Mi az a műanyag fröccsöntés?

A műanyag fröccsöntés olyan, mint egy varázslatos trükk mindenféle műanyag dolgok készítéséhez. A műanyag olvadásával működik, egy penészbe helyezi, majd lehűti, hogy mindent elkészítsen a játékoktól a gépi alkatrészekig.

Milyen gyakori műanyag fröccsöntési problémák vannak?

A műanyag fröccsöntés különféle problémákkal szembesülhet, amelyek befolyásolják a termék minőségét, esztétikáját és hatékonyságát. Ezek a problémák a felszíni hibáktól, például az égési jelektől és a csíkoktól kezdve a szerkezeti kérdésekig, például a vonzerejéig és a törékenységig terjednek.

Miért fontos a műanyag fröccsöntési problémák elkerülése?

Időnként a varázslat nem működik tökéletesen. A műanyag rosszul fordulhat elő, problémákat okozva. Ezek a problémák miatt a dolgok rosszul néznek ki, rosszul működnek, sőt még többet is fizethetnek a javítás. Ezért döntő fontosságú tudni, hogyan lehet megakadályozni ezeket a problémákat.

Anyagkezelés és szennyeződés

Gondoljon arra, hogy olyan műanyag cuccokat készítsen, mint például a sütemény sütése. Ha rossz tojást vagy lisztet használ, a sütemény nem lesz jól. A műanyag formázásban az anyagnak, amellyel kezdjük, tiszta és tökéletesnek kell lennie. Ha nem, akkor rossz műanyag alkatrészeket kapunk.

Anyagi tisztaság

A műanyag gyanta tisztaságának biztosítása kiemelkedő fontosságú. Még az idegen anyagok, például a por, a nedvesség vagy a szennyező anyagok perces nyomai olyan hibákhoz vezethetnek, mint az üregek, csíkok vagy akár a késztermék szerkezeti gyengeségei.

Anyagkezelés a bevált gyakorlatok

A megfelelő anyagkezelés a hibamegelőzés alapja. A gyártóknak meg kell határozniuk és be kell tartaniuk a szigorú eljárásokat az anyagok tárolására, szállítására és betöltésére. Íme néhány kulcsfontosságú bevált gyakorlat:

- Tárolási feltételek: A nyers műanyag anyagot ellenőrzött környezetben kell tárolni, hőmérsékleti és páratartalom körülményekkel, amelyek összhangban állnak az anyag specifikációival. Ez megakadályozza a nedvesség felszívódását és az anyag lebomlását.

- Anyagvizsgálat: Rendszeresen ellenőrizze a bejövő anyagszállítmányokat a sérülések vagy a szennyeződés jeleire. Elutasítson minden olyan anyagot, amely nem felel meg a minőségi előírásoknak.

- Szárítás és előkondicionálás: Sok műanyag gyanta higroszkópos, vagyis felszívja a nedvességet a levegőből. A szárítás és az előkondicionálás alapvető lépések a feldolgozás előtt az abszorbeált nedvesség eltávolításához.

- Tiszta kezelés: Az operátoroknak kesztyűt kell viselniük, és az anyag kezelése során tiszta szerszámokat kell használniuk. A csupasz kezekkel való érintkezés elkerülése segít megelőzni a szennyeződést.

- Tiszta berendezés: Győződjön meg arról, hogy az anyag bevezetése előtt minden berendezés, beleértve a garat és szállítószalagokat, tiszta és törmeléktől mentes.

- Porvezérlés: Végezze el a porszabályozási intézkedéseket a gyártási környezetben, hogy minimalizálja az anyagon levő levegőben lévő szennyező anyagok kockázatát.

Megelőzés és észlelés

Alapvető fontosságú az anyagszennyezés észlelése, mielőtt belépne a fröccsöntő gépbe. A modern technológia, mint például az inline ellenőrző rendszerek és a fejlett érzékelők, segíthetnek azonosítani az anyagminőség következetlenségeit valós időben, lehetővé téve a gyors korrekciós intézkedéseket. Kattintson, hogy megtanulja, hogyan kell kiválasztani a műanyag anyagot.

