Polyvinyl Chloride, o PVC per corta, hè un materiale sinteticu fascinante chì hè diventatu una parte indispensabile di a nostra vita di ogni ghjornu. Da i tubi chì portanu l'acqua in e nostre case à i dispositi medichi chì salvanu a vita in ospedali, è ancu i cavi elettrici chì alimentanu i nostri dispositi, u PVC ghjoca un rolu cruciale in innumerevoli applicazioni. In questa guida approfondita, esploreremu u mondu di u PVC, scoprendu e so urighjini, capiscenu a so chimica, scopre i so diversi tipi è immersi in i so numerosi usi. Discuteremu ancu di l'aspettu ambientale, di salute è di sicurità, è ancu di u futuru di stu materiale versatile.

Una breve storia di u PVC

A storia di PVC principia cù una storia captivante di scuperta è innuvazione. Facemu un rapidu viaghju in u tempu per scopre cumu hè ghjuntu stu materiale incredibile.

I primi esperimenti cù u cloruru di vinile: I radichi di PVC ponu esse tracciati à u principiu di u 19u seculu quandu i chimichi cuminciaru à sperimentà cù u gasu di cloru di vinile. In ogni casu, u prugressu era lentu, è u veru putenziale di stu compostu restava micca sfruttatu per decennii.

Emergenza in u XXu seculu: Ùn era finu à u principiu di u XXu seculu chì u PVC hà cuminciatu à piglià a forma cum'è un materiale viable. In u 1912, Fritz Klatte, un chimicu tedescu, polimerizza cù successu u cloruru di vinile per a prima volta. Ma u PVC resultanti era rigidu è fragile, limitendu e so applicazioni.

A Siconda Guerra Munniali è a Trasformazione di PVC: A seconda guerra mundiale hà marcatu un puntu di svolta per u PVC. A dumanda di materiali durante a guerra hà purtatu à a ricerca per migliurà e proprietà di PVC. In l'anni 1940, l'avanzati in e tecniche di polimerizazione è l'aghjunzione di plastificanti trasformanu u PVC in un materiale flexible è versatile.

Boom di a postguerra: Dopu à a guerra, u PVC hà avutu una crescita rapida. A so durabilità, a resistenza chimica è l'accessibilità l'hanu fatta ideale per una larga gamma di applicazioni. I tubi di PVC, in particulare, rivoluzionanu a fontaneria è a custruzzione.

Innovazione in corso: Dapoi u so boom post-guerra, u PVC hà cuntinuatu à evoluzione. Oghje, hè dispunibule in diverse forme, da rigida à flessibile, è e so formulazioni sò constantemente raffinate per un rendimentu rinfurzatu è sustenibilità.

U viaghju di u PVC da un compostu simplice à una commodità glubale hè un testimoniu di l'ingenuità umana è a nostra capacità di furmà materiali chì, à u turnu, formanu u nostru mondu.

A chimica di u PVC

Per capisce veramente u PVC, andemu in u mondu di a chimica. E proprietà uniche è versatilità di PVC sò u risultatu di a so struttura moleculare è di i prucessi chimichi chì u creanu.

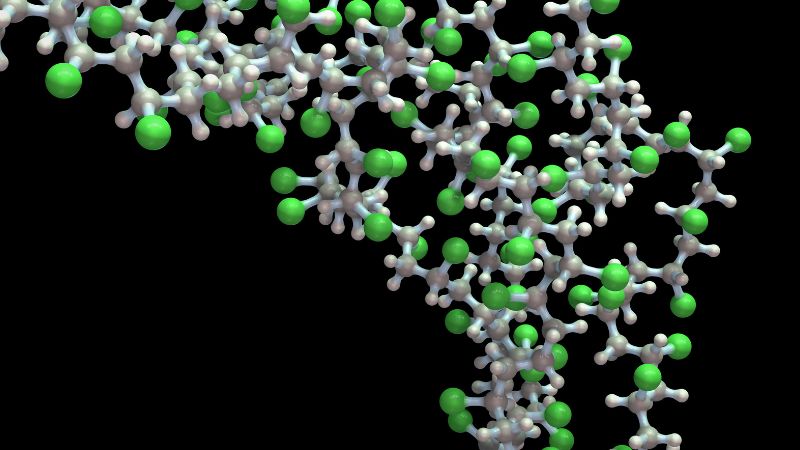

A cumpusizioni chimica: In u so core, u PVC hè un polimeru, chì hè una grande molécula composta da unità ripetute più chjuche chjamate monomeri. Per PVC, u monomeru hè u cloruru di vinile, un compostu simplice custituitu di atomi di carbonu, idrogenu è cloru. A so formula chimica hè C2H3Cl.

