Polivinil klorid ali na kratko PVC je očarljiv sintetični material, ki je postal nepogrešljiv del našega vsakdanjega življenja. Od cevi, ki nosijo vodo v naših domovih, do reševalnih medicinskih pripomočkov v bolnišnicah in celo električnih kablov, ki poganjajo naše naprave, ima PVC ključno vlogo pri neštetih aplikacijah. V tem poglobljenem vodniku bomo raziskali svet PVC, razkrili njegov izvor, razumeli njeno kemijo, odkrili njegove različne vrste in se potapljali v številni uporabi. Razpravljali bomo tudi o vidikih okolja, zdravja in varnosti, pa tudi o prihodnosti tega vsestranskega gradiva.

Kratka zgodovina PVC

Zgodba o PVC se začne z privlačno zgodovino odkritja in inovacij. Pojdimo na hitro pot nazaj v čas, da raziščemo, kako je nastalo ta neverjetni material.

Zgodnji poskusi z vinilnim kloridom: Korenine PVC lahko zasledimo do zgodnjega 19. stoletja, ko so kemiki začeli eksperimentirati z vinilnim kloridnim plinom. Vendar je bil napredek počasen, resnični potencial te spojine pa je desetletja ostal neizkoriščen.

Pojav v 20. stoletju: Šele v začetku 20. stoletja se je PVC začel oblikovati kot uspešen material. Leta 1912 je Fritz Klatte, nemški kemik, prvič uspešno polimeriziral vinil klorid. Toda nastali PVC je bil tog in krhek, kar je omejevalo njene aplikacije.

Preoblikovanje druge svetovne vojne in PVC: Druga svetovna vojna je zaznamovala prelomnico za PVC. Povpraševanje po materialih med vojno je privedlo do raziskav o izboljšanju lastnosti PVC. V štiridesetih letih prejšnjega stoletja je napredek v tehnikah polimerizacije in dodajanja mehčalcev pretvoril PVC v prožen in vsestranski material.

Povojni razcvet: Po vojni je PVC doživel hitro rast. Njegova trajnost, kemična odpornost in cenovno dostopnost so bili idealni za široko paleto aplikacij. Zlasti PVC cevi so revolucionirali vodovod in gradnjo.

Neprekinjene inovacije: PVC se od svojega povojnega razcveta še naprej razvija. Danes je na voljo v različnih oblikah, od toge do prilagodljivih, njegove formulacije pa se nenehno izpopolnjujejo za večjo uspešnost in trajnost.

Potovanje PVC iz preproste spojine do globalnega blaga je dokaz človeške iznajdljivosti in naša sposobnost oblikovanja materialov, ki posledično oblikujejo naš svet.

Kemija PVC

Da bi resnično razumeli PVC, se potopimo v svet kemije. PVC -jeve edinstvene lastnosti in vsestranskost sta posledica njegove molekularne strukture in kemičnih procesov, ki jo ustvarjajo.

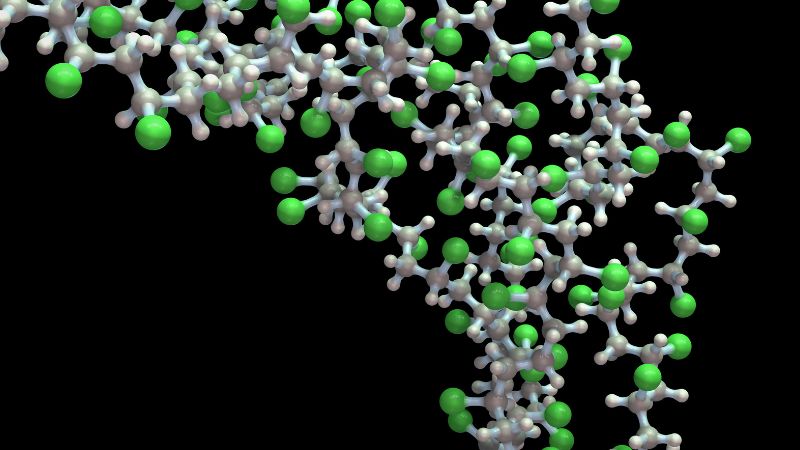

Kemična sestava: V svojem jedru je PVC polimer, ki je velika molekula, sestavljena iz ponavljanja manjših enot, imenovanih monomeri. Za PVC je monomer vinil klorid, preprosta spojina, sestavljena iz atomov ogljika, vodika in klora. Njegova kemična formula je C2H3Cl.