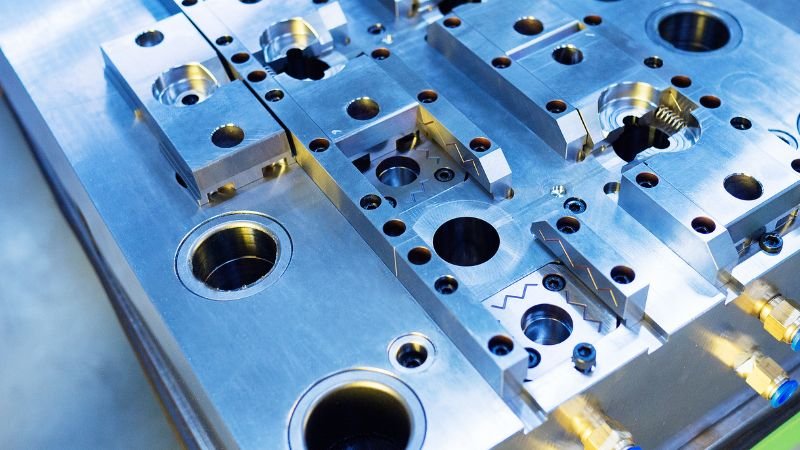

Penész kialakítása és szellőztetése

A sikeres műanyag fröccsöntési folyamat szíve magában a penészben rejlik. A jól megtervezett penész nemcsak a végtermék formáját diktálja, hanem döntő szerepet játszik a hibák megelőzésében. A penész kialakítása különféle elemeket foglal magában, az üregszerkezettől és a kapu elhelyezésétől a szellőztető oldatokig, amelyek mindegyike közvetlenül befolyásolja a kész alkatrészek minőségét.

Légcsapdák

A légcsapdák vagy a csapdába esett légzsákok a penészüregben olyan gyakori kérdés, amely nemkívánatos hibákat eredményezhet, például üregeket, égési sérüléseket és rossz felületi felületet. Ezek a bosszantó légcsapdák akkor fordulnak elő, amikor a levegő csapdába esik az injekciós folyamat során, megakadályozva, hogy az olvadt műanyag az üreg teljesen kitöltse.

A penészszellőzés szerepe

A hatékony penészszellőztetés a légcsapdák megelőzésének kulcsa. A szellőztetés magában foglalja a csapdába esett levegő útjának biztosítását a penész üregéből való elmeneküléshez, amikor az olvadt műanyag injektálódik. A megfelelő szellőzés lehetővé teszi a penész egyenletes kitöltését, és biztosítja, hogy a levegő ne kerüljön befoglalni, ami hibákhoz vezet.

- Szellőzőtervezés: A mérnökök gondosan tervezik a szellőzőnyílásokat a penészbe, hogy megkönnyítsék a levegő felszabadulását anélkül, hogy veszélyeztetnék a végtermék integritását. Ezek a szellőzőnyílások általában keskenyek és stratégiailag elhelyezkednek olyan területeken, ahol a levegő valószínűleg csapdába esik.

- Szellőztető anyag: A szellőztető anyagot gondosan ki kell választani, hogy ellenálljon a műanyag gyanta csiszoló jellegének, és hogy ellenálljon a kopásnak az idő múlásával.

- Karbantartás: A rendszeres penészkarbantartás elengedhetetlen a szellőzőnyílások tisztán és az akadályoktól mentes állapotban. Az idő múlásával a szennyeződések vagy a műanyag maradványok felhalmozódhatnak a szellőzőnyílásokban, akadályozva azok hatékonyságát.

Penészerrózió

A penészkorrózió egy másik kihívás, amely befolyásolhatja az injekciós termékek minőségét. A korrózió akkor fordul elő, amikor a penész anyag különböző tényezők miatt romlik, ideértve néhány műanyag gyanták, a nedvesség és a hőmérsékleti ingadozások agresszív jellegét.

Stratégiák a penészerrózió megelőzésére

A penész korróziójának megelőzése proaktív megközelítést igényel:

- Forma anyagválasztás: Válassza ki a korrózióálló és a feldolgozott műanyag gyanta korrózió-rezisztens anyagát. A rozsdamentes acél és a korrózióálló bevonatok életképes lehetőségek.