U rolu di u cloru: Una di e caratteristiche distintive di PVC hè a prisenza di atomi di cloru in a so struttura. Questi atomi di cloru cuntribuiscenu significativamente à e proprietà di PVC. U cloru hè elettronegativu, chì significa chì hà una forte attrazione per l'elettroni. In u risultatu, a prisenza di l'atomi di cloru in u PVC rende inherentemente resistente à a fiamma è menu prubabile di sustene a combustione. Questu hè un mutivu chjave perchè u PVC hè largamente utilizatu in l'applicazioni induve a sicurità di u focu hè una preoccupazione, cum'è l'insulazione di cablaggio elettricu. Inoltre, l'atomi di cloru in PVC furnisce a resistenza chimica, facendu assai resistente à parechji acidi, basi è chimichi.

Diverse forme di PVC: PVC pò piglià diverse forme sicondu u gradu di polimerizazione è l'aghjunzione di plastificanti è altri additivi. U PVC rigidu, cunnisciutu cum'è PVC-U, hè robustu è spessu usatu in a custruzzione di tubi, raccordi è cornici di finestra. U PVC flessibile, chjamatu PVC-P, hè utilizatu per prudutti cum'è tubi medichi è insulazioni di cavi.

Tipi è gradi di PVC

PVC vene in diversi tipi è gradi, ognunu adattatu per applicazioni specifiche. Esplora queste classificazioni è e so caratteristiche uniche.

1. PVC-U (PVC non plastificato):

- Pruprietà: Rigidu, eccellente resistenza chimica, alta forza meccanica, resistente à a fiamma, adattatu per l'usu esternu.

- Applicazioni: Tubi d'acqua è fognature, cornici di finestra, canali di cavi, tanki industriali è equipaghji.

2. PVC-P (PVC plastificatu):

- Pruprietà: Flessibule, bon isolamentu elettricu, resistente à l'olii è i sustanzi chimichi, resistente à a fiamma, adattatu per ambienti friddi.

- Applicazioni: Tubi medichi, insulazioni di cavi elettrici, strutture gonfiabili (per esempiu, ghjoculi è materassi d'aria), tubi flessibili è cortini.

3. PVC-C (PVC cloru):

- Pruprietà: Eccellente resistenza à alta temperatura, resistenza chimica superiore, proprietà meccanica rinfurzata paragunatu à PVC-U, resistente à a fiamma.

- Applicazioni: Equipaghji di trasfurmazioni chimichi, sistemi di ventilazione per ambienti corrosivi, tubi à alta temperatura è raccordi.

4. PVC spumatu:

- Pruprietà: Ligeru, bassa densità, boni proprietà d'insulazione, resistente à u clima, resistente à l'impattu.

- Applicazioni: Segnaletica è pannelli di publicità, pannelli di visualizazione, fabbricazione di mudelli è decorazioni interni.

5. PVDC (Clorur di Polyvinylidene):

- Pruprietà: Proprietà di barriera eccezziunale à i gasi è l'umidità, eccellente resistenza chimica, trasparente, bona resistenza à u calore.

- Applicazioni: Imballaggi alimentari (per esempiu, Saran Wrap), rivestimenti per imballaggi blister, strati protettivi per film flessibili.

6. CPVC (Cloruro di polivinile cloru):

- Pruprietà: Resistenza à u calore rinfurzata paragunatu à PVC-U, bona resistenza chimica, resistenza à fiamma, forti proprietà meccaniche, adattate per a distribuzione d'acqua calda.

- Applicazioni: Tubi d'acqua calda è raccordi, sistemi di sprinkler di u focu, pipeline di trasfurmazioni chimiche.

7. UPVC (Clorur di Polivinile Unplasticized):

- Pruprietà: Rigidu, durable, eccellente resistenza à l'intemperie è a radiazione UV, mantenimentu bassu, bona stabilità dimensionale.

- Applicazioni: Materiali di tetti, grondaie è downspouts, mobili esterni, rivestimenti è rivestimenti.

Questi diversi tipi è gradi di PVC offrenu à i disinfettori è à l'ingegneri a flessibilità di sceglie u materiale più adattatu per e so applicazioni specifiche, sia per a so resistenza chimica, proprietà elettriche, flessibilità o resistenza à a temperatura.