Vloga klora: Ena od ključnih značilnosti PVC je prisotnost atomov klora znotraj njegove strukture. Ti atomi klora znatno prispevajo k lastnostim PVC. Klor je elektronegativen, kar pomeni, da ima močno privlačnost za elektrone. Kot rezultat tega je prisotnost atomov klora v PVC-ju sama po sebi odporna proti ognju in manj verjetno, da podpira zgorevanje. To je ključni razlog, da se PVC pogosto uporablja v aplikacijah, kjer je skrb za požarno varnost, kot je električna izolacija ožičenja. Poleg tega atomi klora v PVC zagotavljajo kemično odpornost, zaradi česar je zelo odporen na številne kisline, baze in kemikalije.

Različne oblike PVC: PVC lahko sprejme različne oblike, odvisno od stopnje polimerizacije in dodajanja mehčalcev in drugih dodatkov. Togi PVC, znan kot PVC-U, je močan in se pogosto uporablja pri gradnji za cevi, okovje in okenske okvire. Prilagodljiv PVC, imenovan PVC-P, se uporablja za izdelke, kot so medicinske cevi in izolacija kabla.

Vrste in ocene PVC

PVC je na voljo v različnih vrstah in ocenah, od katerih je vsaka prilagojena določenim aplikacijam. Raziščite te klasifikacije in njihove edinstvene značilnosti.

1. PVC-U (neplastičen PVC):

- Lastnosti: Toga, odlična kemična odpornost, visoka mehanska trdnost, odpornost proti plamenu, primerna za zunanjo uporabo.

- Prijave: Cevi za vodo in kanalizacijo, okenski okvirji, kabelski vodniki, industrijski rezervoarji in oprema.

2. PVC-P (plastiran PVC):

- Lastnosti: Prilagodljiva, dobra električna izolacija, odporna na olja in kemikalije, odporna na plamen, primerna za hladna okolja.

- Prijave: Medicinske cevi, izolacija električnega kabla, napihljive strukture (npr. Igrače in zračne vzmetnice), fleksibilne cevi in zavese.

3. PVC-C (klorirani PVC):

- Lastnosti: Odlična visokotemperaturna odpornost, vrhunska kemična odpornost, izboljšana mehanske lastnosti v primerjavi s PVC-U, odpornimi na plamen.

- Prijave: Oprema za kemično predelavo, prezračevalni sistemi za jedko okolje, visokotemperaturne cevi in armature.

4. Foomed PVC:

- Lastnosti: Lahka, nizka gostota, dobre izolacijske lastnosti, vremenske odporne, odporne na udarce.

- Prijave: Signalizacije in oglaševalske plošče, razstavne plošče, izdelava modelov in notranja dekoracija.

5. PVDC (poliviniliden klorid):

- Lastnosti: Izjemne lastnosti pregrade za pline in vlago, odlična kemična odpornost, prozorna, dobra toplotna odpornost.

- Prijave: Embalaža s hrano (npr. Saran Wrap), prevleke za embalažo pretiha, zaščitne plasti za fleksibilne filme.

6. CPVC (klorirani polivinil klorid):

- Lastnosti: Izboljšana toplotna odpornost v primerjavi s PVC-U, dobra kemična odpornost, odporne na plamen, močne mehanske lastnosti, primerne za porazdelitev tople vode.

- Prijave: Cevi in okovje tople vode, sistemi za brizganje požara, cevovodi za kemično predelavo.

7. UPVC (neplastičen polivinil klorid):

- Lastnosti: Toga, trpežna, odlična odpornost proti vremenskim vplivom in UV sevanju, nizka vzdrževanje, dobra dimenzijska stabilnost.

- Prijave: Strelni materiali, žlebovi in iztoki, zunanje pohištvo, obloga in tiru.

Te različne vrste in ocene PVC ponujajo oblikovalcem in inženirjem prilagodljivost, da izberejo najprimernejši material za njihove posebne aplikacije, ne glede na to, ali gre za njegovo kemično odpornost, električne lastnosti, prožnost ali temperaturno odpornost.

Lastnosti PVC

Polivinil klorid (PVC) je znan po svoji edinstveni kombinaciji lastnosti, zaradi česar je vsestranski material s široko paleto aplikacij. V tem poglavju se bomo poglobili v ključne fizikalne in kemijske lastnosti, ki definirajo PVC.