- Szellőzőnyílás karbantartása: Rendszeresen ellenőrizze és tartsa be a szellőzőnyílásokat a korrózió megelőzése érdekében. A védő bevonatok tisztítása és felhordása meghosszabbíthatja a szellőzőnyílások élettartamát.

- Környezetvédelmi irányítás: Fenntartja a gyártási környezetet a meghatározott hőmérsékleti és páratartalomon belül, hogy csökkentse a penészkorrózió valószínűségét. Alapvető fontosságú mind a penész hosszú élettartama, mind a végtermék minősége szempontjából.

- Felszíni kezelések: A speciális bevonatok vagy felületkezelések alkalmazása elősegítheti a penész védelmét a korrózióval szemben.

- Proaktív karbantartás: Végezzen el egy proaktív penészkarbantartási programot, amely magában foglalja a rutin takarítást és ellenőrzést a korrózió problémáinak észlelése és kezelése érdekében, mielőtt azok eszkalálódnának.

Forma kapu elhelyezése

A kapu elhelyezése a penész kialakításának egy másik kritikus szempontja, amely jelentősen befolyásolhatja az injekciós alkatrészek minőségét. A kapu az a belépési pont, amelyen keresztül az olvadt műanyag belép a penészüregbe. A megfelelő kapu elhelyezése elengedhetetlen az egységes töltés, a hibák minimalizálása és a kívánt alkatrésztulajdonságok eléréséhez.

Kapu típusai és kiválasztása

Különböző típusú kapuk állnak rendelkezésre, mindegyiknek megvan a saját előnye és korlátozása. A kapu típusának megválasztása különféle tényezőktől függ, beleértve az alkatrész -tervezést, az anyagot és a termelési mennyiséget. A közönséges kapu típusok a következők:

- Közvetlen rugózás: Közvetlenül a sprue -nál helyezkedik el, ez a kapu típus egyértelmű utat biztosít az anyagáramláshoz. Gyakran használják nagy alkatrészekre.

- Tengeralattjáró -kapu: Ez a kapu típus az alkatrész felülete alatt helyezkedik el, így kevésbé látható a késztermékben.

- Szélkapu: Az alkatrész szélén helyezve, ez a kapu típus komplex geometriával rendelkező alkatrészekhez alkalmas.

- Forró futó rendszer. Ez minimalizálja az anyaghulladékot, és gyakran használják a nagy mennyiségű termelésben.

Kapu méret és geometria

A kapu mérete és geometriája szintén kritikus szerepet játszik a fröccsöntési folyamatban. A túl kicsi kapu korlátozhatja az anyagáramlást, és kitöltési problémákhoz vezethet, míg a túlméretezett kapu túlzott anyaghasználatot és kozmetikai hibákat eredményezhet.

- Kapu méretének optimalizálása: A mérnökök gondosan kiszámítják és optimalizálják a kapu méretét olyan tényezők alapján, mint az anyagtulajdonságok, az alkatrészek kialakítása és a gyártási követelmények.

- Kapu geometria: A kapu alakja befolyásolja az anyagáramot és a nyírófeszültséget. A lekerekített vagy kúpos kapuk gyakran előnyösek a stresszkoncentráció és a kozmetikai hibák minimalizálása érdekében.

Több kapu művészete

Bizonyos esetekben a több kapuk használata javíthatja a fröccsöntési folyamatot. Több kapuk stratégiailag elhelyezkednek az anyagi eloszlás elérése érdekében, csökkentik az áramlási vezetékek vagy a hegesztési vonalak kockázatát, és biztosítják a penészüreg egyenletes csomagolását.

- Kiegyensúlyozott áramlás: Több kapu lehetővé teszi a kiegyensúlyozott anyag áramlását a penészbe, csökkentve az egyenetlen töltés és a hibák kockázatát.

- Javított kozmetikai megjelenés: Több kapu minimalizálhatja a kapujelek megjelenését a készterméken, javítva kozmetikai vonzerejét.

- Fokozott szerkezeti integritás: Az egységes töltelék és csomagolás, több kapu által megkönnyítve, hozzájárul a jobb rész erősségéhez és a szerkezeti integritáshoz.