Pruprietà di PVC

Polyvinyl Chloride (PVC) hè rinumatu per a so cumminazione unica di pruprietà, facendu un materiale versatile cù una larga gamma di applicazioni. In questu capitulu, andemu ind'è e proprietà fisiche è chimiche chjave chì definenu u PVC.

1. Durabilità: Una di e caratteristiche di u PVC hè a so durabilità. Puderà sustene e cundizioni ambientali duri, cumprese l'esposizione à u sole, l'umidità è i sustanzi chimichi, senza degradazione significativa. Questu rende u PVC una scelta populari per l'applicazioni outdoor è di longa durata.

2. Resistenza di fiamma: U PVC hè intrinsecamente resistente à a fiamma. Hà una alta temperatura di ignizione è ùn sustene micca facilmente a combustione. Quandu s'hè esposta à fiamme, tende à autoestingue, chì hè una funzione di salvezza cruciale. In u risultatu, u PVC hè comunmente utilizatu in a custruzzione, u filatu elettricu è u trasportu induve a sicurità di u focu hè una preoccupazione.

3. Resistenza chimica: PVC hè assai resistente à parechji acidi, basi è chimichi. Ùn si corrode o degrada quandu hè esposta à una larga gamma di sustanzi, facendu una scelta ideale per l'equipaggiu di trasfurmazioni chimichi, sistemi di tubazioni è cuntenituri.

4. Pruprietà di l'insulazione elettrica: PVC hè un eccellente insulatore elettricu. Havi una conductività elettrica bassa, facendu adattatu per l'usu in cablaggi elettrici è insulazioni di cavi. Inoltre, a so resistenza à u focu hè vantaghju in l'applicazioni elettriche induve a sicurità di u focu hè di primura.

5. Forza meccanica: U PVC rigidu, in particulare, mostra una forza meccanica impressiunanti. Pò sustene carichi è impatti sustanziali, facendu un materiale preziosu in l'applicazioni di custruzzione è strutturali.

6. Stabilità termale: PVC hà una bona stabilità termale, mantenendu e so proprietà à una larga gamma di temperature. PVC-C, una forma clorurata di PVC, hè sopratuttu cunnisciuta per a so resistenza à alta temperatura è pò manighjà temperature elevate cumparatu cù u PVC standard.

7. Resistenza à l'acqua: U PVC hè intrinsecamente impermeabile, per quessa hè spessu usatu in sistemi di fontaneria è di distribuzione d'acqua. Ùn corrode micca o debilitatu quandu espunutu à l'acqua, facendu una scelta affidativa per queste applicazioni.

8. Versatilità: A versatilità di PVC hè una caratteristica spiccata. Ajustendu i metudi di formulazione è trasfurmazioni, pò esse trasfurmatu in materiali rigidi o flessibili, adattati per appiicazioni specifiche. Questa adattabilità hè un mutivu chjave perchè u PVC trova l'usu in una varietà cusì larga di industrii.

9. Riciclabilità: U PVC hè riciclabile, è i sforzi per migliurà a so sustenibilità sò in corso. Mentre chì ci sò stati preoccupazioni annantu à l'impattu ambientale di u PVC in u passatu, l'avanzamenti in u riciclamentu è e pratiche di fabricazione sustinibili sò affruntendu questi prublemi.

E proprietà uniche di PVC facenu un materiale di scelta in numerosi industrii, da a custruzzione è a salute à l'automobile è oltre. A so durabilità, a resistenza di fiamma, a stabilità chimica è l'adattabilità cuntinueghjanu à fà u PVC un asset preziosu in l'ingegneria è u disignu.

Prucessu di fabricazione di PVC

U viaghju di Polyvinyl Chloride (PVC) da a so materia prima à u materiale versatile chì sapemu oghje hè un affascinante. In questu capitulu, scopreremu i prucessi di fabricazione implicati in a produzzione di PVC è cumu si formanu e so proprietà.

1. Polimerizazione: U viaghju di PVC principia cù a polimerizazione di monomeri di cloru di vinile. Stu prucessu implica a cunnessione di e molécule di cloruru di vinile inseme per formate catene longu. Ci sò parechji metudi di polimerizazione utilizati in a produzzione di PVC:

- Polimerizazione in sospensione: Stu metudu implica a sospensione di gocce di cloruru di vinile in l'acqua è poi inizià u prucessu di polimerizazione cù u calore è un catalizzatore.

- Polimerizzazione in emulsione: Quì, u cloru di vinile hè polimerizatu in una emulsione aquosa, creendu un materiale di lattice.

- Polimerizzazione in massa: In questu metudu, u cloru di vinile hè polimerizatu in una forma pura, senza diluzione.

