaxesha okukhokela, kunye nokuvumela ubuchule bokuyila obuntsonkothileyo.

IiResins ze-Epoxy ezizinzileyo

Kwilinge lokulungelelanisa neenjongo zokuzinza kwihlabathi jikelele, uphuhliso lwe-bio-based epoxy resins lufumana amandla. Ezi resins zithathwe kwizibonelelo ezivuselelekayo, ziphawula inyathelo lokunciphisa i-carbon footprint yemveliso ye-epoxy resin kunye nokusetyenziswa.

IiResins ze-Epoxy ezihlakaniphile

Ukuqaliswa kwe-smart epoxy resins ekwazi ukuziphilisa okanye ukutshintsha izakhiwo ekuphenduleni ukuvuselela kwendalo kuyinkqubela ephawulekayo. Ezi resins zivelisa isithembiso sokwandisa ubomi kunye nokusebenza kweemveliso ezibunjiweyo.

Ubuchwephesha boNyango oluPhezulu

Itekhnoloji entsha yokunyanga iyavela ukukhawulezisa inkqubo yokunyanga i-epoxy resin kwizicelo zokubumba inaliti. Ezi nkqubela phambili zibalulekile ekwandiseni impumelelo yemveliso kunye nomgangatho wemveliso.

Inkalo yozinzo

Kwihlabathi eliya lisiya lisiya kuqheliselo oluzinzileyo, i-epoxy resin kunye nenaliti yokubumba i-nexus ayilibazisi. Eli candelo linika ukukhanya kwiimpembelelo zendalo esingqongileyo kunye nomgama osingise kuzinzo kulo mmandla.

| Umba | Inkcazo |

|---|---|

| Impembelelo yokusingqongileyo | Iiresin ze-epoxy zemveli ezivela kwi-petrochemicals zenza imingeni yokulahla. |

| I-Bio-based Epoxy Resins | I-epoxy resins evela kwimithombo ehlaziyiweyo enciphisa impembelelo yokusingqongileyo. |

| Ukurisayikilisha iinguqulelo ezintsha | Ubuchule bokurisayikilisha bemichiza buphucula ukuphinda kusetyenziswe imveliso ye-epoxy resin. |

| Ukusebenza kakuhle kwamandla kwiMveliso | Izenzo zokonga amandla ekubumbeni inaliti yokunciphisa ukusetyenziswa kwamandla. |

| UkuNcitshiswa kweNkunkuma | Inkcitho yemathiriyeli encinci ekubumbeni inaliti inegalelo kuzinzo. |

| Izongezo ze-Eco-friendly | Ukudityaniswa kwezongezo ze-eco-friendly ezihambelana nokuqwalaselwa kokusingqongileyo. |

Ukuqukumbela

Intsebenziswano phakathi kwe-epoxy resin kunye nenaliti yokubumba ivule indlela yokuqina, iimveliso ezisebenza kakhulu kumacandelo amaninzi. Ukusuka kwimvelaphi yayo yembali ukuya kwizicelo zanamhlanje kunye nezenzo zozinzo lokucinga phambili, le synergy ibonisa uhambo olumangalisayo lokusungula izinto ezintsha. Njengoko itekhnoloji ihambela phambili, umanyano lwe-epoxy resin kunye nenaliti yokubumba iyaqhubeka nokuthembisa ikamva lokwenziwa kwemveliso ephuculweyo, ukutyhala imida kwisayensi yezinto eziphathekayo ngelixa ichaza ukuzinikela okuqinileyo kuzinzo lokusingqongileyo.