Penészhőmérsékleti szabályozás

A penészhőmérséklet -szabályozás kritikus tényező a műanyag fröccsöntésben, amely jelentősen befolyásolhatja az alkatrészek minőségét, az esztétikát és a teljesítményt. A következetes és az egységes penészhőmérséklet fenntartása a gyártási folyamat során elengedhetetlen a hibák, például a láncszem, a mosogató jelek és a dimenzió pontatlanok megelőzéséhez.

A penészhőmérséklet fontosságát

A penészhőmérséklet befolyásolja a fröccsöntési folyamat különféle aspektusait:

- Anyagáramlás: A megfelelő penészhőmérséklet biztosítja, hogy az olvadt műanyag zökkenőmentesen áramlik a penészüregbe, minimalizálva a hibákat.

- Hűtés.

- Ciklusidő: A penészhőmérséklet optimalizálása csökkentheti a ciklusidőket, növelve a termelési hatékonyságot.

Egységes penészhőmérséklet elérése

A konzisztens penészhőmérséklet fenntartása gondos ellenőrzést és megfigyelést igényel. Íme néhány stratégia az egységes penészhőmérséklet elérésére:

- Hűtőcsatornák: A jól megtervezett hűtőcsatornák a penészben segítenek egyenletesen elosztani a hűtőfolyadékot, megakadályozva a forró foltokat vagy a hideg területeket.

- Hűtőfolyadék típus és áramlási sebesség: A hűtőfolyadék megválasztása és áramlási sebessége kritikus tényezők. A kiváló hőátadási tulajdonságokkal és az optimalizált áramlási mintákkal rendelkező hűtőfolyadékok előnyösek.

- Hőmérséklet -szabályozó rendszerek: A fejlett hőmérséklet -szabályozó rendszerek végrehajtása lehetővé teszi a penészhőmérsékletek pontos szabályozását. Ez biztosítja, hogy a penész keskeny hőmérsékleti tartományon belül maradjon a termelés során.

- A penészhőmérsékleti variáció kezelése: A penész hőmérsékleti változása egyenetlen hűtéshez és következésképpen hibákhoz vezethet. A rendszeres penészkarbantartás és a beállítások elengedhetetlenek a hőmérsékleti eltérésekhez.

Ellenőrizze a PMS penész szerszámkészítési szolgáltatást

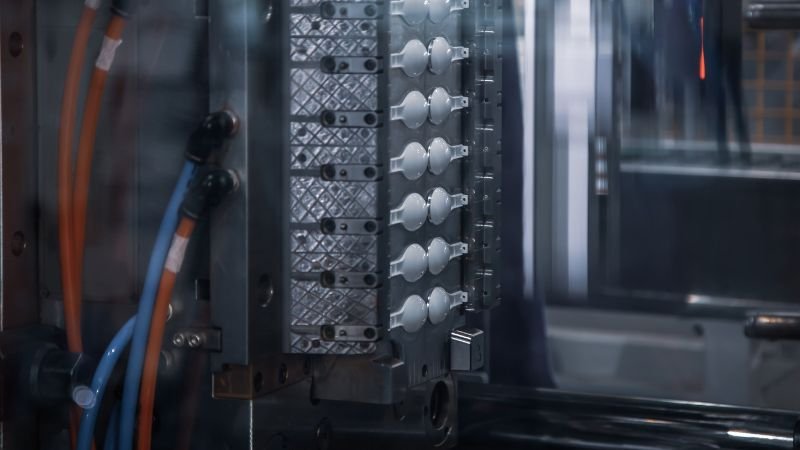

Ahogy tovább haladunk a műanyag fröccsöntési folyamat mentén, megérkezünk az injekciós szakaszba, amely az a helyzet, ahol az olvadt műanyag anyagot bevezetik a penészüregbe.

Rövid lövések: Ha a töltések elmaradnak

Rövid felvételek akkor fordulnak elő, amikor a penészüreg nem teljesen kitölthető az injekciós szakaszban. Ez hiányos vagy alulméretezett alkatrészekhez vezet, ami jelentős kérdés lehet, különösen akkor, ha a pontosság és a következetesség kiemelkedően fontos.