2. Produzzione di resina: U polimeru risultatu, spessu chjamatu resina di PVC, hè sottumessu à un prucessu ulteriore. Duranti stu stadiu, l'additivi sò intrudutti per rinfurzà e proprietà specifiche. L'additivi cumuni includenu plastificanti per fà u PVC flexible, stabilizzatori per prevene a degradazione, pigmenti per a colorazione, è riempitivi per migliurà a forza è riduce u costu.

3. Mixing and Compounding: A resina di PVC hè mischjata cù additivi in proporzioni precise cù miscelatori d'alta velocità. Stu prucessu assicura chì l'additivi sò distribuiti uniformemente in tutta a matrice di PVC.

4. Estrusione o Molding: U compostu di PVC hè allora alimentatu in un extruder o macchina di molding, induve hè riscaldatu è furmatu in a forma desiderata. L'estrusione hè aduprata per prudutti cum'è tubi, profili è fogli, mentre chì l'estrusione hè impiegata per disinni più intricati.

5. Cooling and Cutting: Dopu l'extrusion o l'molding, i prudutti di PVC sò rinfriscati per stabilisce a so forma. Puderanu ancu esse tagliati à a lunghezza o forma desiderata.

6. Control di qualità: E misure di cuntrollu di qualità sò integrali à a fabricazione di PVC. I prudutti sò sottumessi à diverse teste per assicurà chì rispondenu à i standard di l'industria per e proprietà cum'è a precisione dimensionale, a forza di trazione è a resistenza chimica.

7. Imballaggio è Distribuzione: Una volta chì i prudutti di PVC passanu u cuntrollu di qualità, sò imballati è distribuiti à i so mercati è industrii destinati.

A fabricazione di PVC hè un prucessu altamente cuntrullatu chì permette a persunalizazione di i prudutti di PVC per risponde à esigenze specifiche. L'scelta di l'additivi, u metudu di polimerizazione è e cundizioni di trasfurmazioni ghjucanu un rolu in a furmazione di e proprietà finali di PVC.

Applicazioni di PVC

Polyvinyl Chloride (PVC) s'hè stabilitu cum'è un materiale di versatilità eccezziunale, truvendu applicazioni in una larga gamma di industrii. A so cumminazzioni unica di pruprietà u rende indispensabile in diversi cuntesti. In questu capitulu, esploreremu i roli diversi è vitali di PVC in a nostra vita di ogni ghjornu.

1. Industria di custruzzione:

- Tubi è raccordi: I tubi di PVC sò largamente usati per a distribuzione d'acqua, drenaje è sistemi di fognatura. Sò ligeri, resistenti à a corrosione, è anu una longa vita di serviziu.

- Cornici di finestra: E proprietà isolanti di PVC facenu una scelta populari per i cornici di finestra. Aiuta à migliurà l'efficienza energetica è riduce i costi di riscaldamentu è di raffreddamentu.

- Profili è Siding: I profili di PVC sò usati per porte, cornici è rivestimenti per via di a so resistenza à l'intemperie, i danni di termite è a decadenza.

2. Settore di a Salute:

- Tubi medichi: U PVC flessibile hè utilizatu per i tubi medichi, cum'è linee intravenose (IV), cateteri è sistemi di consegna d'ossigenu per via di a so biocompatibilità è flessibilità.

- Imballaggio medico: U PVC hè utilizatu in l'imballa di i farmaceutichi è di i dispositi medichi, chì furnisce una barriera contru a contaminazione.

3. Applicazioni Automotive:

- Interni di l'automobile: U PVC hè utilizatu in l'internu di e vitture per i coperchi di u dashboard, i materiali di seduta è i pavimenti per via di a so durabilità è facilità di mantenimentu.

- Cablaggio e cablaggio: U PVC hè impiegatu in l'insulazione di u filatu di l'automobile, induve e so proprietà d'insulazione elettrica sò critiche.

4. Elettricu è Elettronica:

- Isolamentu di u cable: PVC hè utilizatu per insulate i cables elettrici, assicurendu a trasmissione sicura di l'electricità.

- Rivestimenti di filu: Hè aduprata per i rivestimenti di filu, prutegge contra l'usura è i fatturi ambientali.

5. Segnale è Grafica:

- Segnale in vinile: I fogli di vinile basatu in PVC sò usati per segni publicitarii, banners è decals per via di a so durabilità è a capacità di mantene stampe vibranti.

6. Imballaggi è Beni di cunsumu:

- Imballaggio blister: U PVC hè adupratu in l'imballaggi blister per i farmaceutichi è i beni di cunsumu per via di e so proprietà di trasparenza è barriera.