1. trajnost: Ena izmed izstopajočih lastnosti PVC je njegova trajnost. Lahko prenese ostre okoljske razmere, vključno z izpostavljenostjo sončni svetlobi, vlagi in kemikalijam, brez znatne razgradnje. Zaradi tega je PVC priljubljena izbira za zunanje in dolgotrajne aplikacije.

2. upornost plamena: PVC je sam po sebi odporen proti ognju. Ima visoko temperaturo vžiga in ne podpira zgorevanja. Ko je izpostavljen plamenom, se nagiba k samoodločvanju, kar je ključna varnostna funkcija. Kot rezultat, se PVC običajno uporablja pri gradbeništvu, električnem ožičenju in prevozu, kjer je skrb za požarno varnost.

3. Kemična odpornost: PVC je zelo odporen na številne kisline, baze in kemikalije. Če je izpostavljena širokemu spektru snovi, se ne korodira ali poslabša, zaradi česar je idealna izbira za opremo za kemično predelavo, sisteme cevovodov in posode.

4. Električne izolacijske lastnosti: PVC je odličen električni izolator. Ima nizko električno prevodnost, zaradi česar je primeren za uporabo pri električnem ožičenju in izolaciji kabla. Poleg tega je njegova odpornost plamena ugodna pri električnih aplikacijah, kjer je požarna varnost najpomembnejša.

5. Mehanska trdnost: Zlasti togi PVC kaže impresivno mehansko trdnost. Lahko prenese velike obremenitve in udarce, zaradi česar je dragocen material za gradbeništvo in konstrukcijske uporabe.

6. Termična stabilnost: PVC ima dobro toplotno stabilnost in ohranja svoje lastnosti pri širokem razponu temperatur. PVC-C, klorirana oblika PVC, je še posebej znan po visokotemperaturni odpornosti in lahko obravnava povišane temperature v primerjavi s standardnim PVC.

7. odpornost na vodo: PVC je sam po sebi vodoodporen, zato se pogosto uporablja v vodovodnih in vodnih sistemih. Ko je izpostavljen vodi, ne korodira ali oslabi, zaradi česar je zanesljiva izbira za te aplikacije.

8. vsestranskost: Vsestranskost PVC je izstopajoča funkcija. S prilagoditvijo metod formulacije in obdelave se lahko pretvori v toge ali prilagodljive materiale, prilagojene tako, da ustreza določenim aplikacijam. Ta prilagodljivost je ključni razlog, da PVC najde uporabo v tako najrazličnejših panogah.

9. Reciklirano: PVC je mogoče reciklirati, prizadevanja za izboljšanje njegove trajnosti pa še potekajo. Medtem ko so v preteklosti zaskrbljeni zaradi vpliva PVC na okolje, napredek v praksah recikliranja in trajnostne proizvodnje obravnava ta vprašanja.

Edinstvene lastnosti PVC -ja omogočajo izbiro v številnih panogah, od gradbeništva in zdravstvenega varstva do avtomobilov in širše. Njegova trajnost, odpornost plamena, kemična stabilnost in prilagodljivost še naprej postavljajo PVC dragoceno sredstvo za inženirstvo in oblikovanje.

Proces proizvodnje PVC

Potovanje polivinil klorida (PVC) iz njegovih surovin do vsestranskega materiala, ki ga poznamo danes, je fascinantno. V tem poglavju bomo odkrili proizvodne procese, ki sodelujejo pri proizvodnji PVC, in kako oblikujejo njegove lastnosti.

1. polimerizacija: Potovanje PVC se začne s polimerizacijo monomerov vinil klorida. Ta postopek vključuje povezovanje molekul vinil klorida skupaj, da tvori dolge verige. V proizvodnji PVC se uporablja več metod polimerizacije:

- Suspenzijska polimerizacija: Ta metoda vključuje suspendiranje kapljic vinil klorida v vodi in nato sproži postopek polimerizacije s toploto in katalizatorjem.

- Polimerizacija emulzije: Tu se vinil klorid polimerizira v vodni emulziji, kar ustvarja material iz lateksa.

- Polimerizacija v razsutem stanju: V tej metodi se vinil klorid polimerizira v čisti, nerazredčeni obliki.