A rövid felvételek okai

A rövid felvételeket különféle tényezők okozhatják, beleértve:

- Elégtelen anyag: A nem megfelelő anyagmennyiség rövid lövést eredményezhet. Ez előfordulhat az anyagszámítás hibái vagy az injekciós egység hibás működése miatt.

- Forma tervezés: A nem megfelelő penész kialakítás, beleértve a kapu méretét és elhelyezkedését, korlátozhatja a műanyag áramlását, és hiányos töltelékekhez vezethet.

- Hőmérséklet és nyomás: A pontatlan hőmérséklet vagy nyomás beállítások akadályozhatják az anyag azon képességét, hogy a penész minden területére áramoljon.

Rövid lövésekre vonatkozó gyógyszerek

A rövid felvételek kezelése számos tényező gondos vizsgálatát igényli:

- Anyagmennyiség beállítása: Győződjön meg arról, hogy a megfelelő mennyiségű anyagmennyiséget az injekciós egység beállításainak kalibrálásával és ellenőrzésével injektálják.

- Penésztervezés áttekintése: Rendszeresen vizsgálja felül és optimalizálja a penészmintákat annak biztosítása érdekében, hogy a kapu mérete és a hely megkönnyítse a teljes üreg kitöltését.

- Hőmérsékleti és nyomásszabályozás: Pontosan ellenőrizze a hőmérsékletet és a nyomás beállításait, hogy elősegítse az anyag áramlását a penész minden részébe.

Túlcsomagolás: A felesleges bukás

Míg a rövid felvételek az alkatrészeket alulteljesítik, a túlcsomagolás magában foglalja a túlzott mennyiségű anyag injektálását a penészbe. Ez olyan hibákat eredményezhet, mint a láncszem, a vaku, vagy akár maga az öntőformát is.

A túlcsomagolás okai

Túlcsomagolás következhet be:

- Túlzott befecskendezési sebesség: Az anyag túl gyorsan történő befecskendezése túlcsomagoláshoz vezethet, mivel az olvadt műanyag ellenállás a penészben.

- Nagynyomású: A megemelkedett injekciós nyomás az anyag túl szoros csomagolását okozhatja a penészen belül, ami túlcsomagoláshoz vezethet.

Befecskendezési pontosság elérése

A teljes üreg kitöltésének szükségességének kiegyensúlyozásával a túlcsomagolás elkerülésével pontos ellenőrzést és megfigyelést igényel. A gyártóknak a következőkre kell összpontosítaniuk:

- Befecskendezési sebesség: Állítsa be az injekciós sebességet annak biztosítása érdekében, hogy a penészüreg megfelelően meg legyen töltve a túlcsomagolás kockázata nélkül.

- Nyomásszabályozás: Végezze el azokat a nyomásszabályozó rendszereket, amelyek fenntartják az optimális nyomásszintet az injekciós folyamat során.

- Anyagáramlás -elemzés: Használjon szoftver- és elemzési eszközöket az anyagáramlás szimulálására a penészen belül, azonosítva a potenciális problémákat a gyártás előtt.

- Penésztervezés áttekintése: Rendszeresen vizsgálja felül a penészmintákat annak biztosítása érdekében, hogy a kapu mérete és helye megkönnyítse a teljes töltést túlcsomagolás nélkül.

Tanul PMS -fröccsöntési folyamat

Ahogy a műanyag fröccsöntés szakaszaiban haladunk, elérjük a kilökő fázist, ahol a végtermék felszabadul a penészből. Ez a látszólag egyértelmű lépés bemutatja saját egyedi kihívásait, amelyek befolyásolhatják a kész rész minőségét és megjelenését.

Kidobó tűjelek

A kidobó tűjelek olyan gyakori hiányosságok, amelyek egy egyébként hibátlan termék felületét meg tudják mutatni. Ezek a jelek akkor fordulnak elő, amikor a kidobó csapok, amelyeket a termék kiürítésére használnak, kis behúzások vagy foltok hagyása.

A kidobó csapok okai

A kidobó csap jelek különféle tényezőknek tulajdoníthatók, ideértve a következőket is:

- Kidobó tű kialakítása: A nem megfelelő kialakítás, például a túlságosan nagy vagy kis csapok használata észrevehető jeleket eredményezhet a termék felületén.