- Cancelleria è ghjoculi: U PVC hè utilizatu per l'articuli di cartoleria, i ghjoculi è i prudutti gonfiabili per via di a so facilità di modellazione è flessibilità.

7. Agriculture :

- I tubi è i raccordi di PVC sò largamente usati in l'agricultura per i sistemi di irrigazione è a distribuzione d'acqua in splutazioni.

8. Applicazioni miscellaneous:

- Calzature: U PVC hè utilizatu in a produzzione di calzature, cumpresi stivali di pioggia è sandali, per via di e so proprietà resistenti à l'acqua.

- Attrezzatura sportiva: Hè adupratu per articuli cum'è balli sportivi è strutture gonfiabili.

- Marina è imbarcazioni: U PVC hè impiegatu in l'applicazioni marine cum'è i battelli gonfiabili è e boe per via di a so flottabilità è a resistenza à l'acqua salata.

A versatilità rimarchevule di PVC hè in piena manifestazione in i numerosi roli chì ghjucanu in diverse industrie. Da rinfurzà a sicurità è u cunfortu di e nostre case à cuntribuisce à l'avanzamenti in a salute è u trasportu, u PVC cuntinueghja à evoluzione è innuvà, assicurendu chì ferma un materiale essenziale in u nostru mondu mudernu.

Considerazioni Ambientali

Mentre esploremu u mondu di u Cloruro di Polivinile (PVC), hè essenziale per cunsiderà l'impattu ambientale di stu materiale versatile. U PVC hà affruntatu scrutinu è dibattitu annantu à l'anni per via di i so prucessi di produzzione è di l'effetti potenziali ambientali. In questu capitulu, esamineremu sia e preoccupazioni è i sforzi di sustenibilità in l'industria di PVC.

1. Pruduzzione è emissioni di gas di cloru:

Unu di i prublemi ambientali primari assuciati à a produzzione di PVC hè a liberazione di gas di cloru. Durante u prucessu di fabricazione, in particulare in i primi fasi di a produzzione di PVC, u gasu di cloru hè pruduttu cum'è un subproduttu. U cloru hè un gas altamente reattivu è potenzialmente periculosu, è e so emissioni anu suscitatu preoccupazioni ambientali. In ogni casu, hè impurtante nutà chì avanzamenti significativi sò stati fatti in a tecnulugia di produzzione di PVC. E strutture muderne anu implementatu misure per catturà è neutralizà l'emissioni di cloru, riducendu u so impattu ambientale.

2. Riciclamentu di PVC:

U PVC hè riciclabile, ma presenta alcune sfide paragunate à l'altri plastichi. Una sfida hè a prisenza di diversi additivi in i prudutti di PVC, chì ponu complicà u prucessu di riciclamentu. Per affruntà questu, i prugrammi di riciclamentu per u PVC anu migliuratu annantu à l'anni, facendu sempre più viable è ecologicu.

3. Analisi di u Ciclu di Vita:

L'impattu ambientale di u PVC hè assai dipendente da u so ciclu di vita. Fattori cum'è a produzzione, u trasportu, l'usu è l'eliminazione cuntribuiscenu à l'impronta ambientale generale di i prudutti PVC. L'analisi di u ciclu di vita hè un strumentu preziosu per valutà questi impatti è identificà e zone per migliurà.

4. Ftalati è preoccupazioni per a salute:

I ftalati sò un gruppu di sustanzi chimichi chì sò spessu usati cum'è plastificanti in formulazioni di PVC. Ci hè stata preoccupazione per a lixiviazione potenziale di ftalati da i prudutti di PVC, in particulare in i ghjoculi è i dispositi medichi. Per affruntà queste preoccupazioni, ci hè una tendenza à sviluppà formulazioni di PVC senza ftalati.

5. Dioxins è Incinerazione:

A pruduzzione è l'incinerazione di PVC pò esse risultatu in a liberazione di diossine, composti altamente tossichi. Rigulamenti stretti è prucessi di produzzione migliurati anu riduciutu significativamente l'emissioni di diossina. A gestione curretta di i rifiuti è i sforzi di riciclamentu sò essenziali per minimizzà l'impattu ambientale di u PVC incineratu.

Polyvinyl Chloride (PVC) hè un materiale versatile cù un inseme cumplessu di considerazioni ambientali. Mentre esistenu sfide, l'industria di PVC hà fattu un prugressu sustanziale in affruntà i prublemi ambientali. L'innuvazioni in a tecnulugia di produzzione, e pratiche di riciclamentu è u sviluppu di formulazioni di PVC più sustenibili cuntribuiscenu à riduce l'impattu ambientale di u PVC.