2. Proizvodnja smole: Nastali polimer, ki ga pogosto imenujemo PVC smole, je nadaljnjo obdelavo. V tej fazi se uvajajo dodatki za izboljšanje specifičnih lastnosti. Pogosti dodatki vključujejo mehčale, da bi PVC prilagodljivi, stabilizatorji, da preprečijo razgradnjo, pigmente za obarvanje in polnila za izboljšanje trdnosti in zmanjšanje stroškov.

3. Mešanje in sestavljanje: PVC smola se meša z dodatki v natančnih razmerjih z uporabo mešalnikov visoke hitrosti. Ta postopek zagotavlja, da so aditivi enakomerno razporejeni po matrici PVC.

4. Extruzija ali oblikovanje: PVC spojina se nato dovaja v ekstruder ali stroj za oblikovanje, kjer se segreva in oblikuje v želeno obliko. Ekstrukcija se uporablja za izdelke, kot so cevi, profili in pločevine, medtem ko se oblikovanje uporablja za bolj zapletene modele.

5. Hlajenje in rezanje: Po ekstrudiranju ali oblikovanju se PVC izdelki ohladijo, da nastavijo svojo obliko. Lahko jih tudi razrežemo na želeno dolžino ali obliko.

6. Nadzor kakovosti: Ukrepi za nadzor kakovosti so sestavni del proizvodnje PVC. Izdelki so podvrženi različnim testom, s katerimi se zagotovi, da izpolnjujejo industrijske standarde za lastnosti, kot so dimenzijska natančnost, natezna trdnost in kemična odpornost.

7. embalaža in distribucija: Ko izdelki PVC prenašajo nadzor kakovosti, se pakirajo in distribuirajo na predvidene trge in panoge.

Proizvodnja PVC je zelo nadzorovan postopek, ki omogoča prilagajanje PVC izdelkov za izpolnjevanje posebnih zahtev. Izbira aditivov, metode polimerizacije in pogojev obdelave igrajo vlogo pri oblikovanju končnih lastnosti PVC.

Aplikacije PVC

Polivinil klorid (PVC) se je uveljavil kot material izjemne vsestranskosti in iskal aplikacije v širokem številu industrij. Njegova edinstvena kombinacija lastnosti je v različnih okoliščinah nepogrešljiva. V tem poglavju bomo raziskali raznolike in vitalne vloge PVC v našem vsakdanjem življenju.

1. gradbena industrija:

- Cevi in okovje: PVC cevi se pogosto uporabljajo za distribucijo vode, odtok in kanalizacije. So lahki, odporni proti koroziji in imajo dolgo življenjsko dobo.

- Okrajni okviri: Izolacijske lastnosti PVC -ja omogočajo priljubljeno izbiro za okna. Pomaga izboljšati energetsko učinkovitost in zmanjšuje stroške ogrevanja in hlajenja.

- Profili in tiru: PVC profili se uporabljajo za vrata, okvirje in tiru zaradi odpornosti na vremenske vplive, poškodbe termita in propadanje.

2. Sektor zdravstvenega varstva:

- Medicinska cev: Prilagodljiv PVC se uporablja za medicinske cevi, kot so intravenske (IV) linije, katetre in sisteme za dostavo kisika zaradi njegove biokompatibilnosti in prožnosti.

- Medicinska embalaža: PVC se uporablja pri embalaži farmacevtskih izdelkov in medicinskih pripomočkov, kar zagotavlja oviro proti kontaminaciji.

3. Avtomobilske aplikacije:

- Avtomobilska notranjost: PVC se uporablja v notranjosti avtomobilov za prevleke na armaturni plošči, materiale za sedeže in talne obloge zaradi svoje trajnosti in enostavnosti vzdrževanja.

- Ožičenje in kablo: PVC se uporablja pri avtomobilski izolaciji ožičenja, kjer so njegove električne izolacijske lastnosti kritične.

4. Električna in elektronika:

- Kabelska izolacija: PVC se uporablja za izolacijo električnih kablov, s čimer zagotavlja varen prenos električne energije.

- Žični premazi: Uporablja se za žične prevleke, ščiti pred obrabo in okoljskimi dejavniki.

5. Signage in grafika:

- Vinilna oznaka: Vinilni listi na osnovi PVC se uporabljajo za oglaševalske znake, transparente in nalepke zaradi trajnosti in sposobnosti zadrževanja živih odtisov.