- Kidobó tű pozicionálás: A rosszul elhelyezett kidobó csapok jeleket okozhatnak a szembetűnő területeken, befolyásolva a termék esztétikáját.

- Befecskendezési sebesség: A nagy befecskendezési sebesség növelheti azt az erőt, amellyel a kidobó csapok kiszorítják az alkatrészeket a penészből, ami jelekhez vezet.

Forma kitöltési egyensúlyhiány

A penész kitöltési egyensúlyhiánya akkor fordul elő, amikor az olvadt műanyag anyag nem áramlik egyenletesen a penész üregében, és olyan részeket eredményez, amelyek vastagság és tulajdonságok következetlenségei vannak.

A penész kitöltésének okai

Számos tényező hozzájárulhat a penész kitöltéséhez, beleértve:

- Nem megfelelő kapu tervezés: A túl kicsi vagy helytelenül elhelyezett kapuk akadályozhatják a műanyag anyag egyenletes áramlását.

- Hőmérsékleti variációk: Az egyenetlen penészhőmérséklet befolyásolhatja az anyagáramlást, ami az egyensúlyhiány kitöltéséhez vezethet.

- Anyagi viszkozitás: Az anyagi viszkozitás változásai egyenetlen kitöltést eredményezhetnek.

A kidobó tűjelek és az egyensúlyhiány kitöltésének jogorvoslati lehetőségei

Ezeknek a kérdéseknek a kezelése a gondos tervezés, a pontos ellenőrzés és a karbantartási gyakorlatok kombinációját igényli:

- Kidobó PIN -kódolás áttekintése: Rendszeresen vizsgálja felül a kidobó PIN -kódot a megfelelő méret és helymeghatározás biztosítása érdekében. Vegye figyelembe a több csap használatát az erő egyenletes elosztására.

- Kapu optimalizálása: Optimalizálja a kapu kialakítását az egyenletes anyagáramláshoz. A megfelelő kapu elhelyezkedése és mérete jelentősen csökkentheti a kitöltési egyensúlyhiányt.

- Hőmérsékleti szabályozás: Fenntartja az egyenletes penészhőmérsékletet az anyagi áramlás biztosítása érdekében.

- Anyag kiválasztása: Válasszon olyan anyagokat, amelyek következetes viszkozitási tulajdonságokkal rendelkeznek az egyensúlyhiány kitöltésének kockázatának csökkentése érdekében.

Ciklusidő

A ciklusidő optimalizálása az injekció utáni megfontolások alapvető szempontja. Arra utal, hogy a fröccsöntési folyamat minden ciklusának befejezéséhez szükséges idő csökkenti az anyag injekciójától az alkatrész kidobásáig.

A ciklusidőt befolyásoló tényezők

Számos tényező befolyásolja a ciklusidőt, beleértve:

- Befecskendezési sebesség: Az injekciós sebesség beállítása befolyásolhatja a ciklusidőt. A gyorsabb injekciós sebesség csökkentheti a penész feltöltéséhez szükséges időt, de más kérdéseket is bevezethet.

- Hűtési idő: A hűtési idő jelentősen hozzájárul a ciklusidőhez. A hűtési stratégiák optimalizálása elősegítheti az általános ciklusidő csökkentését.

- Kilövési folyamat: A hatékony kidobási mechanizmusok segíthetnek minimalizálni az alkatrészek eltávolítását a penészből.

Vitorlás

A Warpage tartós kihívás a műanyag fröccsöntésben, és a folyamat különböző szakaszaiban előfordulhat. A láncszem magában foglalja az öntött rész deformációját vagy torzulását, ami eltéréseket eredményez a tervezett alaktól vagy méretektől.

A lánctalpas okai

A láncszem számos tényező okozhatja:

- Egyenetlen hűtés: A hűtési sebesség változásai differenciális zsugorodást és vonzerőt eredményezhetnek.

- Anyag kiválasztása: Az anyagválasztás jelentős szerepet játszik a Warpage -ban. Egyes anyagok hajlamosabbak a vonzerejére, mint mások.