Vantaghji è svantaghji putenziali di PVC

Polyvinyl Chloride (PVC) hè un materiale cù una storia ricca è una vasta gamma di applicazioni. In questu capitulu, esamineremu sia i vantaghji chì anu propulsatu u PVC à a prominenza è i putenziali inconvenienti chì anu suscitatu dibattiti è purtatu à migliuramentu cuntinuu.

Vantaghji di PVC

- Versatilità: U PVC hè incredibbilmente versatile, è e so proprietà ponu esse adattate per adattà à diverse applicazioni. Da u PVC rigidu utilizatu in a custruzzione à u PVC flexible in i dispositi medichi, pò esse adattatu per risponde à i bisogni specifichi.

- Durabilità: U PVC hè rinumatu per a so durabilità è a longa vita di serviziu. Pò resiste à e cundizioni ambientali duri, facendu ideale per l'applicazioni outdoor.

- Resistenza à a fiamma: A resistenza inerente di a fiamma di u PVC è e proprietà auto-estinguenti facenu una scelta sicura in applicazioni induve a sicurezza di u focu hè una preoccupazione.

- Resistenza chimica: U PVC hè assai resistente à parechji acidi, basi è chimichi, assicurendu a so longevità in ambienti corrosivi.

- Isolamentu Elettricu: Hè un insulatore elettricu eccellente, facendu adattatu per l'insulazione di cablaggio è cable.

- Costu efficace: U PVC hè spessu costu-efficace cumparatu cù materiali alternattivi, chì cuntribuisci à u so usu generalizatu in diverse industrii.

Inconvenienti putenziali di PVC

- Pruduzzione di cloru: A pruduzzione di PVC implica l'usu di u gasu di cloru, chì hà suscitatu preoccupazioni ambientali. Mentre l'emissioni sò state ridutte significativamente per via di a tecnulugia mejorata, questu resta un puntu di dibattitu.

- Impattu Ambientale: L'impattu ambientale di PVC dipende da parechji fatturi, cumpresu u so ciclu di vita. E preoccupazioni includenu l'eliminazione di i prudutti di PVC è u putenziale di emissioni tossiche se incinerate.

- Preoccupazioni di salute: Certi studii anu suscitatu prublemi di salute in relazione à u PVC, in particulare in quantu à a liberazione di ftalati è diossine durante a fabricazione o l'eliminazione. Queste preoccupazioni anu purtatu à sforzi per sviluppà formulazioni senza ftalati è più ecologiche.

- Sfide di riciclamentu: Mentre u PVC hè riciclabile, presenta sfide in u riciclamentu per a presenza di diversi additivi. Separà u PVC da altri plastichi pò esse cumplessu, ma i prugrammi di riciclamentu sò in continuazione.

- Rigidità è fragilità: U PVC rigidu pò esse fragile à bassa temperatura, chì pò limità u so usu in cundizioni freti estremi.

L'usu di PVC implica un scambiu trà i so vantaghji è i so svantaghji. I prufessiunali di l'industria, i pulitici è i cunsumatori anu da cunsiderà questi fattori quandu sceglie PVC per applicazioni specifiche. L'avanzati in tecnulugia, riciclamentu è iniziative di sustenibilità in l'industria di PVC miranu à affruntà i prublemi ambientali è di salute, rinfurzendu ancu u so valore.

Cunsiderazioni di Sicurezza è Salute

L'aspettu di sicurezza è salute di u Cloruro di Polivinile (PVC) sò cunsiderazioni cruciali, soprattuttu datu u so usu diffusa in diverse industrii. In questu capitulu, sfonderemu in e misure di sicurezza, i regulamenti è i prublemi di salute potenziali assuciati cù PVC.

Misure di sicurezza in a manipulazione di PVC

- Prutezzione respiratorie: Quandu travaglianu cù PVC in ambienti di fabricazione o di trasfurmazioni, i travagliadori puderanu avè bisognu di utilizà a prutezzione respiratoria, cum'è maschere o respiratori, per evità di inalazione di particelle o fumi in l'aria.

- Prutezzione di a pelle: I vestiti protettivi, i guanti è i vetri di sicurezza o l'occhiali sò cunsigliati per minimizzà u cuntattu di a pelle è l'esposizione di l'ochji à i materiali PVC, in particulare durante i prucessi di taglio, macinazione o saldatura.