6. Pakiranje in potrošniške izdelke:

- Embalaža pretisni omoti: PVC se zaradi preglednosti in pregradnih lastnosti uporablja pri pretisni embalaži za farmacevtske izdelke in potrošniške izdelke.

- Pisarniški material in igrače: PVC se zaradi enostavnosti oblikovanja in prilagodljivosti uporablja za pisarniške izdelke, igrače in napihljive izdelke.

7. Kmetijstvo:

- PVC cevi in okovje se v kmetijstvu pogosto uporabljajo za namakalne sisteme in porazdelitev vode na kmetijah.

8. Razne prijave:

- Obutev: PVC se zaradi proizvodnje obutve, vključno z dežnimi škornji in sandali, uporablja zaradi svojih vodoodpornih lastnosti.

- Športna oprema: Uporablja se za predmete, kot so športne kroglice in napihljive strukture.

- Morsko in vodno plovilo: PVC se uporablja v morskih aplikacijah, kot so napihljivi čolni in boje zaradi svoje plovnosti in odpornosti na slano vodo.

Izjemna vsestranskost PVC je na polnem prikazu v številnih vlogah, ki jih igra v različnih panogah. Od povečanja varnosti in udobja naših domov do prispevanja k napredku v zdravstvu in prevozu se PVC še naprej razvija in inovira, kar zagotavlja, da ostaja bistveni material v našem sodobnem svetu.

Okoljski vidiki

Ko raziskujemo svet polivinil klorida (PVC), je bistveno upoštevati vpliv tega vsestranskega materiala na okolje. PVC se je zaradi svojih proizvodnih procesov in potencialnih okoljskih učinkov soočal z nadzorom in razpravljal. V tem poglavju bomo preučili tako pomisleke kot prizadevanja za trajnost znotraj PVC industrije.

1. proizvodnja in emisije plina s klorom:

Eden glavnih okoljskih pomislekov, povezanih s proizvodnjo PVC, je sproščanje klora. Med proizvodnim postopkom, zlasti v zgodnjih fazah proizvodnje PVC, se kot stranski proizvod proizvaja plin klor. Klor je zelo reaktiven in potencialno nevaren plin, njegove emisije pa so vzbudile okoljske težave. Pomembno pa je opozoriti, da je bil v proizvodni tehnologiji PVC dosežen pomemben napredek. Sodobni objekti so izvedli ukrepe za zajem in nevtralizacijo emisij klora, kar zmanjšuje njihov vpliv na okolje.

2. PVC recikliranje:

PVC je mogoče reciklirati, vendar predstavlja nekaj izzivov v primerjavi z drugimi plastiko. En izziv je prisotnost različnih dodatkov v PVC izdelkih, ki lahko zapletejo postopek recikliranja. Za reševanje tega so se programi recikliranja za PVC z leti izboljšali, zaradi česar so vse bolj sposobni in okolju prijazni.

3. Analiza življenjskega cikla:

Okoljski vpliv PVC je zelo odvisen od življenjskega cikla. Dejavniki, kot so proizvodnja, prevoz, uporaba in odlaganje, prispevajo k celotnemu okoljskemu odtisu PVC izdelkov. Analiza življenjskega cikla je dragoceno orodje za oceno teh vplivov in prepoznavanje področij za izboljšanje.

4. ftalati in zdravstvene skrbi:

Ftalati so skupina kemikalij, ki se včasih uporabljajo kot mehčale v PVC formulacijah. Obstajajo zaskrbljenost zaradi potencialnega izpita ftalatov iz PVC izdelkov, zlasti v igračah in medicinskih pripomočkih. Za reševanje teh pomislekov obstaja trend razvoja PVC formulacij brez ftalata.

5. Dioksini in sežiganje:

Proizvodnja in sežiganje PVC lahko povzroči sproščanje dioksinov, zelo strupenih spojin. Strogi predpisi in izboljšani proizvodni procesi so znatno zmanjšali emisije dioksina. Pravilna prizadevanja za ravnanje z odpadki in recikliranje so bistvenega pomena za zmanjšanje okoljskega vpliva sežnega PVC -ja.

Polivinil klorid (PVC) je vsestranski material s kompleksnim naborom okoljskih vidikov. Medtem ko obstajajo izzivi, je PVC industrija močno napredovala pri reševanju okoljskih pomislekov. Inovacije v proizvodni tehnologiji, praksah recikliranja in razvoju trajnostnih PVC formulacij prispevajo k zmanjšanju vpliva na okolje PVC.