- Alkatrész -tervezés: A rossz alkatrész kialakítása, beleértve a túlzott falvastagság -variációkat, növelheti a vonzerejének kockázatát.

Stratégiák a láncmegelőzés és az enyhítés érdekében

A WARPAGE kezelése sokrétű megközelítést igényel:

- Hűtési stratégia: Optimalizálja a hűtési stratégiákat a differenciálhűtés minimalizálása és a lánc kockázatának csökkentése érdekében.

- Anyag kiválasztása: Óvatosan válassza ki azokat az anyagokat, amelyek kevésbé hajlamosak az egyes alkalmazásokra.

- Résztervezés áttekintése: Folyamatosan vizsgálja felül az alkatrészek tervezését a Warpage potenciális forrásainak azonosítása és a tervezési fejlesztések végrehajtása érdekében.

Új kérdésekkel találkozunk, amelyek megkövetelik a figyelmünket. Ezek a kérdések magukban foglalják a ködöt, a mosogató jeleket, a hegesztési vonalakat és a csíkok megfoghatatlan problémáját.

Égési jelek: A túlmelegedés hegei

Égési jelek, más néven ismert “tanúi jelek” vagy “hólyagok,” csúnya elszíneződött területek vannak az öntött alkatrészek felületén. Gyakran jelennek meg a kapu közelében vagy az alkatrész vastagabb szakaszain, és az injekciós folyamat során lokalizált túlmelegedés eredményei.

Az égési jelek okai

Az égési jelek számos tényezőnek tulajdoníthatók:

- Túlzott befecskendezési sebesség: Az olvadt műanyag gyors befecskendezése túlzott hőt generálhat, ami égési jelekhez vezet.

- Nem megfelelő hűtés: A nem megfelelő hűtés lehetővé teszi a hő felhalmozódását a lokalizált területeken, égési jeleket okozva.

- Anyagi gyanta lebomlása: Egyes műanyag gyanták hajlamosabbak a termikus lebomlásra, és égési jelekhez vezetnek.

Delamination: A réteges dilemma

A delamináció a rétegek elválasztására utal egy öntött részen belül. Jellemzően látható vonalakként vagy elválasztásokként nyilvánul meg, veszélyeztetve mind a szerkezeti integritást, mind az esztétikát.

A delamináció okai

A delamináció a következők miatt fordulhat elő

- Nem megfelelő anyagkeverés: Az anyagok rossz keverése az öntési folyamat során delaminálást eredményezhet.

- Anyagszennyezés: Az anyagkezelés vagy feldolgozás során bevezetett szennyező anyagok a rétegek elválasztását okozhatják.

- Nem megfelelő olvadékhőmérséklet: A helytelen olvadékhőmérséklet -beállítások hozzájárulhatnak a delaminációhoz.

Jeting: A sebességdilemma

A sugárzás olyan jelenség, ahol az olvadt műanyag anyag nagysebességű áramlása befolyásolja a penész felületét, és látható csíkokat vagy vonalakat hoz létre a kész részen. Gyakran társul a nagy viszkolyási anyagok felhasználásával.

A sugárzás okai

A sugárhajtást kiválthatja:

- Nagy injekciós sebesség: A túlzott injekciós sebességek sugárzáshoz vezethetnek, mivel az anyag inkább a penész felületét befolyásolja, nem pedig az üregekbe.

- Kapu tervezés: A nem megfelelő kapu kialakítása súlyosbíthatja a jajtás problémáit.

Áramlási vonalak: a legkevesebb ellenállás útja

Áramlási vonalak, más néven ismert “hegesztési vonalak” vagy “kötött vonalak,” gyakran halvány vonalként vagy gerincként láthatók az alkatrész felületén. Ezek akkor fordulnak elő, amikor az olvadt műanyag anyag áramlása ellenállást és újra csatlakozik, és látható varrást hagyva.

Áramlási vonalak okai

Az áramlási vonalak az alábbiakból származhatnak:

- Anyaghűtés: A hűtési sebesség változásai az anyagot különböző időpontokban megszilárdíthatják, ami áramlási vonalakhoz vezethet.

- Összetett rész -geometria: A komplex geometriával vagy több ággal rendelkező alkatrészek hajlamosabbak az áramlási vonalakra.

