Ever found yourself staring at plastic products and wondering, “What’s the deal with LDPE and HDPE?” Don’t worry, you’re not alone. These two plastic superstars, Low-Density Polyethylene (LDPE) and High-Density Polyethylene (HDPE), are everywhere you look, from your trusty plastic bag to water pipes that keep your showers running.

In this easygoing guide, we’re diving deep into LDPE and HDPE. Think of it as a friendly chat about plastic cousins who may look alike but have some interesting secrets up their polymer sleeves. We’ll unlock the mysteries of their molecular structures, chat about their physical and chemical traits, spill the beans on how they’re made, and even snoop around to find out where they’re hanging out the most.

So, if you’ve ever been curious about what makes these plastics tick and why they matter, stick around. By the time we’re done, you’ll be the resident plastic guru among your friends. Let’s embark on this plastic adventure and uncover the fascinating world of LDPE vs. HDPE!

Composition and Molecular Structure

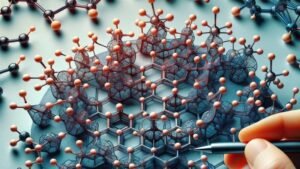

To comprehend the dissimilarities between LDPE and HDPE, it is imperative to begin with the fundamentals: their composition and molecular structure.

| Property | LDPE (Low-Density Polyethylene) | HDPE (High-Density Polyethylene) |

|---|---|---|

| Polymerization Process | Radical polymerization | Ziegler-Natta polymerization |

| Molecular Structure | Branched | Linear |

| Density (g/cm³) | 0.91 – 0.94 | 0.94 – 0.97 |

| Flexibility | Highly flexible | Less flexible, more rigid |

LDPE: LDPE is created through radical polymerization, resulting in a molecular structure characterized by branching and lower density. The branching of polymer chains makes LDPE flexible and less dense compared to HDPE.

HDPE: HDPE is produced via Ziegler-Natta polymerization, yielding a linear and highly structured molecular arrangement. The absence of branching in HDPE chains imparts a higher density and greater rigidity.

Physical Properties

The physical properties of LDPE and HDPE are a direct consequence of their distinct molecular structures. Let’s delve into these properties to better understand how LDPE and HDPE differ in terms of density, strength, flexibility, transparency, and temperature resistance.

| Property | LDPE | HDPE |

|---|---|---|

| Molecular Structure | Branched | Linear |

| Density (g/cm³) | 0.91 – 0.94 | 0.94 – 0.97 |

| Flexibility | Highly flexible | Less flexible, more rigid |

| Chemical Resistance | Good resistance to many chemicals | Exceptional chemical resistance |

| Water Resistance | Resistant to moisture | Highly resistant to moisture |

| UV Resistance | Sensitive to UV radiation | More UV-resistant |

| Strength and Durability | Lower tensile strength and rigidity | Excellent tensile strength and durability |

| Recyclability | Recyclable but less commonly recycled | Highly recyclable |

LDPE’s flexibility and lightweight nature make it ideal for packaging, while HDPE’s strength and durability make it suitable for structural and industrial uses.

Chemical Properties

| Property | LDPE | HDPE |

|---|---|---|

| Chemical Resistance | Good resistance to many chemicals, acids, bases, and organic solvents | Exceptional chemical resistance, resistant to a wide range of chemicals including corrosive acids, alkalis, and hydrocarbons |

| Water Resistance | Resistant to moisture | Highly resistant to moisture |

| UV Resistance | Sensitive to UV radiation | More UV-resistant |

| Temperature Range | Moderate temperature stability with a melting point typically ranging from 105 to 115°C (221 to 239°F) | Higher temperature stability with a melting point usually between 120 and 130°C (248 to 266°F) |

LDPE’s resistance to a variety of chemicals makes it suitable for packaging and laboratory applications, while HDPE’s exceptional chemical resistance makes it a top choice for applications involving harsh chemicals and outdoor exposure.

Manufacturing Process

The process by which LDPE and HDPE are manufactured plays a significant role in determining their properties and, subsequently, their suitability for various applications.

LDPE Manufacturing

- Ethylene Polymerization: LDPE is produced by radical polymerization, where ethylene molecules are polymerized under relatively low pressure and temperature conditions. This results in a highly branched and low-density polymer structure.