Prednosti in morebitne pomanjkljivosti PVC

Polivinil klorid (PVC) je material z bogato zgodovino in impresivno paleto aplikacij. V tem poglavju bomo preučili tako prednosti, ki so poganjale PVC do pomembnosti, kot tudi morebitne pomanjkljivosti, ki so sprožile razprave in privedle do nenehnih izboljšav.

Prednosti PVC

- Vsestranskost: PVC je neverjetno vsestranski, njegove lastnosti pa so lahko prilagojene tako, da ustrezajo različnim aplikacijam. Od togega PVC -ja, ki se uporablja v gradbeništvu do prilagodljivega PVC v medicinskih napravah, ga je mogoče prilagoditi tako, da ustreza posebnim potrebam.

- Trajnost: PVC je znan po svoji trajnosti in dolgem življenjskem obdobju. Zdrži ostre okoljske razmere, zaradi česar je idealen za aplikacije na prostem.

- Odpornost plamena: PVC-jeva lastna upornost plamena in lastnosti samoodločbe so varna izbira v aplikacijah, kjer je skrb za požarno varnost.

- Kemična odpornost: PVC je zelo odporen na številne kisline, baze in kemikalije, kar zagotavlja njegovo dolgo življenjsko dobo v korozivnem okolju.

- Električna izolacija: Je odličen električni izolator, zaradi česar je primeren za ožičenje in izolacijo kabla.

- Stroškovno učinkovit: PVC je pogosto stroškovno učinkovit v primerjavi z alternativnimi materiali, kar prispeva k njegovi široki uporabi v različnih panogah.

Potencialne pomanjkljivosti PVC

- Proizvodnja klora: Proizvodnja PVC vključuje uporabo klora plina, ki je vzbudil okoljske pomisleke. Medtem ko so se emisije z izboljšano tehnologijo znatno zmanjšale, to ostaja razprava.

- Vpliv okolja: Vpliv na okolje PVC je odvisen od različnih dejavnikov, vključno z njegovim življenjskim ciklom. Skrbi vključujejo odstranjevanje PVC izdelkov in potencial za strupene emisije, če so sežgani.

- Zdravstvene težave: Nekatere študije so sprožile zdravstvene težave, povezane s PVC, zlasti glede sproščanja ftalatov in dioksinov med proizvodnjo ali odstranjevanjem. Ti pomisleki so privedli do prizadevanj za razvoj ftalata in okolju prijaznejših formulacij.

- Izzivi recikliranja: Medtem ko je PVC recikliran, predstavlja izzive pri recikliranju zaradi prisotnosti različnih dodatkov. Ločevanje PVC od drugih plastike je lahko zapleteno, vendar se programi recikliranja nenehno izboljšujejo.

- Togost in krhkast: Togi PVC je lahko krhek pri nizkih temperaturah, kar lahko omeji njegovo uporabo v ekstremnih hladnih razmerah.

Uporaba PVC vključuje kompromis med njegovimi prednosti in morebitnimi pomanjkljivostmi. Strokovnjaki v industriji, oblikovalci politike in potrošniki morajo pri izbiri PVC za posebne aplikacije upoštevati te dejavnike. Napredek na področju tehnologije, recikliranja in trajnostnih pobud v industriji PVC je namen reševanja okoljskih in zdravstvenih pomislekov, kar še izboljšuje njeno vrednost.

Varnostni in zdravstveni premisleki

Varnostni in zdravstveni vidiki polivinil klorida (PVC) so ključni vidiki, zlasti glede na njegovo široko uporabo v različnih panogah. V tem poglavju se bomo poglobili v varnostne ukrepe, predpise in morebitne zdravstvene težave, povezane s PVC.

Varnostni ukrepi pri ravnanju s PVC

- Dihalna zaščita: Pri delu s PVC v proizvodnih ali predelovalnih okoljih bodo morda morali delavci uporabiti dihalno zaščito, kot so maske ali respiratorji, da se izognejo vdihavanju delcev ali hlapov v zraku.

- Zaščita kože: Priporočamo zaščitna oblačila, rokavice in varnostna očala ali očala, da se čim bolj zmanjšajo stik s kožo in izpostavljenost očesnemu materialu, zlasti med postopki rezanja, brušenja ali varjenja.