- Ventilazione: Sistemi di ventilazione adattati sò cruciali per cuntrullà è caccià ogni emissione potenziale o fumi generati durante u prucessu di produzzione di PVC.

- Manipulazione è Conservazione: I materiali di PVC devenu esse manipulati è almacenati secondu e raccomandazioni di u fabricatore per minimizzà u risicu di ferite fisiche è assicurà e cundizioni di almacenamentu sicuru.

Regolamenti è Norme

- Amministrazione per a Salute è a Sicurezza Occupazionale (OSHA): OSHA in i Stati Uniti stabilisce e regule di sicurezza di u travagliu chì ponu applicà à a manipulazione è l'usu di PVC. I patroni sò rispunsevuli di assicurà u rispettu di sti regulamenti per prutege i so impiegati.

- Regolamenti Ambientali: L'agenzii ambientali in parechji paesi regulanu l'emissioni è l'eliminazione di materiali PVC-related, in particulare in quantu à a liberazione di gas di cloru è u putenziale impatti ambientali.

Preoccupazioni di salute

- Esposizione di gas di cloru: Unu di i prublemi di salute primari assuciati à u PVC hè a liberazione potenziale di gas di cloru durante a produzzione o in casu d'incendiu. L'esposizione à u gasu di cloru pò causà irritazione respiratoria è oculare, è in alta concentrazione pò esse tossica.

- ftalati: I ftalati sò un gruppu di sustanzi chimichi chì sò spessu usati cum'è plastificanti in formulazioni di PVC. Ci sò stati prublemi di salute in quantu à a liberazione di ftalati da i prudutti di PVC, in particulare in i ghjoculi è i dispositi medichi. In u risultatu, ci hè una tendenza à sviluppà formulazioni di PVC senza ftalati.

- Diosine: A pruduzzione è l'incinerazione di PVC pò esse risultatu in a liberazione di diossine, chì sò composti altamente tossichi. I rigulamenti stretti è i prucessi di produzzione migliurati anu riduciutu l'emissioni di diossina, ma u monitoraghju è u cuntrollu sò preoccupazioni cuntinui.

PVC in l'assistenza sanitaria

In a salute, u PVC hè largamente utilizatu per i dispositi medichi è l'imballaggi. A sicurità di PVC in l'applicazioni mediche hè un sughjettu di scrutiniu. I sforzi sò fatti per assicurà chì i prudutti medichi in PVC rispondenu à i normi regulatori è minimizzà i risichi potenziali per a salute per i pazienti.

Cunsiderazioni di sicurità è salute sò di primura in l'usu di PVC, in particulare in industrii induve i travagliadori o i cunsumatori ponu entra in cuntattu cù i materiali PVC. L'aderenza stretta à e misure di sicurezza, u rispettu di i regulamenti è a ricerca in corso in i prublemi di salute potenziali sò essenziali per assicurà l'usu sicuru di PVC in diverse applicazioni.

U futuru di u PVC – Innuvazione è sustenibilità

Polyvinyl Chloride (PVC) hà fattu una longa strada da a so scuperta, evoluzione in un materiale versatile cù diverse applicazioni. Mentre guardemu à u futuru, parechji tendenzi è sviluppi chjave sò pronti à furmà u rolu di PVC in u nostru mondu.

1. Pratiche sustinibili è ecunumia Circular

L'industria di PVC travaglia attivamente per rinfurzà a sustenibilità è riduce l'impatti ambientali. Eccu cumu:

- Iniziative di riciclamentu: I prugrammi di riciclamentu per u PVC cuntinueghjanu à espansione. U riciclamentu di materiali PVC ùn solu cunserva e risorse, ma aiuta ancu à riduce i rifiuti in i discaricamenti.

- Formulazioni senza ftalati: Ci hè un cambiamentu crescente versu u sviluppu è l'usu di formulazioni di PVC senza ftalati, affruntendu i prublemi di salute è allineendu cù e preferenze di i cunsumatori per i prudutti più sicuri.

- Additivi biodegradabili: A ricerca hè in corso per incorpore additivi biodegradabili in formulazioni di PVC, chì permette à i prudutti di PVC di scumpressà più facilmente à a fine di u so ciclu di vita.

- Chimica verde: U sviluppu di prucessi di produzzione PVC è additivi più amichevuli di l'ambiente hè un focusu di a ricerca in corso.

2. Innuvazioni tecnulogichi

L'avanzamenti in a tecnulugia PVC aprenu novi pussibulità:

- Materiali Smart PVC: L'innovazioni in l'additivi di u PVC è i cumposti permettenu u sviluppu di “intelligente” materiali cù proprietà rinfurzate, cum'è capacità d'auto-guarigione è conducibilità elettrica mejorata.