- Initiators and Catalysts: Initiators and catalysts are used to initiate the formation of polymer chains from the ethylene monomers.

- Chain Branching: LDPE polymerization leads to the branching of polymer chains, creating a web-like structure that imparts flexibility.

- Cooling and Solidification: After polymerization, LDPE is cooled and solidified into the desired form, such as pellets or sheets, for further processing.

HDPE Manufacturing

- Ethylene Polymerization: HDPE begins with the polymerization of ethylene monomers under high pressure and temperature conditions.

- Catalysts: Specialized catalysts are employed to control the polymerization reaction and create linear, high-density chains.

- No Branching: HDPE production results in a linear, highly structured molecular arrangement with no branching.

- Cooling and Processing: After polymerization, HDPE is cooled and processed into various forms, including pellets, pipes, and sheets.

It’s important to note that the manufacturing processes for LDPE and HDPE differ significantly, leading to distinct molecular structures and, consequently, varying physical and chemical properties. LDPE’s branched structure results in flexibility, while HDPE’s linear structure provides strength and rigidity.

Common Applications

LDPE and HDPE may share the same polymer base, but their unique properties make them suitable for distinct applications across various industries.

LDPE Applications

- Plastic Bags: LDPE’s flexibility and moisture resistance make it a popular choice for manufacturing disposable plastic bags used for grocery shopping, packaging, and storage.

- Squeeze Bottles: LDPE’s ease of molding and squeezability make it ideal for packaging products like shampoo, condiments, and other liquids.

- Food Packaging: LDPE is commonly used in food packaging materials, including cling film, sandwich bags, and freezer bags, due to its non-reactive nature and moisture resistance.

- Agricultural Films: Its UV resistance and durability make LDPE suitable for agricultural applications, such as greenhouse covers and mulch films.

- Medical and Laboratory Equipment: LDPE’s chemical resistance and ease of sterilization make it suitable for items like laboratory containers, disposable gloves, and medical tubing.

HDPE Applications

- Water and Gas Pipes: HDPE’s strength and durability make it an excellent choice for water and gas distribution pipes, as it can withstand high-pressure systems and resist corrosion.

- Milk Jugs and Detergent Bottles: HDPE’s robustness and resistance to chemicals make it suitable for packaging milk, detergent, and other household products.

- Trash Bags: HDPE’s toughness and puncture resistance make it ideal for manufacturing heavy-duty trash bags and liners.

- Industrial Containers: HDPE drums and containers are commonly used for storing and transporting chemicals, lubricants, and hazardous materials.

- Playground Equipment: Its UV resistance and durability make HDPE a preferred material for outdoor playground equipment, ensuring safety and longevity.

- Geomembranes: HDPE geomembranes are used in construction and environmental applications for waterproofing and containment of liquids.

These applications showcase the versatility of LDPE and HDPE in meeting a wide range of requirements in our daily lives and various industries. Whether it’s the convenience of LDPE in packaging or the strength of HDPE in infrastructure, these plastics play pivotal roles in modern society.

Advantages and Disadvantages

While LDPE and HDPE each offer a set of unique properties that make them suitable for various applications, it’s important to consider their advantages and disadvantages to make informed choices in selecting the right material.

Advantages of LDPE

- Flexibility: LDPE is highly flexible and easily conformable, making it ideal for applications requiring stretchability and resilience.

- Ease of Processing: LDPE is easy to process through methods such as extrusion and blow molding, which makes it cost-effective for manufacturing various products.

- Chemical Resistance: LDPE exhibits good resistance to many chemicals, making it suitable for packaging liquids and powders and for use in laboratory equipment.

- Moisture Resistance: LDPE is resistant to moisture and can be used in applications where moisture or humidity is a concern.

- Lightweight: LDPE is relatively lightweight, making it a practical choice for products where weight is a consideration.

Disadvantages of LDPE

- Lower Strength: LDPE has lower tensile strength and rigidity compared to HDPE, limiting its suitability for certain structural applications.

- UV Sensitivity: LDPE is sensitive to UV radiation and can degrade when exposed to prolonged sunlight, which restricts its outdoor use.

Advantages of HDPE

- Strength and Durability: HDPE is exceptionally strong and durable, with excellent tensile strength, making it suitable for structural and heavy-duty applications.