- Prezračevanje: Ustrezni prezračevalni sistemi so ključni za nadzor in odstranjevanje morebitnih emisij ali hlapov, ustvarjenih med proizvodnim procesom PVC.

- Ravnanje in shranjevanje: PVC materiale je treba obravnavati in shraniti v skladu s priporočili proizvajalca, da zmanjšate tveganje za telesne poškodbe in zagotovite varne pogoje skladiščenja.

Predpisi in standardi

- Uprava za varnost in zdravje pri delu (OSHA): OSHA v Združenih državah Amerike določa varnostne predpise na delovnem mestu, ki lahko veljajo za ravnanje in uporabo PVC. Delodajalci so odgovorni za zagotavljanje skladnosti s temi predpisi za zaščito svojih zaposlenih.

- Okoljski predpisi: Okoljske agencije v različnih državah urejajo emisije in odstranjevanje materialov, povezanih s PVC, zlasti v zvezi s sproščanjem klora in potencialnih vplivov na okolje.

Zdravstvene težave

- Izpostavljenost s klorom: Eden od primarnih zdravstvenih pomislekov, povezanih s PVC, je potencialno sproščanje klora plina med proizvodnjo ali v primeru požara. Izpostavljenost plina klora lahko povzroči draženje dihal in oči, v visokih koncentracijah pa je lahko strupena.

- Ftalati: Ftalati so skupina kemikalij, ki se včasih uporabljajo kot mehčale v PVC formulacijah. Obstajajo zdravstveni pomisleki glede sproščanja ftalatov iz PVC izdelkov, zlasti v igračah in medicinskih pripomočkih. Kot rezultat, obstaja trend razvoja PVC formulacij brez ftalata.

- Dioksini: Proizvodnja in sežiganje PVC lahko povzroči sprostitev dioksinov, ki so zelo strupene spojine. Strogi predpisi in izboljšani proizvodni procesi so zmanjšali emisije dioksina, vendar spremljanje in nadzor nenehno skrbijo.

PVC v zdravstvu

V zdravstvu se PVC pogosto uporablja za medicinske pripomočke in embalažo. Varnost PVC v medicinskih aplikacijah je predmet nadzora. Prizadeva si, da bi zagotovili, da PVC medicinski izdelki izpolnjujejo regulativne standarde in zmanjšajo morebitna zdravstvena tveganja za bolnike.

Varnostni in zdravstveni premisleki so najpomembnejši pri uporabi PVC, zlasti v panogah, kjer lahko delavci ali potrošniki pridejo v stik z materiali PVC. Strogo spoštovanje varnostnih ukrepov, skladnost s predpisi in stalne raziskave morebitnih zdravstvenih pomislekov so bistvene za zagotovitev varne uporabe PVC v različnih aplikacijah.

Prihodnost PVC – Inovacije in trajnost

Polivinil klorid (PVC) je že od svojega odkritja daleč, saj se razvija v vsestranski material z raznolikimi aplikacijami. Ko gledamo v prihodnost, je več ključnih trendov in razvoja pripravljenih oblikovati vlogo PVC v našem svetu.

1. trajnostne prakse in krožno gospodarstvo

PVC industrija aktivno prizadeva za izboljšanje trajnosti in zmanjšanje vplivov na okolje. Tukaj je, kako:

- Pobude za recikliranje: Programi recikliranja za PVC se še naprej širijo. Recikliranje PVC materialov ne ohranja samo virov, ampak tudi pomaga zmanjšati odpadke na odlagališčih.

- Formulacije brez ftalata: Vse več je premik k razvoju in uporabi PVC-formulacij brez ftalata, reševanja skrbi za zdravje in usklajevanje s potrošniškimi preferencami do varnejših izdelkov.

- Biorazgradljivi dodatki: V teku so raziskave za vključitev biološko razgradljivih dodatkov v PVC formulacije, ki omogočajo, da se PVC izdelki na koncu življenjskega cikla lažje pokvarijo.

- Zelena kemija: Razvoj okolju prijaznejših proizvodnih procesov in dodatkov PVC je v središču tekočih raziskav.

2. tehnološke inovacije

Napredek v tehnologiji PVC odpira nove možnosti:

- Pametni PVC materiali: Inovacije v PVC aditivih in kompozitih omogočajo razvoj “pametno” Materiali z izboljšanimi lastnostmi, kot so samozdravljenje in izboljšana električna prevodnost.