A hibacsökkentés stratégiái

E hibák enyhítéséhez a tervezés, a folyamat optimalizálásának és az anyagválasztás kombinációját igényli:

- Kapu újratervezése: A megfelelő kapu kialakítása és elhelyezése csökkentheti az égési jelek, a delamináció és a sugárzás kockázatát.

- Optimalizált befecskendezési sebesség: Vezérlő injekciós sebességek a túlmelegedés és a sugárzás megakadályozása érdekében, miközben biztosítják a megfelelő anyagáramot.

- Anyag kiválasztása: Válasszon olyan anyagokat, amelyek kevésbé hajlamosak az égési pontokra és a delaminációra.

- Szerszámok és penész kialakítás: Végezze el a szerszámcsere és a penész tervezési fejlesztéseit az áramlási vonalak valószínűségének csökkentése érdekében.

Köd: A tökéletlenség ködje

Köd, gyakran nevezik “fenyegetés” vagy “Micsípés,” felhős vagy ködös felületként jelenik meg az öntött részen. Ez a hiba jelentősen befolyásolhatja a termék esztétikáját és egyértelműségét.

Köd okai

Köd fordulhat elő:

- Anyagszennyezés: Az anyagkezelés vagy feldolgozás során bevezetett szennyező anyagok ködhez vezethetnek.

- Túlmelegedés: A túlzott hőmérséklet az öntési folyamat során az anyag lebomlását okozhatja, és ködhez vezethet.

Süllyedő jelek: A behúzási kihívás

A mosogatójelek depresszió vagy bemélyedés az öntött rész felületén. Ezek akkor fordulnak elő, amikor az alkatrész vastagabb szakaszának felülete lehűl és lassabban megszilárdul, mint a belső területek.

A mosogatójelek okai

A mosogató jeleket a következők okozhatják:

- Nem megfelelő hűtés: Az egyenetlen hűtés, különösen az alkatrész vastagabb szakaszaiban, mosogatójelhez vezethet.

- Anyag zsugorodás: Az alkatrészen belüli differenciális zsugorodási sebesség mosogatójeleket eredményezhet.

Hegesztési vonalak: ahol az anyagok találkoznak

Hegesztési vonalak, más néven ismert “kötött vonalak,” akkor fordul elő, amikor két vagy több olvadt műanyag áramlási front találkozik és újra csatlakozik az injekciós folyamat során. Ezek a vonalak gyakran láthatók a kész rész felületén, és befolyásolhatják annak szerkezeti integritását.

A hegesztési vonalak okai

A hegesztési vonalak kialakulhatnak:

- Anyagi áramlási korlátozások: Az akadályok vagy geometria a penészen belül az anyagáramlás megoszlását és visszatérését okozhatja.

- Anyaghűtés: A hűtési sebesség változásai hegesztési vonalak kialakulásához vezethetnek.

Csíkok: A csúnya jelek

A csíkok, amint a nevük is sugallja, látható vonalak vagy csíkok egy öntött rész felületén. Ezeket különféle tényezők okozhatják, és gyakran kihívást jelentenek a diagnosztizáláshoz és a megoldáshoz.

A csíkok okai

A csíkok következményei:

- Anyagszennyezés: Az anyag szennyeződései vagy szennyeződései csíkokat okozhatnak.

- Nem megfelelő keverés: Az anyagok rossz keverése csíkképződéshez vezethet.

A hibafelbontás stratégiái

Ezeknek a kihívásoknak a megoldása megköveteli a tervezés, a folyamat optimalizálásának és az anyagkezelés kombinációját:

- Anyagi tisztaság: Győződjön meg arról, hogy a felhasznált anyag mentes -e szennyeződésektől és szennyeződésektől.

- Hűtési optimalizálás: Optimalizálja a hűtési stratégiákat a mosogató jelek és a köd kockázatának csökkentése érdekében.

- Penésztervezés áttekintése: Folyamatosan vizsgálja felül a penészterveket a hegesztési vonalak és csíkok potenciális forrásainak azonosítása érdekében.

- Anyag kiválasztása: Óvatosan válassza ki azokat az anyagokat, amelyek kevésbé hajlamosak a csíkképződésre és más hibákra.