- Chemical Resistance: HDPE’s high chemical resistance makes it ideal for applications involving exposure to corrosive chemicals and solvents.

- Water Resistance: HDPE is highly resistant to moisture and water, making it a reliable choice for water-related applications.

- UV Resistance: HDPE is more UV-resistant than LDPE, allowing it to withstand outdoor exposure without significant degradation.

- Recyclability: HDPE is widely recyclable and can be turned into various new products, promoting environmental sustainability.

Disadvantages of HDPE

- Rigidity: HDPE is less flexible than LDPE, which can limit its use in applications where flexibility is essential.

- Processing Complexity: HDPE may require more specialized processing techniques due to its higher melting point and rigidity.

- Heavier Weight: HDPE is denser and heavier than LDPE, which may impact transportation and handling costs.

Choosing between LDPE and HDPE depends on the specific requirements of your application. LDPE’s flexibility and ease of processing are advantageous for packaging, while HDPE’s strength and durability make it suitable for structural and industrial uses.

Environmental Impact

As global attention on environmental sustainability grows, evaluating the environmental impact of materials like LDPE and HDPE becomes crucial.

Environmental Impact of LDPE

- Recyclability: LDPE is recyclable, but it may be less commonly recycled compared to some other plastics. The recycling process typically involves melting and re-extruding the material to create new products.

- Waste and Litter: LDPE products like plastic bags can contribute to litter and environmental pollution when not properly disposed of or recycled.

- Energy Consumption: The production of LDPE requires energy, and the extraction of the raw material, ethylene, is energy-intensive. However, LDPE’s relatively low processing temperature can mitigate some energy-related concerns.

- Biodegradability: LDPE is not readily biodegradable, which means it can persist in the environment for a long time if not properly managed.

Environmental Impact of HDPE

- Recyclability: HDPE is highly recyclable and is one of the most commonly recycled plastics. It can be used to create a wide range of products, including new containers and pipes.

- Reduced Environmental Impact: The recycling process for HDPE consumes less energy compared to the production of virgin HDPE, making it an environmentally favorable option.

- Durability: HDPE’s durability and resistance to degradation ensure that products made from it have longer lifespans, reducing the need for frequent replacement and waste.

- Biodegradability: Similar to LDPE, HDPE is not biodegradable under typical environmental conditions.

Both LDPE and HDPE can be recycled, but HDPE has a stronger track record for recycling due to its higher demand and the ease with which it can be processed into new products. Additionally, HDPE’s durability and resistance to UV radiation can contribute to extended product lifetimes, reducing the overall environmental impact.

Conclusion

In the realm of plastics, LDPE and HDPE stand as two distinct yet versatile members of the polyethylene family. Understanding their differences and applications is crucial for industry professionals and consumers alike.

LDPE, with its flexibility, finds use in plastic bags, bottles, and food packaging. However, its susceptibility to UV degradation limits its outdoor use.

HDPE, known for its strength and durability, is the choice for water and gas pipes, industrial containers, and more. Its recyclability and extended product lifespans contribute to environmental advantages.

In an era marked by environmental concerns, both LDPE and HDPE offer recyclability options, with HDPE having a stronger recycling infrastructure. Recycling, reducing single-use plastics, and responsible disposal are steps toward a sustainable future.

References

- The Plastics Division of the American Chemistry Council. (2021). Types of Plastics. Retrieved from https://plastics.americanchemistry.com/Types-of-Plastics/

- Brydson, J. A. (1999). Plastics Materials (7th ed.). Butterworth-Heinemann.

- Callister, W. D. (2006). Materials Science and Engineering: An Introduction (7th ed.). John Wiley & Sons.

- ASTM International. (2021). ASTM D4976 – 20 Standard Specification for Polyethylene Plastics Molding and Extrusion Materials. Retrieved from https://www.astm.org/Standards/D4976.htm

- ASTM International. (2021). ASTM D3350 – 20 Standard Specification for Polyethylene Plastics Pipe and Fittings Materials. Retrieved from https://www.astm.org/Standards/D3350.htm

- European Plastics Converters. (2021). Polyethylene (PE). Retrieved from https://euromap.org/polyethylene-pe/