pengenalan

Definisi pencetakan suntikan besar

Pencetakan suntikan besar merujuk kepada proses fabrikasi untuk menghasilkan komponen plastik yang besar, biasanya mereka yang melebihi 24 inci dalam satu dimensi. Ia melibatkan suntikan plastik cair ke dalam rongga acuan yang cukup besar dan merupakan kaedah yang sangat diperlukan untuk membuat bahagian -bahagian besar yang digunakan dalam pelbagai sektor.

Sejarah dan evolusi ringkas

Bermula dengan perkembangan mesin pencetakan suntikan pertama pada tahun 1870 -an, teknologi telah berkembang dengan ketara. Pada pertengahan abad ke-20, permintaan untuk barangan plastik yang lebih besar untuk kegunaan perindustrian mendorong pertumbuhan suntikan besar. Kemajuan dalam reka bentuk bantuan komputer (CAD), pembuatan bantuan komputer (CAM), dan pengenalan mesin pencetakan suntikan tinggi telah merevolusikan bidang ini.

Kepentingan dalam pembuatan moden

Pencetakan suntikan besar adalah penting dalam industri yang memerlukan kekuatan tinggi, ringan, dan kompleks. Proses ini menawarkan skalabilitas, kebolehulangan, dan kecekapan bahan yang tidak dapat ditandingi, menjadikannya sangat diperlukan dalam pembuatan moden.

Bahagian 1: Fundamental pengacuan suntikan besar

Proses pencetakan suntikan

Proses ini bermula dengan memberi makan granul plastik ke dalam laras yang dipanaskan, di mana mereka cair. Skru salingan atau penyuntik ram kemudian memaksa plastik cair ke dalam rongga acuan. Sebaik sahaja disejukkan, bahagian itu dikeluarkan, dan kitaran bermula lagi. Kaedah ini cemerlang dalam menghasilkan bahagian yang sama dalam jumlah yang tinggi dengan sisa minimum.

Standard vs skala besar

Tidak seperti Pencetakan suntikan standard, mesin pencetakan suntikan besar beroperasi dengan daya pengapit yang lebih tinggi -selalunya melebihi 1000 tan. Mereka boleh menampung saiz acuan yang lebih besar dan mempunyai keupayaan untuk menyuntik bahan plastik dengan saiz pukulan sehingga beratus -ratus pound berat.

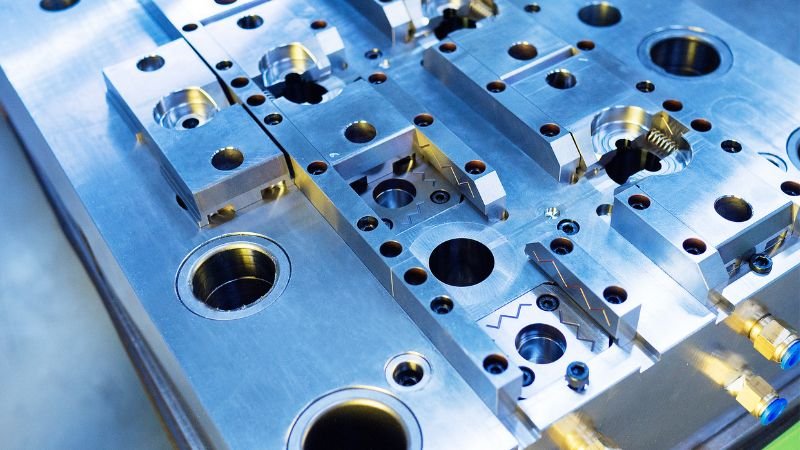

Gambaran keseluruhan peralatan

Mesin pengacuan suntikan besar dilengkapi dengan ciri-ciri canggih seperti sistem kawalan ketepatan tinggi, pelbagai unit suntikan untuk suntikan bersama, dan sistem penyejukan yang dipertingkatkan untuk penyejukan bahagian seragam. Mesin -mesin khusus ini penting untuk pengeluaran bahagian besar yang berjaya.

Bahagian 2: Bahan dan Reka Bentuk untuk Pencetakan Suntikan Besar

Jenis bahan

Polycarbonate, poliamida, dan polistirena berimpak tinggi adalah antara banyak bahan yang sesuai untuk pengeluaran sebahagian besar. Bahan -bahan ini dipilih untuk kekuatan, rintangan terma, dan kualiti selesai.

Sifat Bahan

Ciri -ciri bahan utama seperti pengembangan haba, ketahanan terhadap rayapan, dan kekuatan tegangan sangat kritikal dalam pembuatan sebahagian besar untuk memastikan kestabilan dan prestasi sebahagian sepanjang kitaran hayatnya.

Pertimbangan reka bentuk

Reka bentuk untuk pembuatan dalam pengacuan suntikan besar mesti menangani cabaran pengecutan, warpage, dan kepekatan tekanan. Pereka sering menggunakan perisian analisis aliran untuk meramalkan dan mengurangkan isu -isu ini.

Bahagian 3: Jentera pencetakan suntikan besar

Spesifikasi mesin

Mesin nada tinggi yang digunakan dalam pengacuan suntikan besar mempunyai ciri-ciri khusus seperti silinder dwi-kereta untuk pengedaran daya seragam dan peningkatan saiz platen untuk menampung acuan yang cukup besar.