- Nanotehnologija: Vključitev nanomaterialov v PVC formulacije povečuje lastnosti zmogljivosti, zaradi česar je PVC še bolj prilagodljiv in učinkovit.

3. Regulativna skladnost

Ker skrbi glede vplivov na okolje in zdravje še vedno obstajajo, se pričakuje, da bodo regulativni standardi in certifikati v industriji postali strožji. Proizvajalci PVC bodo verjetno vlagali v izpolnjevanje teh standardov, da bi zagotovili varnost in trajnost svojih izdelkov.

4. Globalna širitev

Vsestranskost in stroškovno učinkovitost PVC-ja sta dragoceno gradivo v gospodarstvih v nastajanju. Ker se razvoj in infrastrukture in urbanizacija še naprej povečujeta po vsem svetu, naj bi se svetovno povpraševanje po PVC povečalo, zlasti pri gradbeništvu in zdravstvenih aplikacijah.

5. Trajnostne gradbene prakse

V gradbeništvu se vedno bolj osredotoča na prakse trajnostnih gradnje. PVC izdelki, kot so energetsko učinkovita okna in PVC strešne membrane, prispevajo k ohranjanju energije in trajnosti, ki se uskladijo z gibanjem zelene stavbe.

Polivinil klorid (PVC) ima obetavno prihodnost, ki jo poganjajo stalna prizadevanja za izboljšanje trajnosti, varnosti in uspešnosti. PVC industrija se zavezuje k reševanju okoljskih pomislekov, zmanjšanju ogljičnega odtisa in sprejemanju tehnoloških inovacij.

Ker se PVC še naprej prilagaja spreminjajočim se zahtevam in predpisom, bo verjetno ostal pomemben material v širokem obsegu panog. Njegova vsestranskost, trajnost in stroškovno učinkovitost zagotavljajo, da bo PVC igral pomembno vlogo pri oblikovanju našega sveta, tako zdaj kot v prihodnosti.

Zaključek: PVC – Vsestranski material, ki oblikuje naš svet

Polivinil klorid (PVC) v veliki tapiseriji materialov, ki tkajo naš sodobni svet, stoji kot izjemna nit. PVC se je iz svojega skromnega izvora kot eksperimenta s klorovim plinom in vinilnim kloridom razvil v vsestranski, trpežen in prilagodljiv material, ki se dotakne skoraj vseh vidikov našega življenja.

Ko smo se odpravili skozi poglavja tega celovitega vodnika, smo bili priča potovanju PVC od njene ustanovitve do njegove ključne vloge v gradbeništvu, zdravstvu, avtomobilskih in neštetih drugih panogah. Raziskali smo njegovo edinstveno kemijo, široko paleto vrst in ocen ter izjemne lastnosti, zaradi katerih je nepogrešljiva. Razpravljali smo o njegovih okoljskih vidikih, prednostih, morebitnih pomanjkljivostih in stalnih prizadevanjih, da bi bila bolj trajnostna in varna.

PVC je več kot le material, priča o človeški iznajdljivosti in inovacijah. Odseva našo sposobnost izkoriščanja elementov in inženirskih rešitev, ki izboljšujejo našo kakovost življenja. PVC ni samo oblikoval našega sveta, ampak še naprej to počne, zahvaljujoč nenehnim raziskovanjem, razvojem in zavezanosti panog in posameznikov, da ga lahko uporabijo odgovorno.

Ko gledamo na prihodnost, se bo PVC še naprej razvijal in sprejel trajnost, inovacije in skladnost s strogimi predpisi. Še naprej se bo prilagajala potrebam spreminjajočega se sveta, ki bo prispevala k naši varnosti, udobju in napredku.

Ne glede na to, ali gre za PVC cevi, ki nosijo čisto vodo do naših domov, fleksibilno PVC cev, ki varčujejo v medicinskih okoljih, ali trajne PVC okenske okvire, ki izboljšujejo energetsko učinkovitost, PVC ostaja sestavni del tkanine naše sodobne družbe.

Ko smo se poslovili od tega raziskovanja PVC -ja, vas vabimo, da ostanete radovedni, da nadaljujete z inovacijami in cenite nešteto načinov, kako materiali, kot je PVC, oblikujejo svet okoli nas. Potovanje odkritja se nikoli ne konča in zgodba o PVC -ju še zdaleč ni končana.