- Nanotecnologia: L'incorporazione di nanomateriali in formulazioni di PVC aumenta e caratteristiche di rendiment, rendendu u PVC ancu più adattabile è efficiente.

3. Cunsigliu Regulatory

Siccomu e preoccupazioni per l'impatti ambientali è di salute persistanu, i standard regulatori è e certificazioni di l'industria sò previsti per diventà più stretti. I pruduttori di PVC sò prubabilmente invistisce à risponde à questi standard per assicurà a sicurezza è a sustenibilità di i so prudutti.

4. Espansione Globale

A versatilità è u costu di PVC facenu un materiale preziosu in e economie emergenti. Siccomu u sviluppu di l'infrastruttura è l'urbanizazione cuntinueghjanu à cresce in u mondu, a dumanda glubale di PVC hè prevista per aumentà, in particulare in l'applicazioni di custruzzione è di salute.

5. Pratichi Sustainable Building

In l'industria di a custruzione, ci hè un focusu crescente nantu à e pratiche di custruzzione sustinibili. I prudutti di PVC, cum'è e finestre efficienti d'energia è e membrane di tetti in PVC, cuntribuiscenu à a cunservazione di l'energia è a sustenibilità, allineendu cù u muvimentu di l'edificazione verde.

Polyvinyl Chloride (PVC) hà un futuru promettente, guidatu da sforzi continui per migliurà a sustenibilità, a sicurità è u rendiment. L'industria di u PVC hè impegnata à affruntà i prublemi ambientali, riducendu a so impronta di carbonu, è abbraccianu l'innovazioni tecnologiche.

Siccomu u PVC cuntinueghja à adattà à e dumande è e regule cambianti, prubabilmente resterà un materiale vitale in una larga gamma di industrii. A so versatilità, a durabilità è l'efficacità di u costu assicuranu chì u PVC ghjucà un rolu significativu in a furmazione di u nostru mondu, avà è in u futuru.

Conclusioni: PVC – Un materiale versatile chì modella u nostru mondu

In a grande tappezzeria di materiali chì tessenu u nostru mondu mudernu, Polyvinyl Chloride (PVC) hè un filu notevuli. Da i so umili origini cum'è un esperimentu cù u gasu di cloru è u cloru di vinile, u PVC hà evolutu in un materiale versatile, durable è adattabile chì tocca quasi ogni aspettu di a nostra vita.

Cume avemu viaghjatu à traversu i capituli di sta guida cumpleta, avemu vistu u viaghju di PVC da u so principiu à u so rolu pivotale in a custruzzione, a salute, l'automobile è innumerevoli altre industrie. Avemu esploratu a so chimica unica, a so larga gamma di tipi è gradi, è e proprietà notevuli chì a rende indispensabile. Avemu discututu e so considerazioni ambientali, i vantaghji, i svantaghji potenziali, è i sforzi in corso per rende più sustinibili è sicuru.

U PVC hè più cà solu un materiale, hè un testimoniu di l'ingegnu umanu è l'innuvazione. Riflette a nostra capacità di sfruttà l'elementi è e soluzioni di l'ingegneria chì aumentanu a nostra qualità di vita. U PVC ùn hà micca solu furmatu u nostru mondu, ma cuntinueghja à fà cusì, grazia à a ricerca, u sviluppu è l'impegnu di l'industrii è di l'individui à aduprà in modu rispunsevule.

Mentre guardemu à u futuru, u PVC hè prontu à evoluzione ulteriormente, abbracciandu a sustenibilità, l'innuvazione è u rispettu di i rigulamenti stretti. Continuerà à adattà per risponde à i bisogni di un mondu cambiante, cuntribuiscenu à a nostra sicurezza, cunfortu è prugressu.

Dunque, sia i tubi di PVC chì portanu l'acqua pulita à e nostre case, i tubi di PVC flessibili chì salvanu vite in ambienti medichi, o i cornici di finestre in PVC durable chì aumentanu l'efficienza energetica, u PVC resta una parte integrante di u tissutu di a nostra sucietà muderna.

Cum'è ci dicemu addiu à questa esplorazione di PVC, vi invitemu à stà curiosu, à cuntinuà à innuvà, è à apprezzà a miriade di modi in quale materiali cum'è PVC formanu u mondu intornu à noi. U viaghju di scuperta ùn finisce mai, è a storia di PVC hè luntanu da esse finita.