Daya pengapit

Daya pengapit untuk acuan besar boleh berkisar antara 1000 hingga 6000 tan atau lebih, yang penting untuk mengatasi tekanan suntikan yang diperlukan untuk mengisi dan mengemas rongga acuan dengan betul.

Ciri -ciri khas

Mesin tanpa bar-bar menawarkan fleksibiliti yang lebih besar dalam saiz acuan dan kemudahan perubahan acuan. Rotary Platens juga digunakan untuk aplikasi pelbagai komponen, yang membolehkan integrasi pelbagai bahan menjadi sebahagian besar.

Bahagian 4: Parameter Proses dan Pengoptimuman

Menetapkan parameter

Parameter proses dalam pengacuan suntikan yang besar, seperti suhu cair, halaju suntikan, tekanan belakang, dan masa penyejukan, adalah kritikal dalam menentukan kualiti bahagian akhir dan mesti dioptimumkan dengan teliti untuk setiap produk.

Cabaran dalam skala

Memastikan aliran cair yang konsisten dan mengekalkan integriti struktur menjadi semakin kompleks apabila peningkatan saiz bahagian. Kemajuan dalam teknologi simulasi proses membantu menangani cabaran ini sebelum pengeluaran sebenar.

Jaminan kualiti

Dalam pengacuan suntikan yang besar, kaedah ujian yang tidak merosakkan, seperti ultrasonik dan x-ray, sering digunakan pasca pengeluaran untuk menilai struktur dalaman bahagian-bahagian dan memastikan mereka memenuhi piawaian kualiti yang ketat.

Bahagian 5: Aplikasi pengacuan suntikan besar

Penggunaan industri

Industri automotif menggunakan pengacuan suntikan besar untuk menghasilkan bahagian seperti bumper, papan pemuka, dan panel pintu. Dalam aeroangkasa, ia digunakan untuk komponen kabin dan unsur -unsur struktur. Industri perkakas bergantung kepada teknologi ini untuk panel dan komponen struktur peti sejuk dan mesin basuh.

Kajian kes

Contohnya termasuk penggunaan pengacuan suntikan besar dalam sektor automotif untuk mengurangkan berat kenderaan dengan mengintegrasikan komposit kekuatan tinggi, yang mengakibatkan kecekapan bahan api yang lebih baik dan pengurangan pelepasan.

Bahagian 6: Kelebihan dan Batasan

Kelebihan ekonomi

Keupayaan untuk menghasilkan bahagian besar dalam jumlah yang tinggi dengan kualiti yang konsisten diterjemahkan ke dalam manfaat ekonomi yang besar, termasuk kos buruh yang dikurangkan dan peningkatan produktiviti.

Pertimbangan Alam Sekitar

Usaha kemampanan dalam suntikan besar memberi tumpuan kepada mengurangkan penggunaan sisa dan tenaga. Penggunaan strategi bioplastik dan kitar semula semakin meningkat untuk mengurangkan kesan alam sekitar.

Batasan

Walaupun manfaatnya, pencetakan suntikan besar memberikan cabaran seperti kos pelaburan awal yang tinggi, keperluan untuk ruang pembuatan yang besar, dan keperluan untuk pengangkutan khusus untuk bahagian yang besar.

Bahagian 7: Inovasi dan Teknologi

Kemajuan teknologi mesin

Inovasi baru -baru ini termasuk mesin pencetakan suntikan elektrik, yang menawarkan kecekapan tenaga dan ketepatan yang lebih besar berbanding dengan rakan -rakan hidraulik.

Automasi dan Robotik

Automasi, melalui penggunaan robotik, telah membenarkan ketepatan yang lebih besar dalam pengendalian dan pemangkasan bahagian -bahagian yang besar, mengakibatkan peningkatan kecekapan dan keselamatan.

Perisian dan simulasi

Kemajuan dalam perisian analisis aliran acuan membolehkan ramalan dan pengurangan isu-isu yang berpotensi semasa fasa reka bentuk, dengan ketara mengurangkan masa dan kos yang berkaitan dengan percubaan dan kesilapan.

Bahagian 8: Amalan Terbaik dan Kajian Kes

Amalan terbaik kecekapan

Mengguna pakai pendekatan pembuatan kurus, jadual penyelenggaraan yang kerap, dan menggabungkan teknologi penjimatan tenaga adalah kunci kepada operasi pengacuan suntikan yang besar.

Pemimpin industri

Syarikat -syarikat seperti Husky Suntikan Sistem Pencetakan dan Engel telah menetapkan penanda aras industri dalam pengeluaran sebahagian besar, secara konsisten berinovasi di lapangan.

Kesimpulan

Prospek masa depan

Penyepaduan bahan -bahan baru dan kemajuan teknologi yang berterusan meramalkan masa depan yang mantap untuk pengacuan suntikan yang besar, dengan potensi pertumbuhan dalam pelbagai industri.

Pertimbangan pengawalseliaan

Gambaran keseluruhan peraturan global yang mempengaruhi acuan suntikan besar, seperti pematuhan jangkauan di Eropah dan garis panduan EPA di Amerika Syarikat, akan dimasukkan.